Posts on the Topic Production Processes

Secondary steelmaking refines and customizes steel after primary production, enabling precise control over composition and purity to meet modern industry demands. Key stages include deslagging, alloy addition, temperature adjustment, degassing, inclusion modification, and homogenization using advanced technologies like ladle furnaces...

Steelmaking is vital to modern civilization, driving economies, infrastructure development, and sustainability efforts. The industry relies on two main methods—Blast Furnace (BF) for large-scale production with higher emissions and Electric Arc Furnace (EAF) for flexibility and lower environmental impact—shaping a...

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

The article emphasizes the importance of visually presenting the steel manufacturing process through engaging PowerPoint slides, breaking down complex steps like raw material preparation and blast furnace operations using diagrams, animations, and concise text to enhance understanding for diverse audiences....

The article provides a detailed overview of the steelmaking process, highlighting key components like raw materials, energy sources, and advanced technologies. It explains primary methods (BOF and EAF), step-by-step production stages, and emphasizes sustainability and innovation in modern steel manufacturing....

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

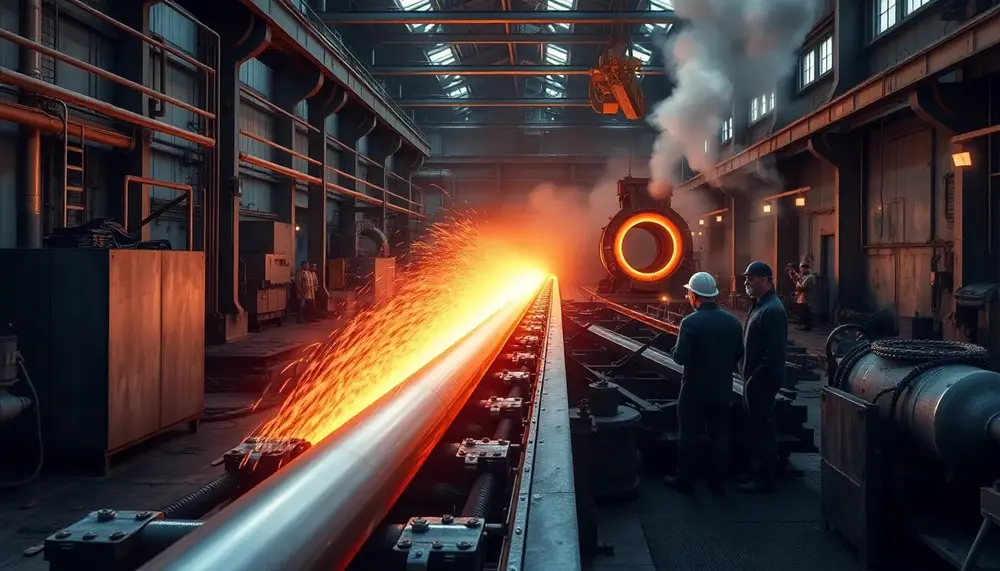

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

Steelmaking combines science and engineering to transform raw materials into tailored steel products through precise control of temperature, composition, and reactions. Its evolution reflects human innovation, from ancient smelting techniques to modern sustainable methods driven by advanced theoretical principles like...

Nucor revolutionizes steelmaking with its Electric Arc Furnace (EAF) process, transforming recycled scrap into high-quality steel while prioritizing sustainability and efficiency. This innovative approach reduces carbon emissions, enhances energy efficiency, and offers tailored solutions for industries like automotive and construction....

Steel manufacturing transforms raw materials like iron ore into robust steel products through a complex process involving chemistry, physics, and engineering. This journey from ancient methods to modern techniques includes steps such as blast furnace operations and refining processes, highlighting...

The article analyzes global steel production trends in 2023, highlighting regional differences and challenges such as supply chain disruptions. It examines the contrasting growth patterns across continents like Africa's rise due to infrastructure investments and Asia's decline influenced by China's...

The reduction ratio in steel making is crucial for optimizing efficiency, cost-effectiveness, and quality by determining the mechanical properties of steel through factors like temperature and impurities. Modern advancements have shifted from traditional ratios to more efficient ones, reflecting innovation...

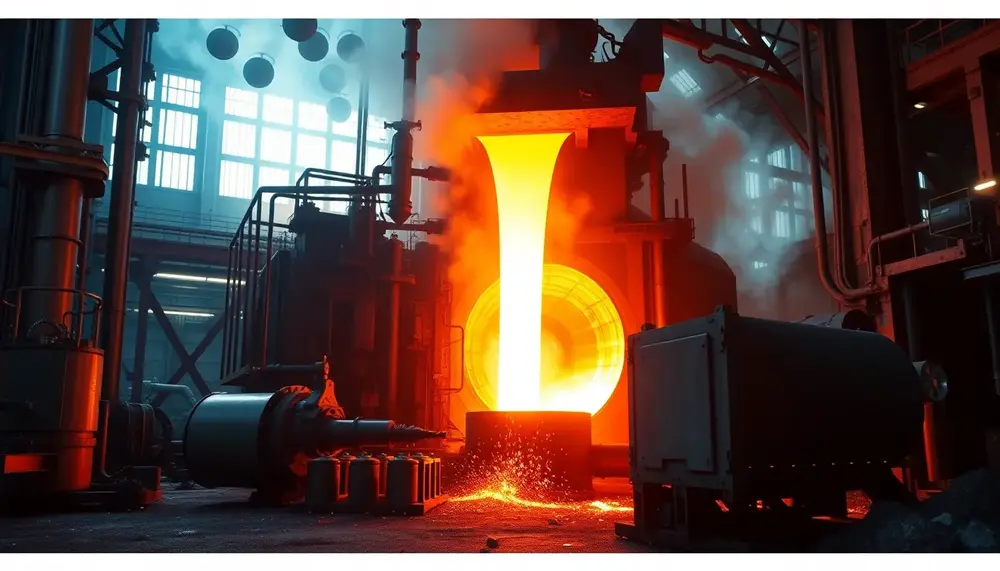

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

Steel recycling is a detailed process involving collection, sorting, shredding, melting, purification, and casting of scrap steel into new products; it offers significant environmental benefits like energy conservation and CO2 reduction while also providing economic advantages such as job creation...

The US steel industry has evolved from traditional methods to sustainable practices, focusing on recycling and technological innovation, with key players like Cleveland-Cliffs and Nucor leading advancements. Despite challenges such as international competition and environmental regulations, the industry remains a...

The green steelmaking process aims to reduce the significant CO₂ emissions from traditional steel production by utilizing cleaner technologies and renewable energy sources, including hydrogen. This transition involves optimizing existing processes, adopting new sustainable methods, and fully integrating green hydrogen...

The article explores the rich history of steelmaking, from ancient techniques like crucible and blast furnace methods to medieval advancements such as pattern welding, culminating in transformative innovations during the Industrial Revolution with processes like Bessemer and open-hearth furnaces. These...

The Argon Oxygen Decarburization (AOD) process is essential in producing high-quality stainless steel by refining molten steel to reduce carbon content while preserving valuable alloying elements like chromium. This method, involving precise control of gas mixtures and temperatures during decarburization,...

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

Hydrogen is revolutionizing steel production by serving as a cleaner reducing agent, enabling the industry to reduce carbon emissions and align with sustainability goals. However, integrating hydrogen technology faces challenges such as infrastructure overhaul, storage and transportation logistics, economic factors,...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The POSCO steel making process is a sophisticated combination of technology and environmental care, producing high-quality steel through efficient, innovative methods like the FINEX technology. This multi-stage production includes ironmaking, refining in a basic oxygen furnace during the converter phase,...

The article discusses the significance of names in steel manufacturing processes, which often reflect their inventors, locations, or characteristics and serve as a historical timeline of industry advancements. It also outlines how terminology has evolved with technology and globalization, providing...

Steel production is essential to modern industry but generates significant emissions, with the traditional Blast Furnace-Basic Oxygen Furnace (BF-BOF) method being particularly carbon-intensive. Innovative strategies like smart manufacturing and alternative energy sources are being adopted to reduce these environmental impacts,...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Secondary steelmaking refines and customizes steel after primary production, enabling precise control over composition and purity to meet modern industry demands. Key stages include deslagging, alloy addition, temperature adjustment, degassing, inclusion modification, and homogenization using advanced technologies like ladle furnaces...

Steelmaking is evolving with integrated and electric arc furnace routes, digital monitoring, and circular economy practices driving efficiency, but full integration remains a challenge....

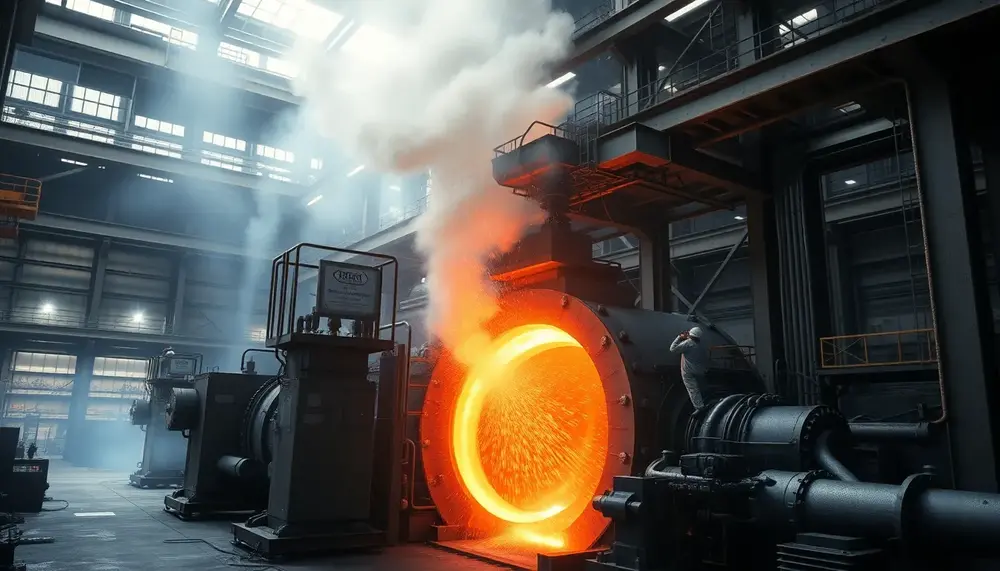

Upsetting in steel processing is a precise technique that thickens specific areas by axial compression, enhancing strength and durability through controlled heat and deformation....

Stainless steel manufacturing is a precise, multi-stage process combining advanced technology and strict quality control to produce durable, corrosion-resistant materials....

Steel wire manufacturing requires high-quality rods, advanced drawing machines, precise heat treatment, and meticulous preparation to ensure strong, defect-free wires....

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Maximizing steel output relies on optimizing process variables, strategic raw material management, and advanced automation for smarter, more efficient production....

In 2022, global crude steel production saw a shift as regions balanced traditional BOF methods with growing EAF adoption driven by sustainability and local factors....

Animated GIFs simplify complex steelmaking processes by visually breaking down each step, making technical concepts accessible and memorable for all audiences....

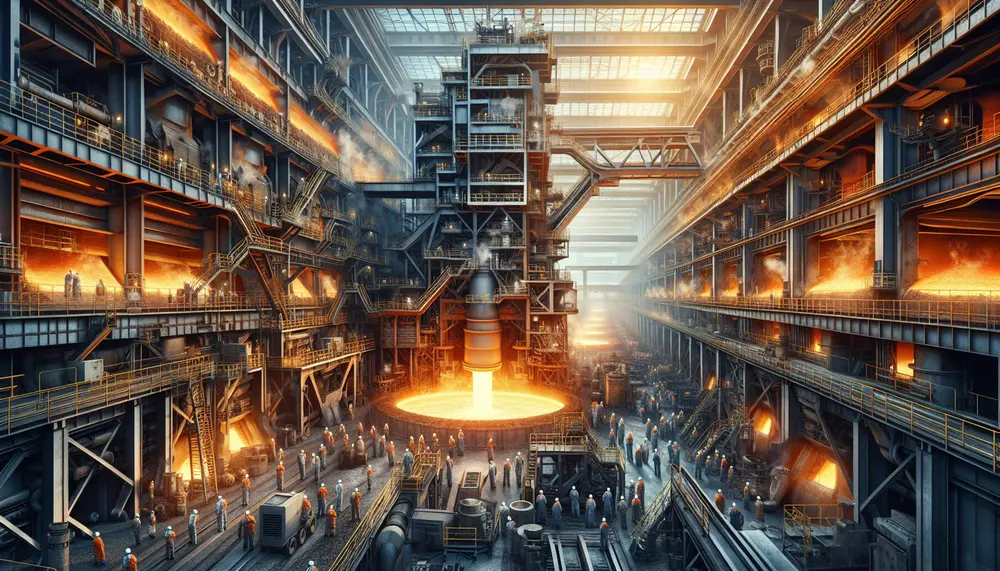

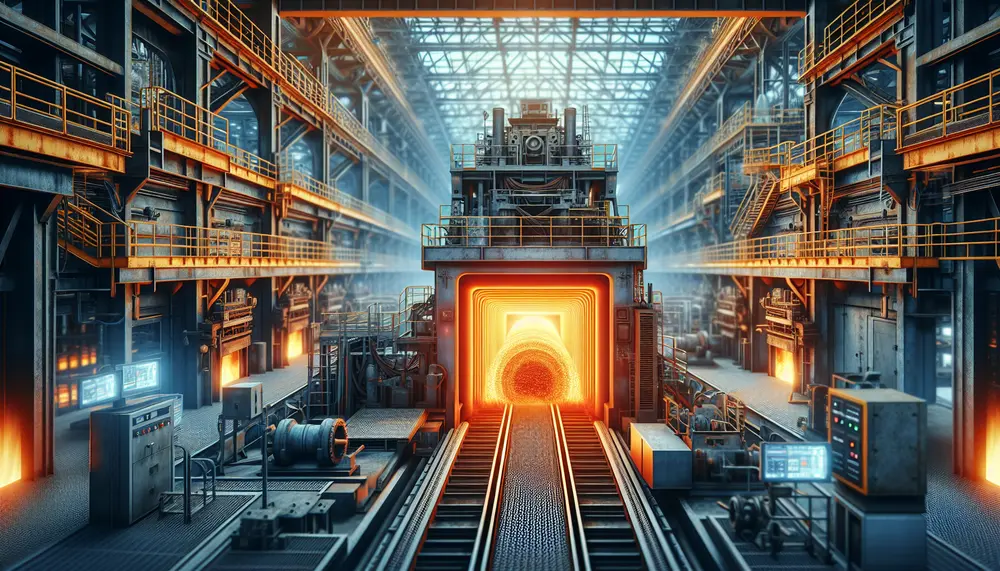

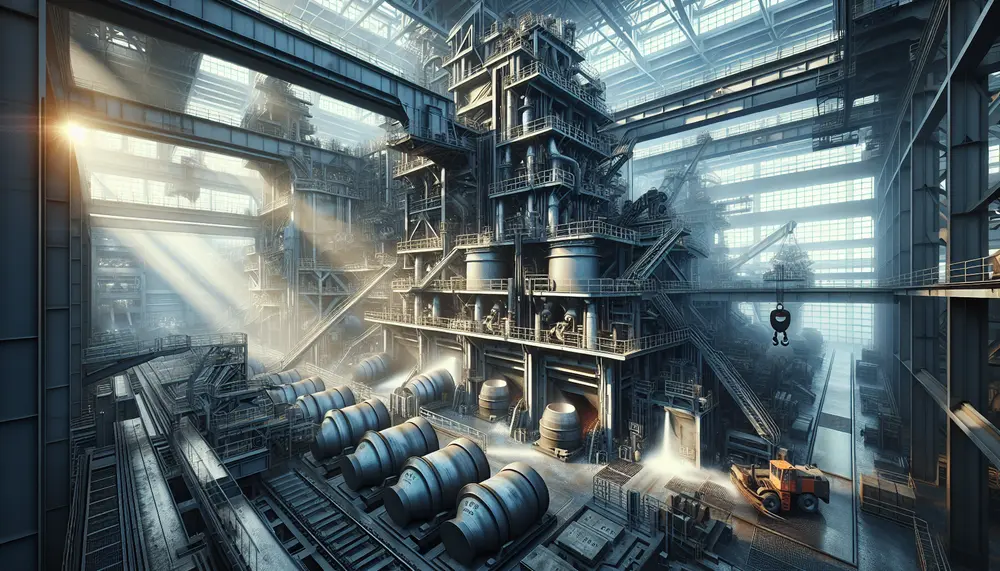

Modern steel factories combine advanced technology, automation, and strict quality control to transform raw materials into high-quality steel with precision and efficiency....

Steelmaking is vital to modern civilization, driving economies, infrastructure development, and sustainability efforts. The industry relies on two main methods—Blast Furnace (BF) for large-scale production with higher emissions and Electric Arc Furnace (EAF) for flexibility and lower environmental impact—shaping a...

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

Task 1 in steel rod manufacturing, the preparation of raw materials like iron ore, yellow ore, and carbon, is crucial for ensuring product quality and consistency. This stage requires precision in material selection, ratios, and mixing techniques to set a...

The article emphasizes the importance of visually presenting the steel manufacturing process through engaging PowerPoint slides, breaking down complex steps like raw material preparation and blast furnace operations using diagrams, animations, and concise text to enhance understanding for diverse audiences....

The article provides a detailed overview of the steelmaking process, highlighting key components like raw materials, energy sources, and advanced technologies. It explains primary methods (BOF and EAF), step-by-step production stages, and emphasizes sustainability and innovation in modern steel manufacturing....

Brazing cast iron to steel is a challenging process due to their differing thermal behaviors, requiring precise preparation, the right filler material like bronze, and proper use of flux. Success depends on careful cleaning, gradual preheating, and maintaining controlled temperatures...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

Process gases like blast furnace gas, coke gas, and converter gas play a crucial role in steel manufacturing by enhancing energy efficiency, reducing costs, and supporting sustainability. These gases are repurposed for power generation, industrial processes, and emission reduction efforts...

Steelmaking combines science and engineering to transform raw materials into tailored steel products through precise control of temperature, composition, and reactions. Its evolution reflects human innovation, from ancient smelting techniques to modern sustainable methods driven by advanced theoretical principles like...

Steelmaking transforms raw materials like iron ore, coal, and limestone into steel using methods such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF), with modern technologies enhancing efficiency and sustainability while addressing environmental concerns....

Nucor revolutionizes steelmaking with its Electric Arc Furnace (EAF) process, transforming recycled scrap into high-quality steel while prioritizing sustainability and efficiency. This innovative approach reduces carbon emissions, enhances energy efficiency, and offers tailored solutions for industries like automotive and construction....

Steel production is a complex process that transforms raw materials like iron ore, limestone, and coke into steel through stages such as iron making in blast furnaces, primary and secondary steelmaking for purification and customization, casting to form solid shapes,...

The article explores the historical and cultural significance of steel making, detailing ancient techniques like crucible steel production and emphasizing the importance of mastering carbon interaction in crafting high-quality steel....

Steel is a versatile and crucial industrial material made from iron, carbon, and other elements; its production involves processes like primary steelmaking (BOF and EAF) and secondary refining to achieve desired properties for various applications....

The manufacturing of steel almirahs involves a blend of art and science, utilizing precision machinery like lathes, drills, milling machines, and section bending tools to transform raw steel sheets into intricately designed and functional furniture pieces....

Steel nail production is a complex process involving the transformation of raw steel into durable nails, with innovations in design and materials enhancing their functionality for various applications....

Steel manufacturing transforms raw materials like iron ore into robust steel products through a complex process involving chemistry, physics, and engineering. This journey from ancient methods to modern techniques includes steps such as blast furnace operations and refining processes, highlighting...

Steelmaking involves transforming iron ore, along with materials like limestone and coke, into steel through complex processes in blast furnaces; the quality of these raw materials is crucial for producing strong and durable steel. Different types of iron ores such...

Rebar, a steel reinforcement bar used in concrete and masonry structures, enhances tensile strength to prevent cracking and structural failure; its various types cater to specific environmental needs while ensuring durability, safety, and cost-effectiveness in construction projects....

Tapping in steel making is a crucial process that impacts the quality and efficiency of production, with advancements like automation and predictive analytics enhancing precision, reducing waste, and improving energy use....

Steel recycling transforms old materials into new products, conserving resources and energy while Electric Arc Furnaces (EAFs) enhance sustainable steel production through efficient scrap melting....

The article analyzes global steel production trends in 2023, highlighting regional differences and challenges such as supply chain disruptions. It examines the contrasting growth patterns across continents like Africa's rise due to infrastructure investments and Asia's decline influenced by China's...

The reduction ratio in steel making is crucial for optimizing efficiency, cost-effectiveness, and quality by determining the mechanical properties of steel through factors like temperature and impurities. Modern advancements have shifted from traditional ratios to more efficient ones, reflecting innovation...

The steel making converter process is crucial for transforming raw materials into high-quality steel, accounting for 70% of global production through efficient and sustainable methods involving oxygen blowing to remove impurities....

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

Steel making efficiency is crucial for competitiveness and sustainability, involving optimization of energy use, material utilization, process streamlining, technology integration, and recycling to reduce costs and environmental impact....

Steel recycling is a detailed process involving collection, sorting, shredding, melting, purification, and casting of scrap steel into new products; it offers significant environmental benefits like energy conservation and CO2 reduction while also providing economic advantages such as job creation...

Lime is crucial in steelmaking, acting as a flux to remove impurities like phosphorus and sulfur, enhancing the quality of steel produced through processes such as EAF and BOF while also contributing to environmental sustainability by reducing emissions....

Heat is essential in steelmaking, driving chemical reactions and refining processes in methods like Basic Oxygen Furnaces (BOF) and Electric Arc Furnaces (EAF), with innovations focusing on energy efficiency and sustainability through advanced heat management techniques....

Flat steel products, including sheets, plates, and coils, are essential in industries like construction and automotive due to their versatility, strength, and cost-effectiveness; they undergo processes such as hot rolling for basic shaping and cold rolling for precision applications....

Steel making dies are essential tools in the manufacturing process, shaping steel with precision and consistency to meet industry demands; innovations like CAD/CAM systems have further enhanced their efficiency and quality....

The Electric Arc Furnace (EAF) is revolutionizing steelmaking by using electricity to melt scrap metal, reducing carbon emissions and supporting recycling efforts in a circular economy....

The VAD steelmaking process, or Vacuum Arc Degassing, is crucial for producing high-quality steel by removing impurities and gases like hydrogen and nitrogen through a vacuum environment, resulting in purer and more homogeneous steel with enhanced mechanical properties....

The US steel industry has evolved from traditional methods to sustainable practices, focusing on recycling and technological innovation, with key players like Cleveland-Cliffs and Nucor leading advancements. Despite challenges such as international competition and environmental regulations, the industry remains a...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article traces the evolution of steelmaking over nearly 4,000 years, highlighting key periods and innovations from ancient blacksmithing to modern techniques. It covers significant advancements such as Wootz steel in India, Chinese blast furnaces, medieval Damascus steel, and early...

The green steelmaking process aims to reduce the significant CO₂ emissions from traditional steel production by utilizing cleaner technologies and renewable energy sources, including hydrogen. This transition involves optimizing existing processes, adopting new sustainable methods, and fully integrating green hydrogen...

The steel making lance is a crucial tool in the steel production process, used to introduce gases like oxygen into molten metal for refining and impurity removal. Different types of lances serve specific purposes such as reducing carbon content or...

Understanding the gas composition in steelmaking is crucial for optimizing efficiency and reducing environmental impact. Key gases produced include Blast Furnace Gas, Coke Oven Gas, and Basic Oxygen Furnace Gas, each with unique compositions that can be harnessed for energy...

The article explores the rich history of steelmaking, from ancient techniques like crucible and blast furnace methods to medieval advancements such as pattern welding, culminating in transformative innovations during the Industrial Revolution with processes like Bessemer and open-hearth furnaces. These...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

The Argon Oxygen Decarburization (AOD) process is essential in producing high-quality stainless steel by refining molten steel to reduce carbon content while preserving valuable alloying elements like chromium. This method, involving precise control of gas mixtures and temperatures during decarburization,...

The Basic Oxygen Furnace (BOF) process, developed in the mid-20th century by Robert Durrer, revolutionized steel production by using pure oxygen to convert molten iron into high-quality steel efficiently. This method involves charging a furnace with molten iron and scrap...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Ironmaking and steelmaking are interdependent processes where iron ore is first transformed into molten pig iron in a blast furnace, then refined to create steel using either basic oxygen steelmaking (BOS) or electric arc furnaces (EAF). The evolution of these...

The article details the steel shot manufacturing process, from melting high-quality steel and atomizing it into droplets to cooling, sorting by size, heat treating for hardness and elasticity, conditioning for shape uniformity, tempering for toughness, rigorous testing for quality assurance...

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

Hydrogen is revolutionizing steel production by serving as a cleaner reducing agent, enabling the industry to reduce carbon emissions and align with sustainability goals. However, integrating hydrogen technology faces challenges such as infrastructure overhaul, storage and transportation logistics, economic factors,...

Oxygen plays a crucial role in steelmaking by reacting with carbon to reduce its content, thus transforming pig iron into high-quality steel and removing impurities like sulfur and phosphorus. The Basic Oxygen Steelmaking (BOS) process uses oxygen to accelerate reactions,...

Steel making is a complex process that refines raw materials into steel, involving steps like removing impurities and adding alloying elements. Modern methods include Basic Oxygen Steelmaking (BOF) and Electric Arc Furnace (EAF), with advancements in continuous casting and technology...

Steel slag, a byproduct of steel production with significant potential for various industries, is economically and environmentally important due to cost savings and reduced carbon footprint through recycling. It can be processed into materials comparable or superior to conventional raw...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The steel making process at SAIL involves meticulous selection of raw materials and advanced technology in blast furnaces to produce molten iron, which is then refined using BOF or EAF methods. Rigorous quality control ensures the final product meets international...

The POSCO steel making process is a sophisticated combination of technology and environmental care, producing high-quality steel through efficient, innovative methods like the FINEX technology. This multi-stage production includes ironmaking, refining in a basic oxygen furnace during the converter phase,...

The article explains the steel making process at SAIL Bokaro, highlighting its precision and adherence to quality and environmental standards. It details the journey from raw materials like iron ore, coal, and limestone through various stages including blast furnaces and...

The Electric Arc Furnace (EAF) method is a sustainable and efficient steel production technique that uses recycled scrap metal, offering environmental benefits such as reduced CO2 emissions while also being adaptable to market demands. However, it has drawbacks like high...

The steel making process is a complex series of steps transforming iron ore and coal into steel, involving stages like melting, refining, and casting. NPTEL provides comprehensive online education on this process through structured courses that offer both theoretical knowledge...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

Coke is crucial in steel production, providing heat and chemical reactions for smelting iron ore while also structuring the blast furnace. However, its use emits pollutants and CO2, contributing to environmental concerns....

The article discusses the significance of names in steel manufacturing processes, which often reflect their inventors, locations, or characteristics and serve as a historical timeline of industry advancements. It also outlines how terminology has evolved with technology and globalization, providing...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The steel production casting process involves melting raw materials, refining the molten metal, and pouring it into molds to shape solid products with controlled cooling to prevent defects. The variety of cast steels is determined by carbon content and alloying...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

Steel production is essential to modern industry but generates significant emissions, with the traditional Blast Furnace-Basic Oxygen Furnace (BF-BOF) method being particularly carbon-intensive. Innovative strategies like smart manufacturing and alternative energy sources are being adopted to reduce these environmental impacts,...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

The steel making process transforms iron ore into a vital and robust material through complex technical procedures, reflecting human ingenuity and progress. This journey from extraction to the final product involves meticulous steps including smelting in blast furnaces, oxidation for...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Top 10 posts in the category

Unsere Beiträge zum Thema Production Processes

Welcome to our comprehensive resource focusing on Production Processes in the steel industry. On this page, you will delve into the fascinating world of steel production, exploring a range of topics that cover the cutting-edge techniques and technologies that are shaping the future of steel manufacturing. Our expertly crafted articles offer deep insights into the various methods employed in the creation of steel, from traditional blast furnaces to innovative electric arc furnaces and beyond.

Dive into the intricate details of Production Processes such as basic oxygen steelmaking, direct reduced iron (DRI), and secondary refining. Understand the crucial steps that determine the quality, strength, and durability of the final product, which are essential for industries reliant on high-grade steel. By reading these articles, you stand to gain valuable knowledge that can influence purchasing decisions, provide a competitive edge in the steel trade market, and even spark ideas for efficiency improvements in related business sectors.

As you navigate through our carefully curated content, you will also learn about the environmental aspects of Production Processes. Discover the initiatives and advancements that are leading the way in reducing emissions and energy consumption in steel production. This is essential information for staying informed about sustainability practices and regulations in the industry.

Whether you are a professional in the steel trade, a student of metallurgy, or simply someone with an interest in industrial processes, our articles on Production Processes offer a wealth of knowledge that can enhance your understanding and appreciation of steel production. Stay informed, make more informed decisions, and keep abreast of technological progress by exploring our in-depth articles on steel production processes.