Posts on the Topic Steel production

Steel production in Kuwait has been steadily ascending, reflecting the nation's commitment to diversifying its economic sectors beyond the traditional oil industry. This growth is attributed to several factors, from government initiatives to the establishment of advanced industrial zones, positioning...

In the wake of dynamic economic transformation, Vietnam's steel production industry is flourishing, marking an impressive comeback after facing numerous challenges. An era of burgeoning development has been sparked, characterized by significant investment in infrastructure and technology, which in turn...

Forecasting steel production involves predicting the future output of steel, a critical material for countless industries worldwide. This process requires an in-depth analysis of various economic indicators, market trends, and geopolitical factors. Forecasts are not only essential for steel producers...

South Korea's role in the global steel market cannot be overstated. As a major player, the country has established itself...

The recent surge in steel production growth is a multifaceted phenomenon, reflecting a confluence of economic, technological, and strategic factors....

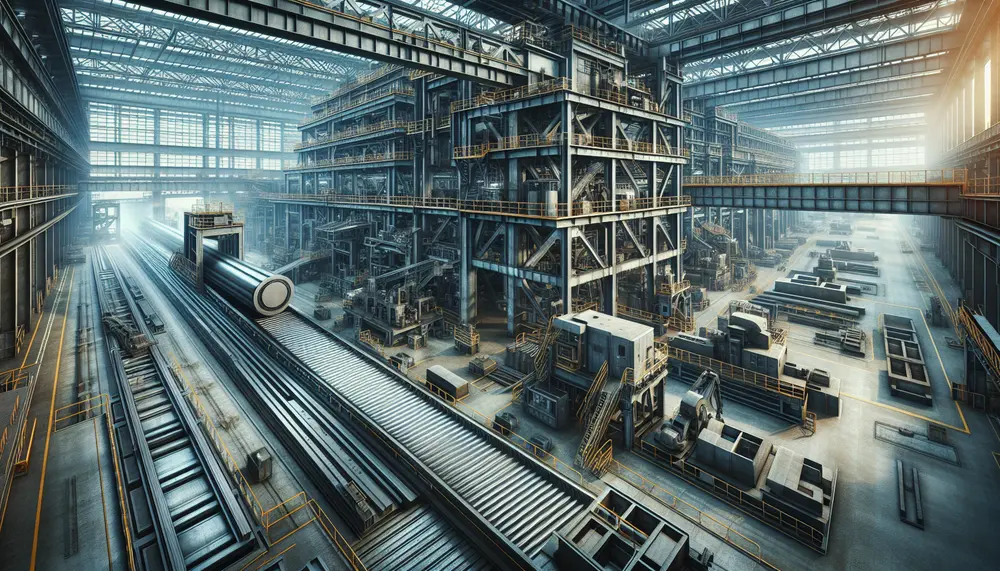

The steel manufacturing process is a cornerstone of industrial development, serving as the backbone for a broad array of infrastructural...

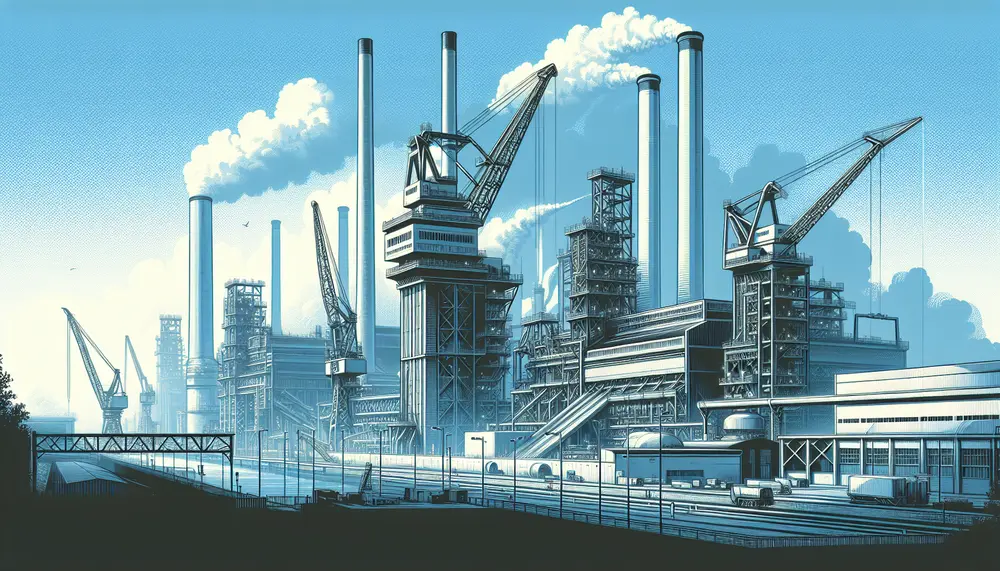

The global steel industry functions as the backbone of modern infrastructure. Spanning countless applications, from construction to transportation, it stands...

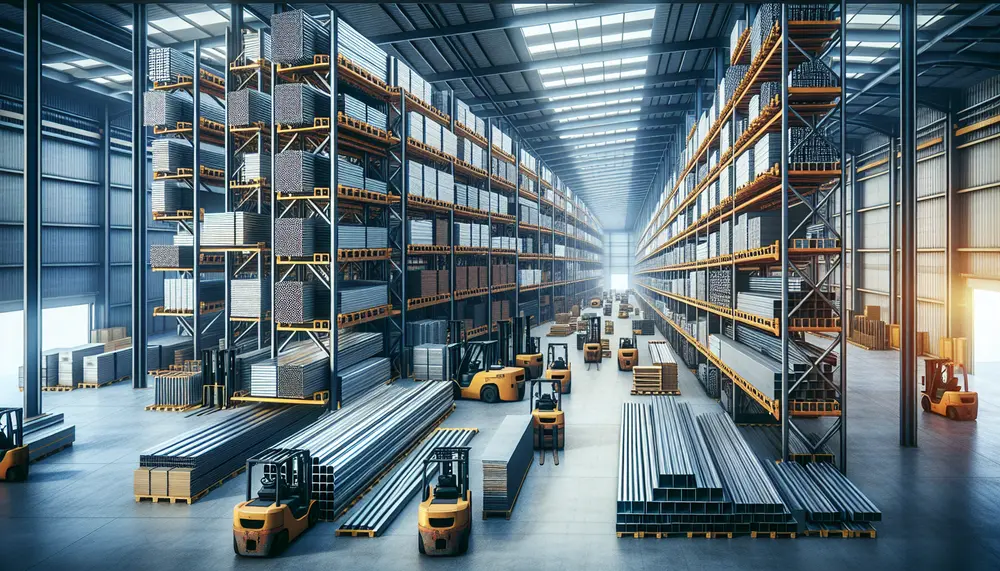

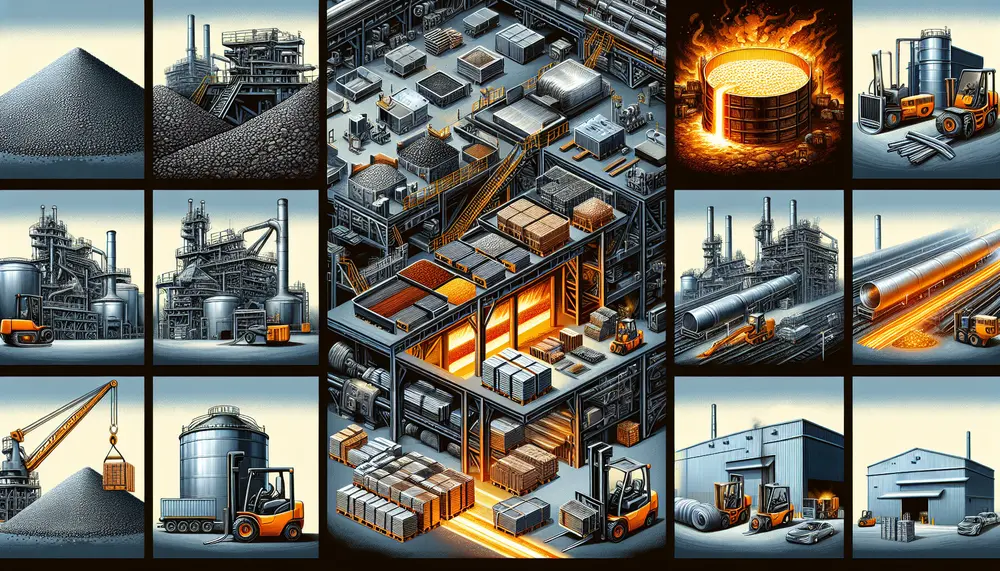

Grasping the concept of steel production by company is fundamental for anyone interested in the steel industry. Each steel production...

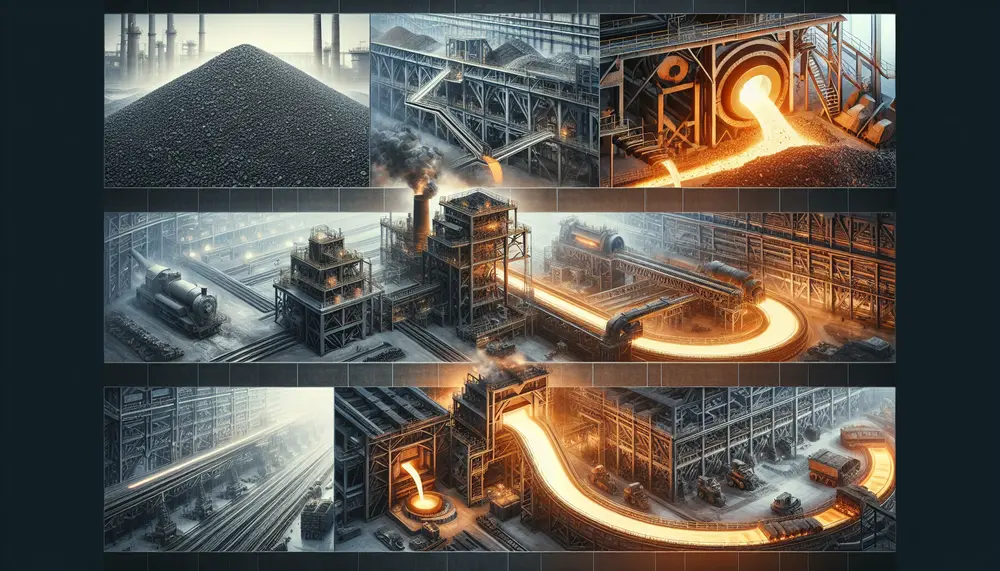

The steel making process is a fascinating journey that transforms raw materials into the world's most versatile building material. Steel...

The steel industry serves as a backbone to global development, providing a critical foundation for various sectors, from construction to...

The steel manufacturing process is a cornerstone of industrial development, shaping the skeleton of our modern infrastructure. It is a...

Steel production, a critical sector of the global economy, is not purely a matter of industrial processes and economic gain....

Steel production is a vital industry that lies at the heart of modern civilization. Europe, in particular, has a rich...

Steel making is a complex yet fascinating process that transforms raw materials into the strong and versatile metal we see...

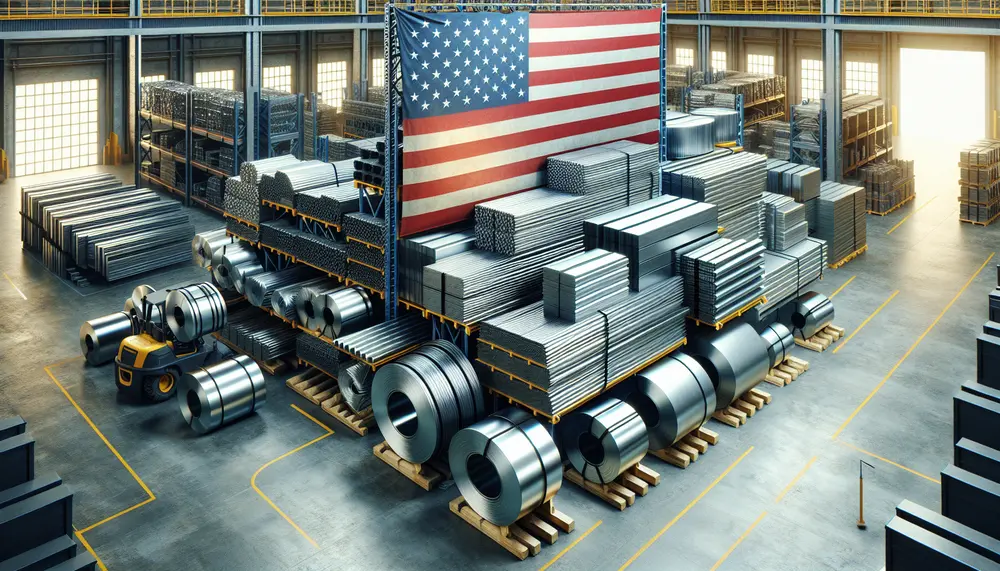

When we delve into steel production by state, we embark on a journey to uncover the intricate tapestry of an...

When we talk about green steel, we are referring to steel produced using methods that significantly lower or even completely...

At the core of steel production lies a highly energy-intensive process that consumes significant amounts of resources to transform raw...

At its core, quenching is a critical process in steel production that involves the rapid cooling of a metal to...

The landscape of steel production in Africa is as diverse as its geography. The continent's industry is steadily growing, although...

At the heart of modern infrastructure and construction is steel, a critical material that shapes the skeleton of our urban...

The outbreak of World War II signified a period of intense conflict that spanned the globe, but it was also...

When we talk about steel production on a state-wise level, we're delving into the intriguing geographical distribution of an industry...

Steel production statistics are a crucial barometer for gauging the health of both the global economy and the steel industry....

Steel production, a vital industry in New Zealand, has been instrumental in shaping the nation's infrastructure and economy. While it...

When it comes to choosing roofing materials, durability is a top concern for homeowners and builders alike. Steel roofing products...

When it comes to steel products, the quality of the material is paramount for ensuring durability, performance, and safety in...

The roots of steel production in Wales can be traced back to a time where the rich natural resources of...

The realm of steel production in Thailand is marked by a robust and dynamic landscape, underpinned by the country's strategic...

Unlocking the potential of any industry begins with understanding its current state and future opportunities. Steel production in Oman is...

Norway's steel production landscape stands as a testament to innovation and sustainability. The industry is characterized by a robust infrastructure...

When we talk about steel production in Mexico, we're delving into a sector that has become a cornerstone of the...

Steel production has long been the cornerstone of Luxembourg's economic landscape, forging a path for growth and stability in this...

Steel production in Kuwait has been steadily ascending, reflecting the nation's commitment to diversifying its economic sectors beyond the traditional...

Japan's journey to becoming a global powerhouse in steel production is a remarkable tale of resilience and innovation. From the...

The steel industry forms the backbone of industrialization and is a barometer of economic strength. Steel production on a global...

As we delve into the steel production landscape in Zambia, it is essential to grasp the country's unique position in...

At the heart of every soaring skyscraper, bridge, and automobile lies the strength of steel. The journey from raw material...

Steel production is a dynamic industry, integral to global economic development. Comprehending trends in steel production volume is essential for...

At the heart of the modern industrial landscape, steel production machinery is a critical component that shapes the efficiency and...

When we discuss steel production in Germany, we're delving into the heart of a nation renowned for its engineering prowess...

The traditional method of steel production has long been rooted in processes that consume significant amounts of coal, primarily in...

The United Arab Emirates has been witnessing an unprecedented surge in steel production, which marks a significant shift in the...

The story of steel production is a tale of human ingenuity and relentless progress. At the dawn of the 20th...

The landscape of steel production in Nigeria is a complex and multifaceted industry, integral to the country's industrial development. As...

When delving into the complex world of steel production, one of the most effective tools at our disposal is the...

The steel industry is a pivotal part of the Dutch economy, intricately woven into its industrial fabric. Recognized for its...

Steel plays a critical role in the growth and development of modern economies, and Malaysia is no exception. To comprehend...

Turkey's steel industry has long stood as a cornerstone of the country's economy, contributing significantly to its financial stability and...

Steel production is a cornerstone of modern industry, and it has come a long way from its early days. From...

The steel production outlook for 2023 and the years to follow is molding the very foundation of the steel industry,...

In the wake of dynamic economic transformation, Vietnam's steel production industry is flourishing, marking an impressive comeback after facing numerous...

Forecasting steel production involves predicting the future output of steel, a critical material for countless industries worldwide. This process requires...

Steel is the backbone of modern industry, a critical element in construction, automotive, and numerous other sectors. When we talk...

India stands as a key player in the global steel industry, with its unique position shaping the dynamics of both...

China's steel industry stands as a cornerstone of its burgeoning economy, with the country firmly established as the world's largest...

The world of steel production is a vast and complex network that extends across the entire globe. It's a sector...

At the core of steel production lies an intricate balance of raw materials, each playing a vital role in the...

Die Herstellung von Stahl gehört zu den grundlegenden Industrieprozessen, die unsere moderne Welt prägen. Doch was genau ist Stahl und...

If we were to look at a map of global steel production, we'd find a widespread practice spanning across continents....

Welcome to the fascinating world of modern steel production techniques. Steel, a critical part of our daily lives, is produced...

Welcome to the fascinating world of steel production. Steel, an alloy mainly composed of iron and a small amount of...

The steel industry stands as a significant player in the global economy, responsible for an entire chain of value and...

Steel production is a complex process that begins with the mining of iron ore and other raw materials. In the...

Steel production data refers to the collection of concrete measurements that provide crucial insights into the function and operation of...

In order to fully grasp the concept of steel production, it's crucial to understand what steel actually is. In essence,...

Efficiency is a crucial factor in the highly competitive steel industry. As companies strive to meet the increasing demand for...

When it comes to construction, manufacturing, and various other industries, steel plays a pivotal role due to its exceptional properties...

Steel, an alloy of iron and carbon, is an essential material that has shaped our modern world. From towering skyscrapers...

Welcome to our comprehensive overview of the steel making process. With its roots tracing back to ancient times, steel production...

Welcome to our discussion about the steel making process and why it's so important. Steel, a versatile and durable material,...