Steel recycling

Steel recycling

Was ist Steel Recycling?

Steel recycling ist ein großer Teil der Stahlproduktion und des Stahlhandels. Es beschreibt den Prozess, bei dem alter Stahl und Stahlschrott gesammelt, verarbeitet und dann wieder zur Herstellung von neuem Stahl verwendet wird. Dieser Kreislaufprozess trägt zur Reduzierung der Umweltbelastung und zur Kosteneinsparung in der Stahlindustrie bei.

Warum ist Steel Recycling wichtig?

Das Recyceln von Stahl ist aus mehreren Gründen wichtig. Erstens trägt es zur Abfallreduzierung bei, da Stahlschrott einen erheblichen Anteil an den Industrieabfällen ausmacht. Zweitens spart es Ressourcen und Energie. Der Energieaufwand für die Verarbeitung von Stahlschrott zur Herstellung neuer Stahlprodukte ist deutlich geringer als der Energieaufwand für die Gewinnung von Eisenerz. Drittens trägt es zum Schutz der Umwelt bei. Mit dem Recycling von Stahl wird auch die Zahl der Abbaustätten für Eisenerz gesenkt.

Der Prozess des Steel Recyclings

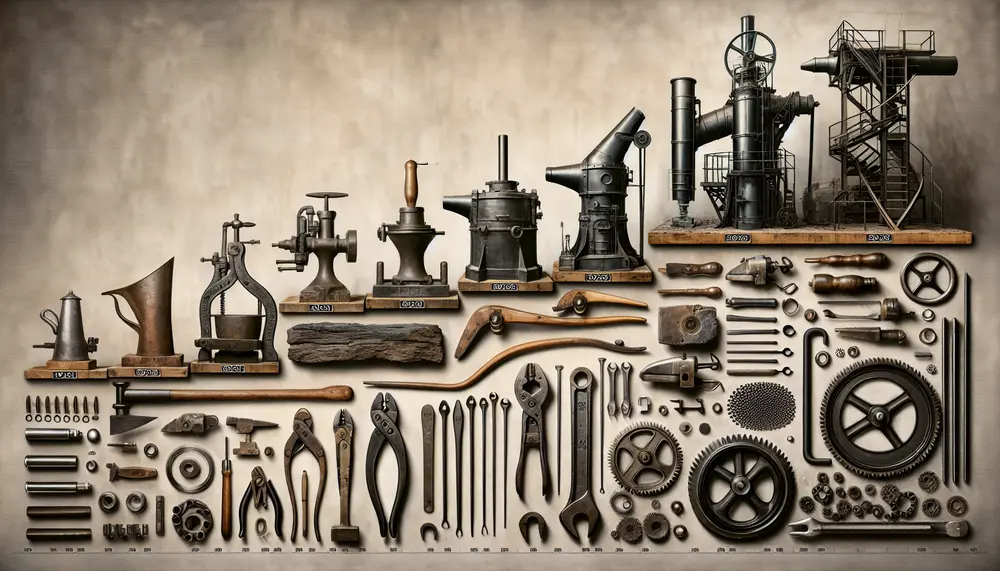

Der Prozess des Steel Recyclings besteht im Wesentlichen aus drei Schritten. Zu Anfang wird der Stahlschrott gesammelt und sortiert. Nach der Sortierung wird der Schrott zur Stahlschmelze transportiert. Dort wird er geschmolzen und in eine Form gebracht, die die Basis für neue Stahlprodukte bildet. Diese Produkte reichen von Baustahl bis hin zu Haushaltswaren.

Die Rolle des Steel Recyclings im Stahlhandel

Im Stahlhandel spielt Steel Recycling eine wichtige Rolle. Recycelter Stahl ist oft günstiger als neu produzierter Stahl. Dadurch kann der Handel mit recyceltem Stahl selbst in Zeiten niedriger Stahlpreise profitabel sein. Zudem spricht auch der ökologische Aspekt viele Unternehmen und Verbraucher an, wodurch die Nachfrage nach recyceltem Stahl steigt.

Blog Posts with the term: Steel recycling

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

Steel making technology has evolved from primitive forges to modern, efficient mills using methods like the Blast Furnace and Electric Arc Furnace (EAF), which recycles scrap metal. Recent innovations aim at enhancing efficiency and sustainability with developments such as advanced...

The article discusses various steelmaking furnace types, highlighting their unique characteristics and applications in the industry, emphasizing factors like efficiency, environmental impact, and suitability for different production needs....

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

Steelmaking has evolved from early iron manipulation to advanced processes like the Bessemer method, which revolutionized mass steel production and infrastructure development. Technological advancements such as open hearth furnaces and electric arc furnaces further refined steel's properties, while British dominance...

Vietnam's steel production industry is experiencing a resurgence, driven by significant investment in infrastructure and technology to meet both domestic demand and expand exports. The sector's growth reflects Vietnam's economic transformation, strategic vision for global market presence, commitment to sustainable...

Steelmaking is vital to modern civilization, driving economies, infrastructure development, and sustainability efforts. The industry relies on two main methods—Blast Furnace (BF) for large-scale production with higher emissions and Electric Arc Furnace (EAF) for flexibility and lower environmental impact—shaping a...

Steel production relies on a balance of raw materials like iron ore, coal, limestone, and scrap metal to determine the characteristics of different steel types. Understanding these ingredients is crucial for industry professionals as they influence strength, durability, and quality...

Steel making in Australia is crucial for the nation's infrastructure and economy, involving a two-stage process from iron ore to steel production using electric arc and basic oxygen furnaces. The industry has evolved over a century with technological advancements and...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

The article discusses the steel industry's transition from coal-based production to more sustainable methods due to climate change concerns, highlighting innovations like hydrogen use and renewable energy integration. It outlines both environmental impacts of traditional methods and pros and cons...

Steelmaking waste, primarily consisting of slag, dust, and sludges from iron and steel production processes, poses significant environmental risks such as groundwater contamination and ecosystem degradation if not managed properly. However, innovative recycling techniques like using slag in concrete or...