Steel mill

Steel mill

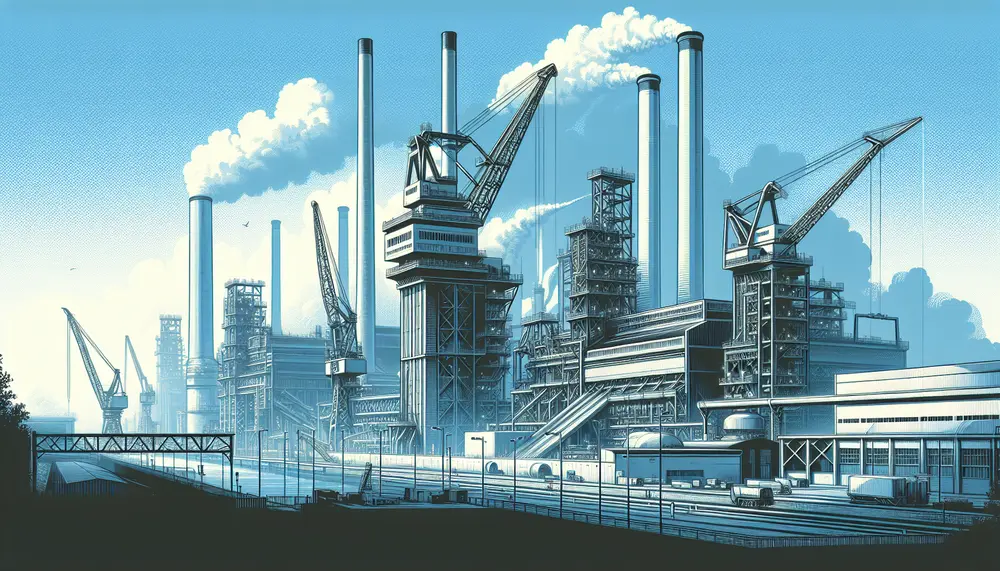

Was ist ein Steel Mill?

Ein Steel Mill, auch Stahlwerk genannt, ist ein großindustrieller Betrieb, in dem Stahl aus Eisen und anderen Roheisen erzeugt wird. Es ist der Ort, an dem der Prozess der Stahlherstellung stattfindet, einschließlich der Verarbeitung von Eisen-Erz zu Eisen und schließlich zu Stahl.

Die Rolle von Steel Mills in der Stahlproduktion

Steel Mills spielen eine zentrale Rolle in der Stahlproduktion. Sie setzen verschiedene Hochtemperaturprozesse ein, um aus Eisen-Erz und Kohle hochwertigen Stahl herzustellen. Ohne diese spezialisierten Werke gäbe es keinen Prozess zur Herstellung von Stahl - einem Material, das in einer Vielzahl von Industrien unverzichtbar ist, von der Bauindustrie bis hin zur Automobilindustrie.

Die Arten von Steel Mills

Es gibt verschiedene Arten von Steel Mills, einschließlich integrierter Stahlwerke und Mini-Stahlwerke. Integrierte Stahlwerke entwickeln den Stahl von Grund auf neu - vom Erz bis zum Endprodukt. Mini-Stahlwerke hingegen produzieren Stahl aus Schrotterzen und anderen sekundären Rohstoffen.

Steel Mills und Stahlhandel

Steel Mills sind ein entscheidender Teil des Stahlhandels. Sie stellen nicht nur Stahl her, sondern verkaufen ihn auch an Verbraucher und Händler weltweit. Dieser Handel variiert je nach dem aktuellen Bedarf und der Stahlproduktion, was ihn zu einem dynamischen und oft volatilen Markt macht. Vereinfacht gesagt, sind Steel Mills die Herzstücke des Stahlhandels.

Die Auswirkungen von Steel Mills auf die Umwelt

Es ist wichtig zu beachten, dass Steel Mills erhebliche Auswirkungen auf die Umwelt haben können. Diese Werke verbrauchen große Mengen an Energie und erzeugen beträchtliche Mengen an CO2-Emissionen. Aus diesem Grund sind umweltfreundliche Praktiken in der Stahlproduktion von entscheidender Bedeutung.

Blog Posts with the term: Steel mill

Steel production is vital in Anno 1800, requiring a strategic layout of mines and factories to efficiently transform iron ore into steel beams and weapons. Optimizing the placement and synchronization of these facilities ensures a smooth industrial operation essential for...

Nigeria's steel production industry is crucial for its industrial development, with potential to become a major producer due to iron ore deposits. However, the sector faces challenges such as small-scale operations and requires strategic solutions for sustainable growth. The evolution...

The African steel industry is growing and diverse, with varying levels of resource availability and technological sophistication across countries. It plays a crucial economic role by stimulating growth in other sectors, creating jobs, contributing to GDP, reducing import dependency, and...

The steel industry is essential but poses significant risks to workers, including physical dangers from heavy machinery and extreme heat, chemical hazards from toxic substances, burn threats due to high temperatures in furnaces, and noise pollution leading to potential hearing...

Steel production in France has grown due to technological advancements, increased demand, and strategic investments despite challenges like environmental regulations and market volatility. The industry's history shows a pattern of expansion post-WWII, peak production in the 1970s, followed by decline...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel production in the United States varies by state, reflecting unique resources, workforce skills, and industrial strategies; key states like Indiana, Pennsylvania, Texas, and Ohio lead due to factors such as natural resource availability and technological innovation. Mini-mills have revolutionized...

Steel production is a highly energy-intensive process with significant environmental impacts, making the understanding and monitoring of energy consumption at each stage crucial for sustainability. Energy efficiency in steel manufacturing is essential for cost-effectiveness, competitiveness, and reducing carbon emissions, with...

The global steel production landscape is a complex network essential for various industries, influenced by factors like raw material availability and technological advancements. China leads in output with other key players being India, Japan, and the US; sustainability efforts are...

Steel production is a fundamental aspect of Luxembourg's economy, driving innovation, job creation, and international trade while shaping the nation’s industrial landscape. The industry has evolved through technological advancements and sustainability efforts to maintain its relevance in the global market....

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

Steel was crucial in World War II, serving as the backbone for military equipment and influencing nations' industrial might. The escalation of steel production played a pivotal role in the Allied victory, with advancements in technology and massive job creation. Steel's...

China is the world's largest steel producer, with a focus on infrastructure and domestic industries driving substantial growth in its production capabilities. The country has shifted towards higher-value-added products, modernization, and global expansion through foreign investments to maintain dominance in...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...