Width

Width

Was bedeutet 'Width' in der Stahlproduktion und im Stahlhandel?

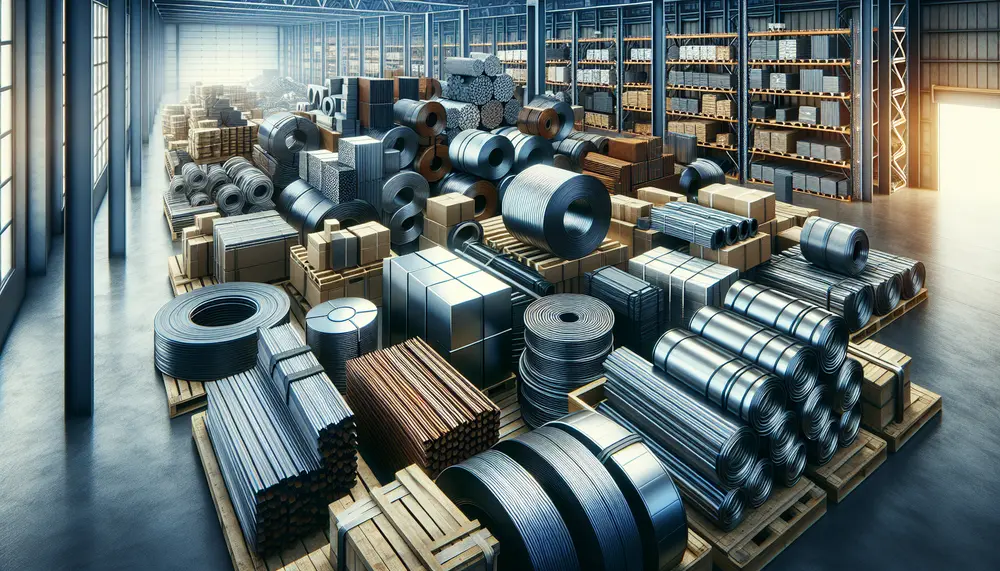

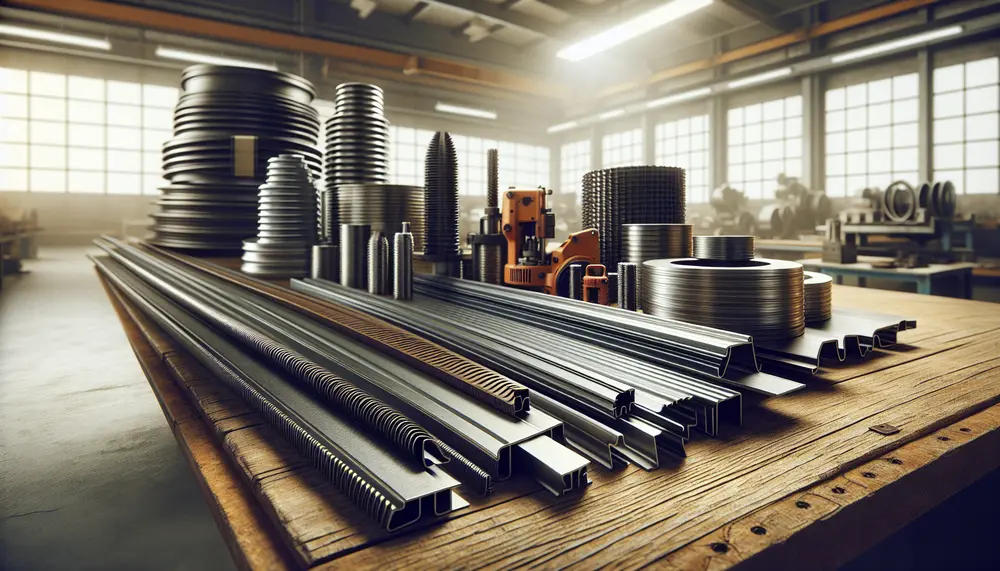

Das Wort Width wird im Kontext der Stahlproduktion und im Stahlhandel verwendet, um die Breite eines Stückes Stahl zu bezeichnen. Diese Breitenmessung ist ein äußerst wichtiger Faktor, wenn es um das Design und die Herstellung von Stahlerzeugnissen geht, da sie zum einen darüber entscheidet, wie viel Material benötigt wird und zum anderen beeinflusst, wie das Endprodukt aussehen wird.

Wie wird 'Width' in der Praxis genutzt?

In der Stahlindustrie sind genau definierte Width Messungen von großer Bedeutung. Sie stellen sicher, dass jedes Stück Stahl genau die richtige Größe hat, um in einem bestimmten Produkt verwendet zu werden. Hersteller legen oft sehr genaue Spezifikationen für die Breite des Stahls fest, den sie benötigen. Diese Messungen müssen daher streng eingehalten werden, um sicherzustellen, dass die Qualität und Leistung des Endprodukts nicht beeinträchtigt werden.

Warum ist 'Width' so wichtig?

Width ist von zentraler Bedeutung in der Stahlproduktion und im Stahlhandel, weil es die Benutzung von Stahlprodukten bestimmt. Es ist nicht nur von Bedeutung für das Design, sondern bestimmt auch die Stabilität eines Stahlproduktes. Ein Stahlträger mit einer Breite von 100 mm trägt zum Beispiel mehr Gewicht als ein Stahlträger von nur 50 mm Breite. Deshalb muss beim Handel mit Stahlprodukten stets die genaue Width angegeben werden.

Blog Posts with the term: Width

HTS codes are essential for classifying steel products in international trade, determining tariffs and compliance with regulations. They require precise understanding due to their complexity and frequent updates influenced by global trade changes....

Japanese steelmaking blends ancient traditions with modern innovations, producing some of the world's finest steel. This article explores its rich history from early Tatara furnaces to advanced techniques today, highlighting the craftsmanship and enduring legacy of Japanese steel production....

The POSCO steel making process is a sophisticated combination of technology and environmental care, producing high-quality steel through efficient, innovative methods like the FINEX technology. This multi-stage production includes ironmaking, refining in a basic oxygen furnace during the converter phase,...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

Steelmaking is a complex process involving several critical steps, from extracting iron to refining and shaping it into high-quality steel. Key stages include ironmaking, primary and secondary steelmaking, casting, forming, finishing, selecting appropriate materials like iron ore and coke, and...

Steel manufacturing transforms iron ore into steel through a series of processes, starting with smelting in blast furnaces and including primary and secondary steelmaking to adjust chemical composition and remove impurities. The final product is cast, formed, and carefully temperature-controlled...

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Flat steel products, including sheets, plates, and coils, are essential in industries like construction and automotive due to their versatility, strength, and cost-effectiveness; they undergo processes such as hot rolling for basic shaping and cold rolling for precision applications....

Steel production is a critical process that creates an alloy of iron and carbon, essential for various industries. It involves extracting iron ore, refining it into steel with specific carbon content through methods like basic oxygen steelmaking or electric arc...

Laser precision cutting is a key technology in steel manufacturing, offering high accuracy and the ability to create complex shapes with minimal waste. It combines speed, versatility, and CNC integration for consistent quality production while maintaining material integrity through reduced...

Steel weatherstripping is essential for sealing buildings and vehicles against air, water, dust, and pests; it's durable and energy-efficient. Proper installation and maintenance are crucial for its effectiveness in insulation and protection over time....