Posts on the Topic Innovations and technology in steelmaking

Vacuum Tank Degassing (VTD) revolutionizes steelmaking by delivering ultra-pure, high-performance steels with superior mechanical properties and process flexibility. Its adoption drives innovation across industries like automotive, energy, and medical devices while digital monitoring boosts efficiency and traceability....

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

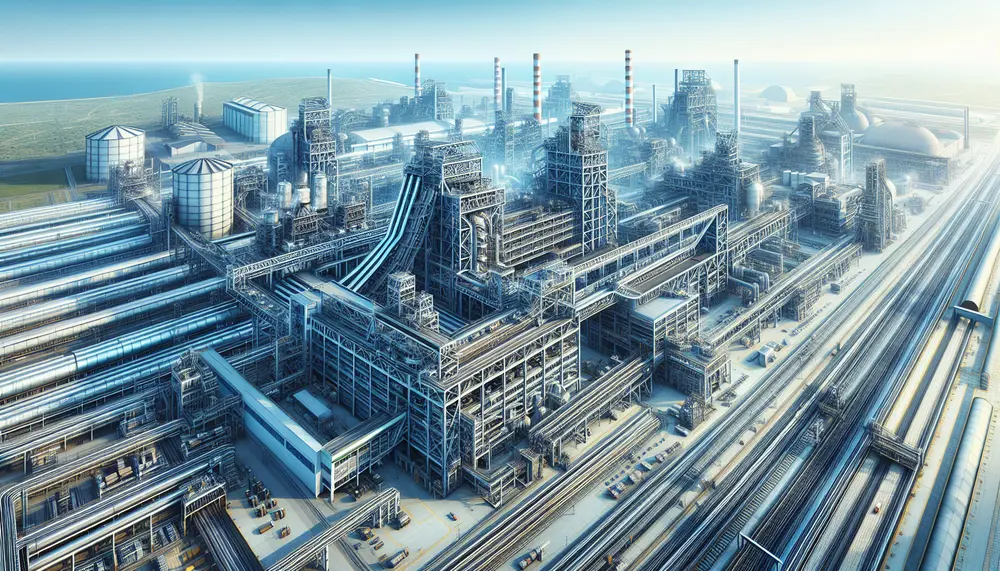

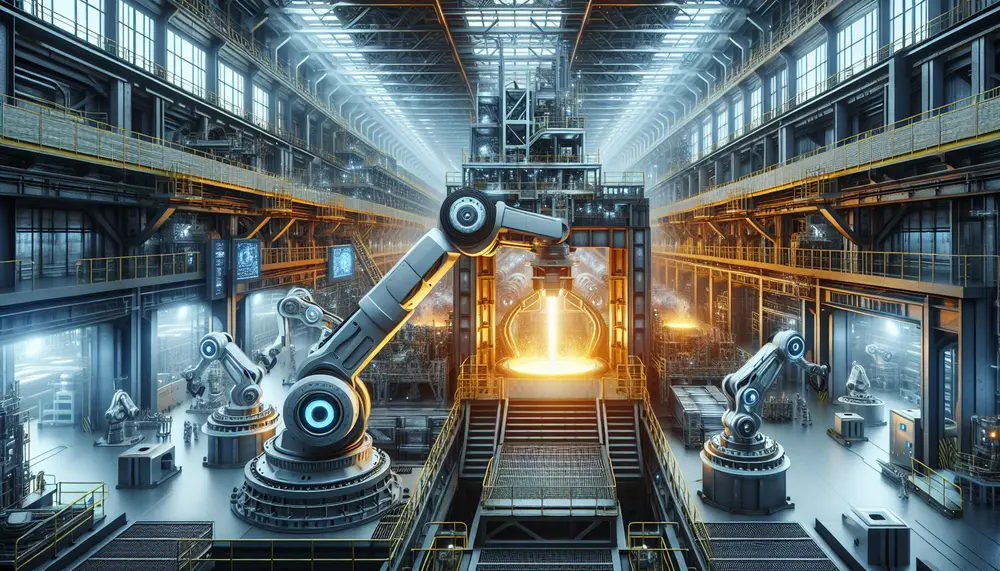

Danieli is revolutionizing steel production by integrating advanced, sustainable technologies like the Steel Plant Model and green solutions to enhance efficiency and reduce environmental impact. Their innovative approach combines adaptability, energy optimization, and emission reduction while setting new industry benchmarks...

Steelmaking R&D drives innovation by integrating sustainability, advanced technologies like hydrogen-based processes and AI modeling, and fostering breakthroughs in efficiency and emissions reduction. These advancements are reshaping industries reliant on steel while addressing global environmental challenges through cleaner production methods...

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

CFD steelmaking jobs are on the rise, offering a blend of technology and metallurgy to optimize processes in the steel industry through simulations that enhance efficiency and sustainability. Professionals in this field require technical proficiency, software expertise, analytical skills, problem-solving...

Steelmaking without coal, utilizing electricity and hydrogen from renewable sources, offers a sustainable alternative to traditional methods by reducing carbon emissions. The shift towards green steel production is driven by innovations like electric arc furnaces and low-carbon materials, with industry...

Steelmaking universities offer a blend of theoretical and practical education in metallurgical engineering, focusing on the science behind metal properties and production processes. Students learn through courses ranging from thermodynamics to advanced materials engineering, with hands-on experience in modern labs...

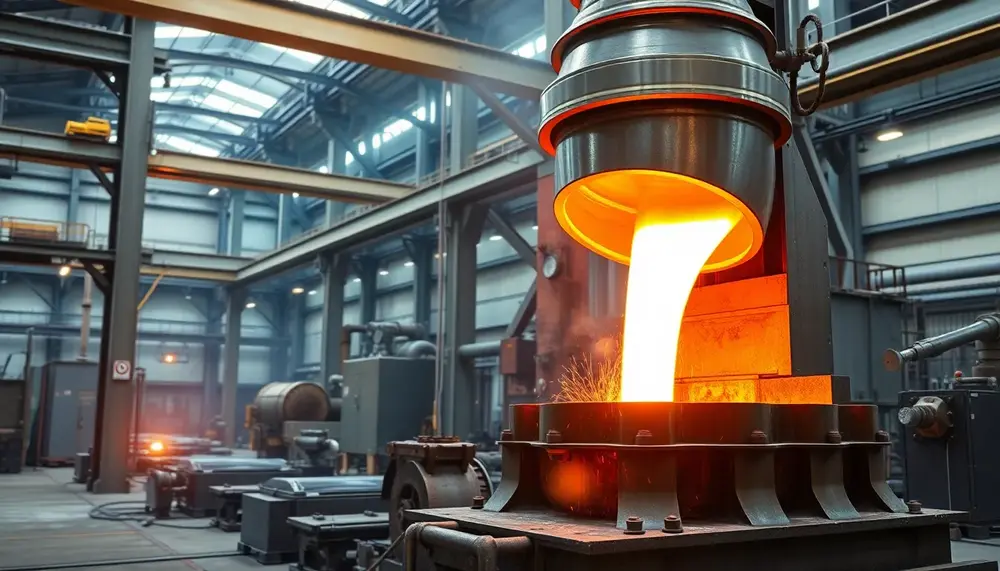

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

Steelmaking, particularly through traditional blast furnace methods, significantly contributes to environmental degradation by emitting greenhouse gases like CO2 and other pollutants. Transitioning to greener technologies such as Electric Arc Furnaces (EAF) could reduce these emissions but requires substantial investment and...

The AM/NS steel making process integrates traditional methods with advanced technology, emphasizing sustainability by using electric arc furnaces for recycling scrap metal and implementing strict emission controls. This approach reflects the industry's shift towards more efficient and environmentally responsible production,...

ArcelorMittal's steel making process combines traditional methods with advanced technologies, focusing on sustainability and efficiency. The company continuously innovates to improve quality and reduce environmental impact while maintaining a strategic approach to resource management in the global steel industry....

Steel product tools are essential in construction for their strength, precision, and safety contributions. They have evolved from manual to high-tech instruments, enhancing efficiency and sustainability in modern building practices. Using steel tools offers durability, accuracy, speed, worker safety, cost-efficiency, and...

Steel innovation, the development and implementation of new technologies in steel production, plays a crucial role in industrial progress by improving efficiency, quality and sustainability. Recent advancements include more efficient resource use and waste reduction, recycling processes for high-quality steel...

New steel making technologies are emerging to increase productivity, quality and reduce environmental damage. These include the Organic Rankine Cycle (ORC) Technology that generates electricity from waste heat, the Hydrogen Breakthrough Ironmaking Technology (HYBRIT Process) for carbon-free production, Jet Process...

Modern steel production faces challenges like volatile raw material prices, strict environmental standards, and the need for flexible processes; the Conarc process addresses these by combining BOF and EAF technologies to maximize efficiency, adaptability, and product quality....

Optimized EBT taphole filling mass and automated management enhance steel purity, operational reliability, safety, and productivity in modern steel plants....

Vacuum Tank Degassing (VTD) revolutionizes steelmaking by delivering ultra-pure, high-performance steels with superior mechanical properties and process flexibility. Its adoption drives innovation across industries like automotive, energy, and medical devices while digital monitoring boosts efficiency and traceability....

LTS steelmaking uses lower temperatures and advanced controls to cut emissions, boost efficiency, and enable flexible, cleaner regional steel production....

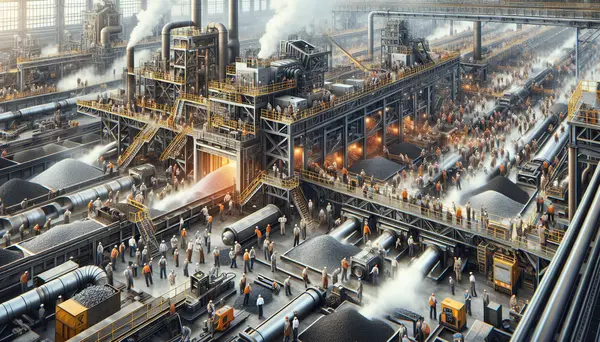

Innovative, data-driven research and advanced technologies are revolutionizing steelmaking by boosting efficiency, sustainability, and competitiveness across the industry....

Steelmakers face urgent pressure to decarbonize, making hydrogen-based steelmaking a strategic priority; key technologies like H-DR and electrolysis are compared for scalability, cost, and emissions....

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

Danieli is revolutionizing steel production by integrating advanced, sustainable technologies like the Steel Plant Model and green solutions to enhance efficiency and reduce environmental impact. Their innovative approach combines adaptability, energy optimization, and emission reduction while setting new industry benchmarks...

Steelmaking R&D drives innovation by integrating sustainability, advanced technologies like hydrogen-based processes and AI modeling, and fostering breakthroughs in efficiency and emissions reduction. These advancements are reshaping industries reliant on steel while addressing global environmental challenges through cleaner production methods...

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

The article discusses the transformative advancements in steel production, emphasizing innovations like hydrogen-based reduction and AI that enhance efficiency while reducing environmental impact....

Modern steelmaking is evolving with innovations like the OB furnace process and hydrogen integration, which enhance efficiency and sustainability by reducing carbon emissions while addressing cost challenges....

Hisarna steelmaking revolutionizes the industry by using innovative technology to produce steel with reduced energy and emissions, enhancing efficiency while offering significant environmental benefits....

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

CFD steelmaking jobs are on the rise, offering a blend of technology and metallurgy to optimize processes in the steel industry through simulations that enhance efficiency and sustainability. Professionals in this field require technical proficiency, software expertise, analytical skills, problem-solving...

Hydrogen steelmaking is revolutionizing the industry by using hydrogen instead of coal, significantly reducing carbon emissions and aligning with global climate goals while opening new economic opportunities....

Steelmaking without coal, utilizing electricity and hydrogen from renewable sources, offers a sustainable alternative to traditional methods by reducing carbon emissions. The shift towards green steel production is driven by innovations like electric arc furnaces and low-carbon materials, with industry...

Steelmaking universities offer a blend of theoretical and practical education in metallurgical engineering, focusing on the science behind metal properties and production processes. Students learn through courses ranging from thermodynamics to advanced materials engineering, with hands-on experience in modern labs...

The article discusses the dominant steelmaking companies that shape the global industry, their production methods, strategies for sustainability and innovation, and how they adapt to challenges. It highlights major players like China Baowu Group and ArcelorMittal as well as emerging...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

Steelmaking flux is crucial in producing high-quality steel, acting as a cleansing agent to remove impurities and enhance the metal's properties. Different types of fluxes are used for specific tasks during production, impacting impurity removal and refining processes while protecting...

Steelmaking, particularly through traditional blast furnace methods, significantly contributes to environmental degradation by emitting greenhouse gases like CO2 and other pollutants. Transitioning to greener technologies such as Electric Arc Furnaces (EAF) could reduce these emissions but requires substantial investment and...

The AM/NS steel making process integrates traditional methods with advanced technology, emphasizing sustainability by using electric arc furnaces for recycling scrap metal and implementing strict emission controls. This approach reflects the industry's shift towards more efficient and environmentally responsible production,...

ArcelorMittal's steel making process combines traditional methods with advanced technologies, focusing on sustainability and efficiency. The company continuously innovates to improve quality and reduce environmental impact while maintaining a strategic approach to resource management in the global steel industry....

Steel patina products offer a range of artistic and protective finishes for metalwork, allowing customization through various colors and textures. Understanding the properties of different patinas is crucial to achieving desired effects in both art and industrial applications, merging aesthetics...

Steel product tools are essential in construction for their strength, precision, and safety contributions. They have evolved from manual to high-tech instruments, enhancing efficiency and sustainability in modern building practices. Using steel tools offers durability, accuracy, speed, worker safety, cost-efficiency, and...

The steel industry is embracing innovative technologies for progress and sustainability, including Organic Rankine Cycle (ORC) technology that transforms waste heat into electricity, the Hybrit process which replaces coking coal with hydrogen in production, Jet Process to increase scrap usage,...

Steel, an alloy of iron and carbon, has been instrumental in shaping modern architecture due to its strength, durability and malleability. Its use dates back to the 1800s but it revolutionized architecture in the 20th century with large-span structures and...

Steel innovation, the development and implementation of new technologies in steel production, plays a crucial role in industrial progress by improving efficiency, quality and sustainability. Recent advancements include more efficient resource use and waste reduction, recycling processes for high-quality steel...

New steel making technologies are emerging to increase productivity, quality and reduce environmental damage. These include the Organic Rankine Cycle (ORC) Technology that generates electricity from waste heat, the Hydrogen Breakthrough Ironmaking Technology (HYBRIT Process) for carbon-free production, Jet Process...

Top 10 posts in the category

Unsere Beiträge zum Thema Innovations and technology in steelmaking

Delve into the dynamic world of steelmaking and discover the frontline of innovations and technology in steelmaking through our comprehensive articles. As the industry evolves, staying abreast of the latest technological advancements is crucial for professionals and enthusiasts alike. Our expertly curated content provides an in-depth look at the cutting-edge processes and ingenious solutions shaping the future of steel production.

By exploring our category, you'll gain valuable insights into the groundbreaking methods that are enhancing efficiency, sustainability, and cost-effectiveness in steel manufacturing. The benefits of understanding these innovations extend beyond professional knowledge; they are instrumental in recognizing emerging market trends and investment opportunities in the steel sector.

Our articles not only illuminate the technical aspects of innovations and technology in steelmaking but also emphasize their practical implications. Through expert analysis and case studies, you will learn about the transformative impact these technologies have on the industry’s landscape, allowing you to anticipate changes and adapt your strategies accordingly.

With every article, we aim to equip you with the knowledge to forge ahead in the competitive steel trade market. Embrace the opportunity to enhance your expertise and stay at the forefront of the industry with the valuable content provided under our 'Innovations and Technology in Steelmaking' category.