Voltage

Voltage

Definition von Voltage

Voltage, auch bekannt als elektrische Spannung, ist ein grundlegender Begriff in der Elektrotechnik. Es definiert die Energie, die für den Transport elektrischer Ladungen erforderlich ist. Voltage ist besonders relevant in Verbindung mit der Stahlproduktion und dem Stahlhandel, da dieser Sektor stark auf Elektrizität angewiesen ist.

Voltage in der Stahlproduktion

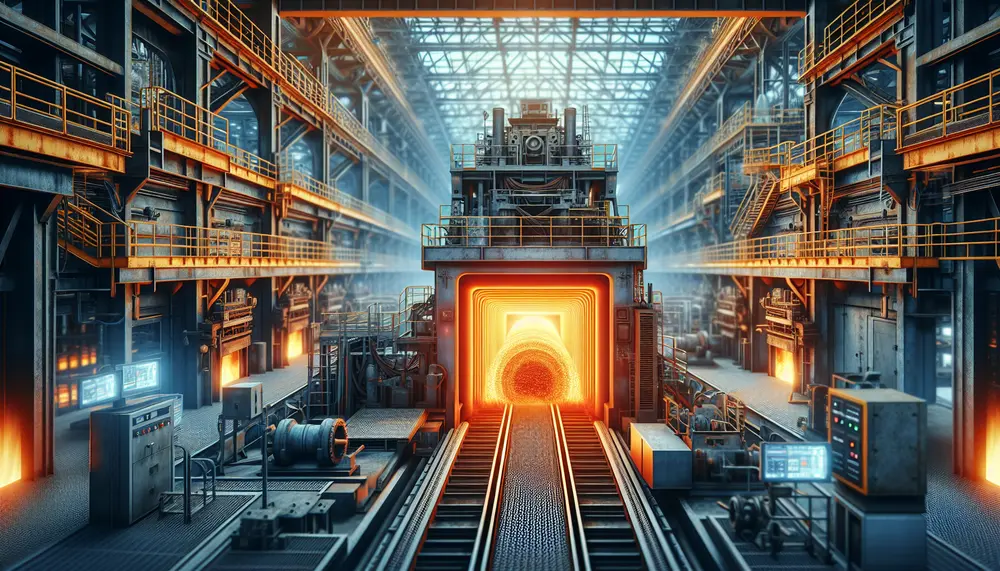

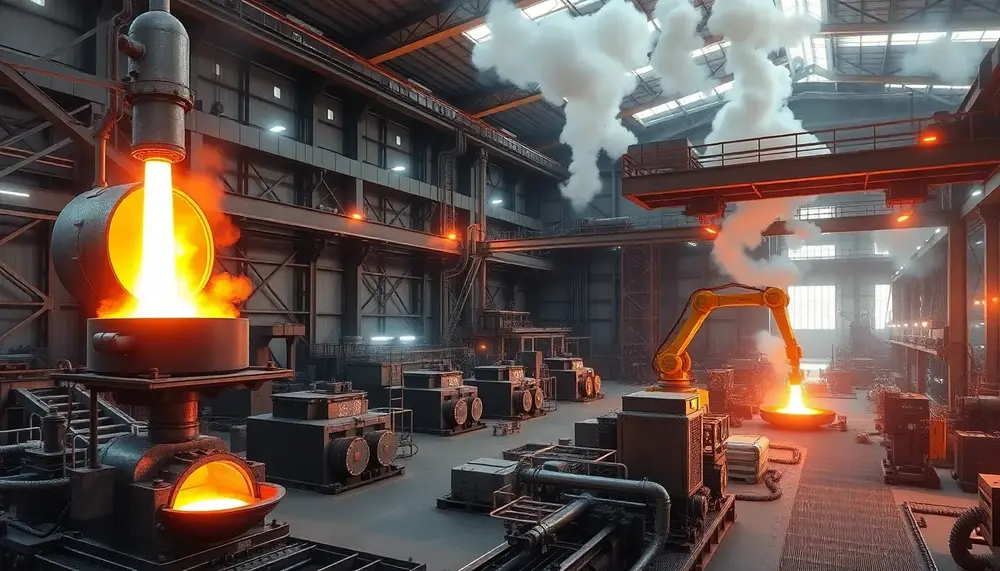

Die Rolle der Voltage in der Stahlproduktion ist nicht zu unterschätzen. Ohne angemessenen Spannung wäre der Prozess der Stahlproduktion, der viel Energie verbraucht, nicht möglich. Beispielsweise wird bei der elektrischen Lichtbogenofen-Methode - einer gängigen Methode zur Stahlerzeugung - Voltage verwendet, um einen Lichtbogen zwischen den Elektroden und dem Schrott zu erzeugen, der dann den Schrott schmilzt.

Voltage im Stahlhandel

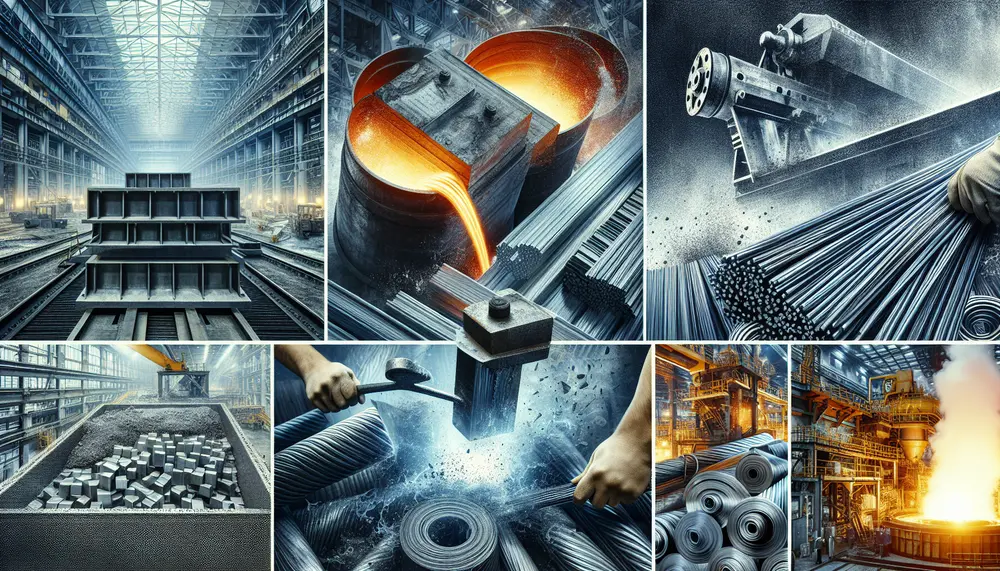

Auch im Stahlhandel ist Voltage ein wichtiges Element. Energieintensive Operationen wie z.B. das Heben und Transportieren von Stahl erfordern angemessene Spannung. Darüber hinaus wird Voltage benötigt, um Hochgeschwindigkeitsmaschinen für das Schneiden und Formen von Stahl anzutreiben.

Zusammenfassung

Kurz gesagt, Voltage ist ein entscheidender Faktor in der Stahlindustrie. Es erleichtert die energieintensiven Prozesse der Stahlproduktion und des Stahlhandels. Ohne den korrekten Einsatz von Voltage wäre die effiziente Produktion von Stahl nicht realisierbar.

Blog Posts with the term: Voltage

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

Steel making transforms iron ore into steel using blast furnaces or electric arc furnaces, involving processes like smelting and carbon adjustment to achieve desired properties. The production includes primary methods like Basic Oxygen Steelmaking and Electric Arc Furnace, followed by...

The article provides an in-depth look at modern steel production techniques, highlighting their importance and impact on various sectors including construction, transportation, appliances, and energy. It compares two primary methods - the Basic Oxygen Furnace (BOF) method which is faster...

Steel recycling transforms old materials into new products, conserving resources and energy while Electric Arc Furnaces (EAFs) enhance sustainable steel production through efficient scrap melting....

Steelmaking transforms iron into steel by increasing carbon content and refining the material through methods like blast furnaces and adding additives. Modern techniques include Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), focusing on sustainability, with raw materials such...

Steel's origins trace back to the use of iron by ancient civilizations and its transformation through smelting, leading to steel production once carbon content control was mastered. The evolution of steelmaking techniques has progressed from labor-intensive methods like the crucible...

The steel production casting process involves melting raw materials, refining the molten metal, and pouring it into molds to shape solid products with controlled cooling to prevent defects. The variety of cast steels is determined by carbon content and alloying...

The evolution of steelmaking in America reflects centuries of innovation, from colonial ironworks to modern high-tech factories, driven by technological breakthroughs and economic demands. Key milestones like the Bessemer process and basic oxygen furnaces revolutionized production efficiency, solidifying steel's role...

The steel making process begins with the extraction of raw materials, primarily iron ore and coke. The process involves smelting in a blast furnace to produce pig iron, which is then purified and mixed with alloying elements before being cast...