Vacuum Degassing

Vacuum Degassing

Einführung in Vacuum Degassing

Im Bereich der Stahlproduktion und des Stahlhandels ist Vacuum Degassing ein unverzichtbarer Prozess. Dabei handelt es sich um eine Methode, die dazu dient, unerwünschte Gase und Verunreinigungen aus flüssigem Stahl zu entfernen. Warum ist das wichtig? Weil diese Gase und Verunreinigungen die Qualität des Stahls beeinträchtigen können. Sie können zum Beispiel zu Poren und Brüchen im Endprodukt führen.

Wie funktioniert Vacuum Degassing?

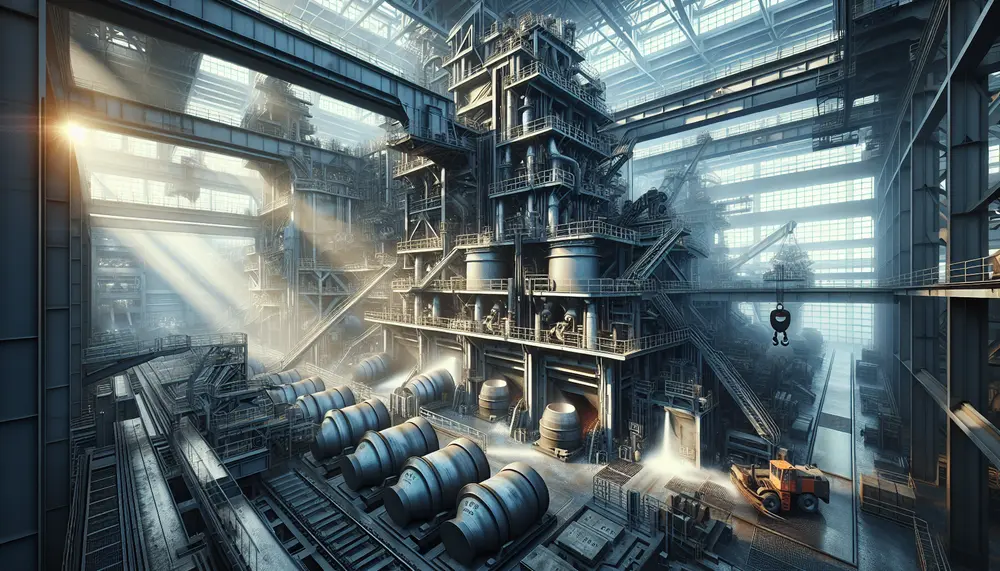

Die Methode des Vacuum Degassing wird normalerweise direkt nach dem Einschmelzen des Stahls und vor dessen Weiterverarbeitung durchgeführt. Der flüssige Stahl wird dabei in eine spezielle Kammer geleitet, in der ein Vakuum erzeugt wird. Durch den plötzlichen Druckabfall werden die unerwünschten Gase an die Oberfläche des flüssigen Metalls gebracht und können dort abgesaugt werden.

Die Vorteile von Vacuum Degassing

Das Verfahren des Vacuum Degassing hat zahlreiche Vorteile. Es verbessert die mechanischen Eigenschaften des Stahls, wie zum Beispiel seine Festigkeit und Duktilität. Darüber hinaus führt es zu einer gleichmäßigeren chemischen Zusammensetzung des Stahls und verhindert die Bildung von Gasblasen im Endprodukt. Das sorgt für einen höheren Qualitätsstandards und bessere Handelsmöglichkeiten.

Zukunft von Vacuum Degassing im Stahlhandel

Mit Blick auf die Zukunft, nimmt die Bedeutung des Vacuum Degassing im Stahlhandel weiter zu. Da die Anforderungen an die Qualität von Stahlprodukten steigen, sind saubere und gleichmäßige Produkte gefragt. Methoden wie das Vacuum Degassing tragen dazu bei, diesen steigenden Anforderungen gerecht zu werden.

Blog Posts with the term: Vacuum Degassing

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

RH technology, initially developed for hydrogen removal in steel making, now plays a crucial role in secondary refining and purification to ensure high-quality steel production. Key advancements like oxygen lances, powder injection systems, the RH-TOP system, and modern vacuum pumps...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

The article traces the evolution of steelmaking over nearly 4,000 years, highlighting key periods and innovations from ancient blacksmithing to modern techniques. It covers significant advancements such as Wootz steel in India, Chinese blast furnaces, medieval Damascus steel, and early...

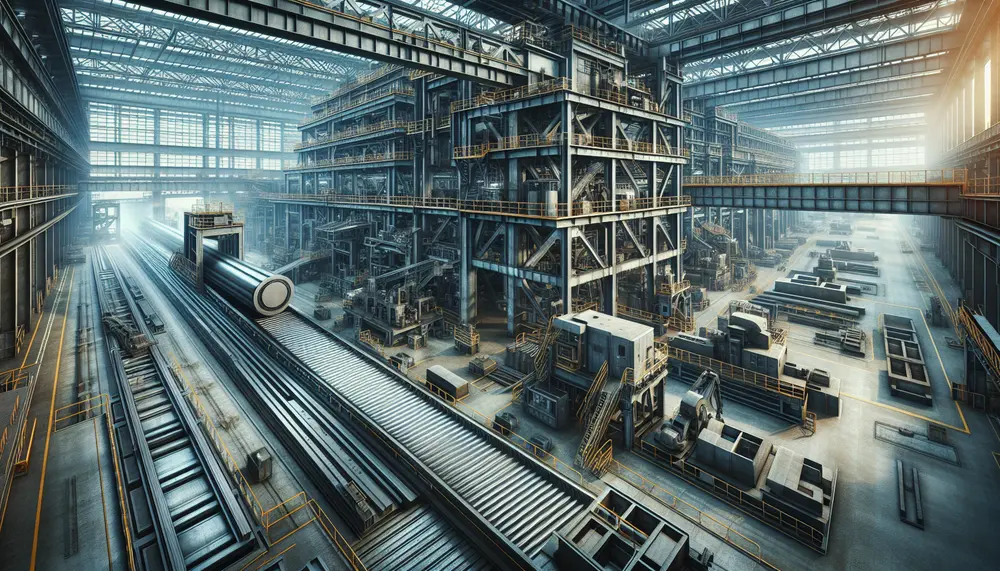

Steel production transforms raw materials like iron ore, coal, and limestone into steel through high-temperature processes in a factory. This complex journey from earth-bound elements to the final product is essential for construction and manufacturing industries, with each material playing...

Steel manufacturing is a complex, multi-stage process that transforms raw materials into the durable metal essential for modern infrastructure. It begins with extracting iron ore and progresses through various phases including blast furnace operation and primary steelmaking methods like Basic...

Steel making transforms iron ore into steel using blast furnaces or electric arc furnaces, involving processes like smelting and carbon adjustment to achieve desired properties. The production includes primary methods like Basic Oxygen Steelmaking and Electric Arc Furnace, followed by...

The Ladle Metallurgy Furnace (LMF) is a crucial advancement in modern steel production, allowing for precise control over the chemical composition and temperature of molten steel to produce high-quality products. This technology involves transferring liquid steel into a specialized furnace...

The steel making process at SAIL involves meticulous selection of raw materials and advanced technology in blast furnaces to produce molten iron, which is then refined using BOF or EAF methods. Rigorous quality control ensures the final product meets international...

The article emphasizes the importance of visually presenting the steel manufacturing process through engaging PowerPoint slides, breaking down complex steps like raw material preparation and blast furnace operations using diagrams, animations, and concise text to enhance understanding for diverse audiences....