Wear resistance

Wear resistance

Was bedeutet Wear Resistance?

Das Konzept der Wear resistance oder Verschleißfestigkeit bezieht sich auf die Fähigkeit eines Materials, seine Form zu behalten und gegen Abnutzung, Reibung oder Materialverlust zu widerstehen. In der Stahlproduktion und im Stahlhandel ist dieser Begriff besonders wichtig, da die Verschleißfestigkeit einer Stahlsorte ein entscheidender Faktor für ihre Anwendung und Langlebigkeit ist.

Wie misst man die Wear Resistance?

Die Verschleißfestigkeit eines Materials misst man oft durch Tests, in denen die Fähigkeit eines Materials, seinen Charakter unter verschiedenen Belastungen zu behalten, gemessen wird. Bei Stahl beispielsweise kann dies durch Reibungstests, bei denen Stahl gegen ein abrasives Material gerieben wird, oder durch Ermüdungstests, in denen Stahl wiederholt Spannung und Ermüdung ausgesetzt ist, getestet werden.

Warum ist Wear Resistance im Stahlsektor wichtig?

In der Stahlerzeugung und dem Stahlhandel ist die Verschleißfestigkeit ein Schlüsselfaktor für die Qualität eines Stahlprodukts. Stahl mit hoher Verschleißfestigkeit behält seine Form und Funktion auch nach längerem Gebrauch oder unter schwierigen Bedingungen bei. Dies ist besonders wichtig in Industrien, wo Stahlteile viel Abnutzung ausgesetzt sind, wie z.B. in der Automobilindustrie, der Bauindustrie oder der Maschinenbauindustrie.

Welchen Einfluss hat die Wear Resistance auf den Stahlhandel?

Die Verschleißfestigkeit einer Stahlsorte kann ihren Wert auf dem Markt erheblich beeinflussen. Stahlarten mit hoher Verschleißfestigkeit sind oft teurer, da sie langlebiger sind und seltener ersetzt werden müssen. Daher kann eine hohe Verschleißfestigkeit ein entscheidendes Verkaufsargument für Kunden sein, die auf der Suche nach langlebigen, zuverlässigen Stahlprodukten sind.

Blog Posts with the term: Wear resistance

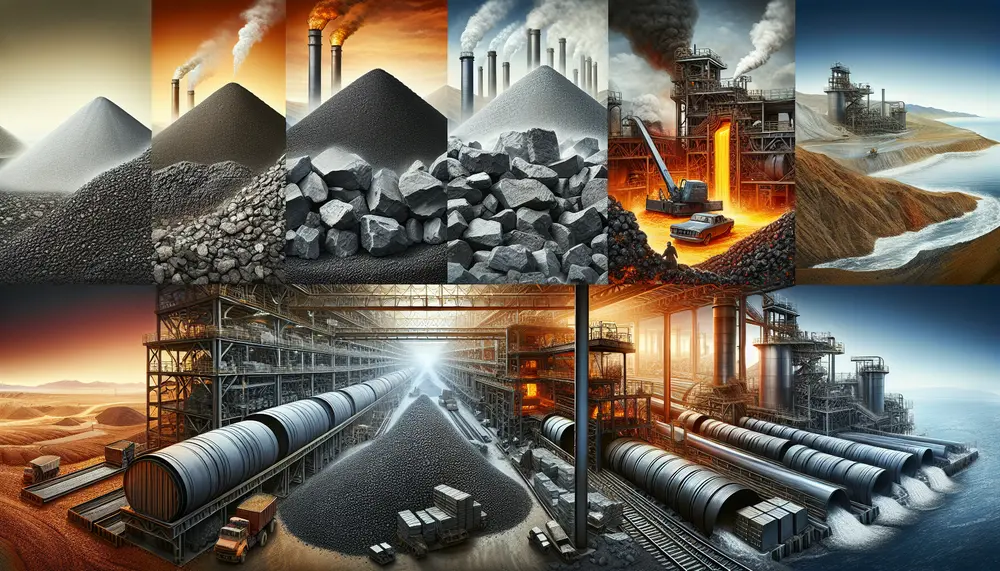

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel production relies on a balance of raw materials like iron ore, coal, limestone, and scrap metal to determine the characteristics of different steel types. Understanding these ingredients is crucial for industry professionals as they influence strength, durability, and quality...

Steel is an iron-carbon alloy with varying carbon content that determines its hardness, ductility, and tensile strength; other elements like chromium can be added to enhance specific properties such as corrosion resistance. Steel products are categorized into four main types:...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

The article explains the essential materials and processes involved in steel production, highlighting iron ore, carbon (coke), limestone, manganese, aluminum, and zinc as key components. It details how these elements are processed through smelting and alloying to enhance properties like...

Steel making transforms iron ore into steel using blast furnaces or electric arc furnaces, involving processes like smelting and carbon adjustment to achieve desired properties. The production includes primary methods like Basic Oxygen Steelmaking and Electric Arc Furnace, followed by...

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

The article emphasizes the importance of visually presenting the steel manufacturing process through engaging PowerPoint slides, breaking down complex steps like raw material preparation and blast furnace operations using diagrams, animations, and concise text to enhance understanding for diverse audiences....

Steelmaking slag, a by-product of steel production, can be repurposed for various applications such as construction and cement production due to its valuable properties like strength, durability, and chemical stability. This not only reduces industrial waste but also promotes environmental...