Product development

Product development

Im Zusammenhang mit der Stahlproduktion und dem Stahlhandel ist der Begriff Product development, auf Deutsch "Produktentwicklung", von zentraler Bedeutigkeit. Dieser Prozess ist ein gezieltes Vorgehen, bei dem Innovationen und Verbesserungen bei bestehenden oder neuen Stahlprodukten erzielt werden sollen.

Was ist Produktentwicklung?

Product development bezeichnet in der Stahlindustrie den gezielten Prozess, um Verbesserungen bei bestehenden oder neuen Stahlprodukten zu erreichen. Hierbei spielen viele Faktoren eine Rolle, wie zum Beispiel technologische Fortschritte, gestalterische Verbesserungen oder auch die Bedürfnisse der Kunden. Ziel ist es, ein qualitativ hochwertigeres oder gänzlich neues Stahlprodukt zu entwickeln und auf den Markt zu bringen.

Warum ist Produktentwicklung wichtig?

Die Produktentwicklung ist nicht nur ein wichtiger Bestandteil der Innovationskraft von Stahlunternehmen, sondern auch entscheidend für die Wettbewerbsfähigkeit auf dem Markt. Sie ermöglicht es Unternehmen, neue Märkte zu erschließen, auf veränderte Marktanforderungen zu reagieren und Kundenzufriedenheit zu steigern.

Prozess der Produktentwicklung

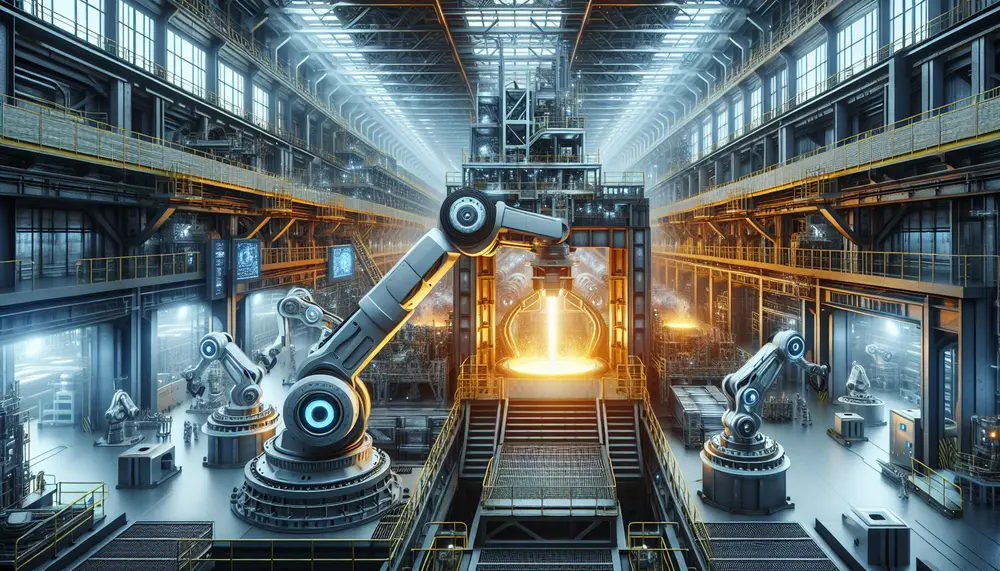

Der Prozess der Produktentwicklung ist meist in mehreren Phasen unterteilt. Er beginnt in der Regel mit einer Ideensammlung und Marktanalyse, gefolgt von der Entwicklung des Produktdesigns und Prozessplanung. Danach folgt die Produktionsphase, in der das Produkt hergestellt wird. Der Prozess endet mit der Markteinführung und dem Feedback der Kunden, das für zukünftige Entwicklungen genutzt wird.

Beispiele für Produktentwicklung in der Stahlindustrie

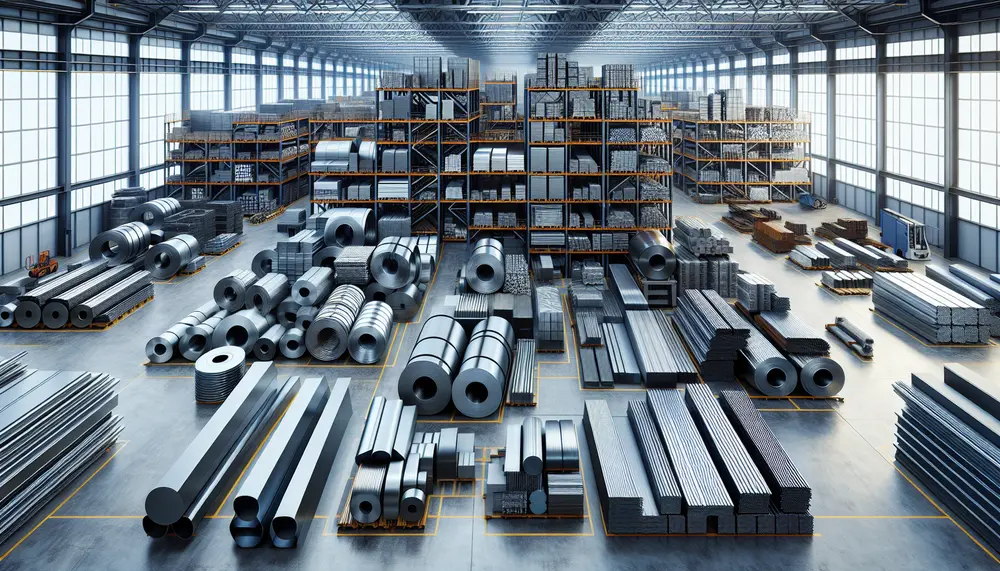

Ein gutes Beispiel für Produktentwicklung in der Stahlindustrie ist die Entwicklung von hochfesten Stählen. Diese wurden entwickelt, um die Anforderungen in Bereichen wie Fahrzeugbau, Schiffbau oder Brückenbau zu erfüllen. Ein weiteres Beispiel ist die Entwicklung von rostfreien Stählen, die in Umgebungen mit hoher Feuchtigkeit oder Salzbelastung eingesetzt werden können.

Alles in allem ist die Produktentwicklung ein integraler Bestandteil der Stahlindustrie, der es ermöglicht, auf die sich ständig ändernden Anforderungen des Marktes zu reagieren und eine ständige Verbesserung und Innovation der Stahlprodukte zu gewährleisten.

Blog Posts with the term: Product development

Oman's steel production has seen significant growth, contributing to the nation's GDP and infrastructure development. Strategic expansions have increased capacity to over 2.4 million tons, with key players like Muscat Steel Industries Co. LLC driving this dynamic sector forward through...

Turkey's steel industry is a key economic pillar, known for its high-quality production and strategic location that bridges Europe and Asia. Despite challenges like raw material dependency and global price fluctuations, the sector has shown resilience through innovation and contributes...

The steel products market is a vital, diverse industry integral to various sectors and driven by demand for durable materials. It's influenced by global economic trends, technological advancements, sustainability efforts, and competitive factors such as cost management and regulatory compliance....

The steel production map is a visual tool that shows the global distribution of steel manufacturing, highlighting factors like location, capacity, and technology used. Key players in global steel include China, India, Japan, and the US; trends shaping the industry...

Steel plant products are essential in various industries and their sustainability is increasingly prioritized, focusing on eco-friendly manufacturing processes to reduce environmental impact. Innovations include efficient energy use, carbon capture technologies, and the development of new steel alloys for greener...

The steel making process at SAIL involves meticulous selection of raw materials and advanced technology in blast furnaces to produce molten iron, which is then refined using BOF or EAF methods. Rigorous quality control ensures the final product meets international...

Steelmaking without coal, utilizing electricity and hydrogen from renewable sources, offers a sustainable alternative to traditional methods by reducing carbon emissions. The shift towards green steel production is driven by innovations like electric arc furnaces and low-carbon materials, with industry...

The AM/NS steel making process integrates traditional methods with advanced technology, emphasizing sustainability by using electric arc furnaces for recycling scrap metal and implementing strict emission controls. This approach reflects the industry's shift towards more efficient and environmentally responsible production,...

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

The article discusses the state-wise analysis of steel production, highlighting how factors like resources, infrastructure, and policies influence each state's output. It emphasizes that such an overview provides insights into economic development patterns and helps stakeholders make informed decisions regarding...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Steelmaking transforms iron into steel by increasing carbon content and refining the material through methods like blast furnaces and adding additives. Modern techniques include Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), focusing on sustainability, with raw materials such...

The steel industry in Pakistan is integral to its economic growth, marked by increased local production and diversity of products due to domestic demand. Despite challenges like environmental concerns and reliance on imported raw materials, the sector has seen technological...

The steel products industry is entering a new era where brands are focusing on innovation, quality, and sustainability to meet higher customer expectations. Branding has become essential in differentiating companies within the market through trust, credibility, and unique selling propositions...