Primary steel

Primary steel

Was ist Primary Steel?

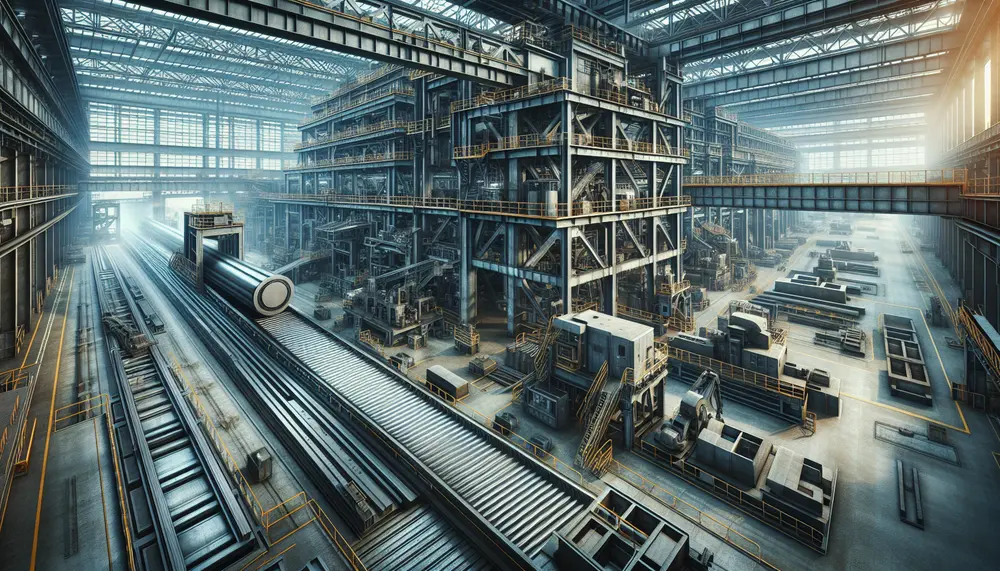

'Primary Steel' ist ein Fachbegriff, der in der Steel production und im Steel trade verwendet wird. Es handelt sich dabei um Stahl, der aus rohem Eisen, auch bekannt als Eisenerz, erzeugt wird. Eine der bekanntesten Methoden zur Herstellung von Primary Steel ist der Hochofenprozess.

Der Herstellungsprozess

Die Herstellung von Primary Steel beginnt mit der Verarbeitung von Eisenerz. Das Erz wird zuerst in einem Hochofen geschmolzen. Dabei wird Koks, ein Kohleprodukt, hinzugegeben, der als Reduktionsmittel dient und den Sauerstoff aus dem Eisenerz entfernt. Das Ergebnis ist Rohstahl, auch 'Primary Steel' genannt.

Zusätzliche Prozesse

Nach der Herstellung durchläuft der Primary Steel weitere Veredelungsprozesse. Das kann das Entfernen von Unreinheiten, das Legieren mit anderen Metallen oder das Härten beinhalten, je nachdem, welche Eigenschaften der fertige Stahl haben soll.

Verwendung von Primary Steel

Primary Steel ist vielseitig verwendbar. Er wird in vielen Bereichen eingesetzt, darunter auch im Bauwesen und im Automobilbau. Aber auch für Produkte wie Werkzeuge, Maschinen und Haushaltsgeräte kommt er häufig zum Einsatz.

Fazit

Der Prozess der Herstellung von Primary Steel ist sowohl komplex als auch interessant. Er beginnt mit der Reduktion von Eisenerz in einem Hochofen und endet mit einem vielseitig verwendbaren Produkt. Der Begriff 'Primary Steel' ist in der Stahlproduktion und im Stahlhandel von zentraler Bedeutung, da er den Ausgangspunkt für eine Vielzahl von Produkten und Anwendungen darstellt.

Blog Posts with the term: Primary steel

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

India's steel industry utilizes rich iron ore resources and advanced technology, adopting innovative methods like automation for efficient production. Government policies support sustainable practices in this key economic sector that drives growth and employment....

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...

Steel making transforms iron ore into steel using blast furnaces or electric arc furnaces, involving processes like smelting and carbon adjustment to achieve desired properties. The production includes primary methods like Basic Oxygen Steelmaking and Electric Arc Furnace, followed by...

Steel production relies on a balance of raw materials like iron ore, coal, limestone, and scrap metal to determine the characteristics of different steel types. Understanding these ingredients is crucial for industry professionals as they influence strength, durability, and quality...

Steel manufacturing is a complex, multi-stage process that transforms raw materials into the durable metal essential for modern infrastructure. It begins with extracting iron ore and progresses through various phases including blast furnace operation and primary steelmaking methods like Basic...

The VAD steelmaking process, or Vacuum Arc Degassing, is crucial for producing high-quality steel by removing impurities and gases like hydrogen and nitrogen through a vacuum environment, resulting in purer and more homogeneous steel with enhanced mechanical properties....

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...