Posts on the Topic Carbon

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

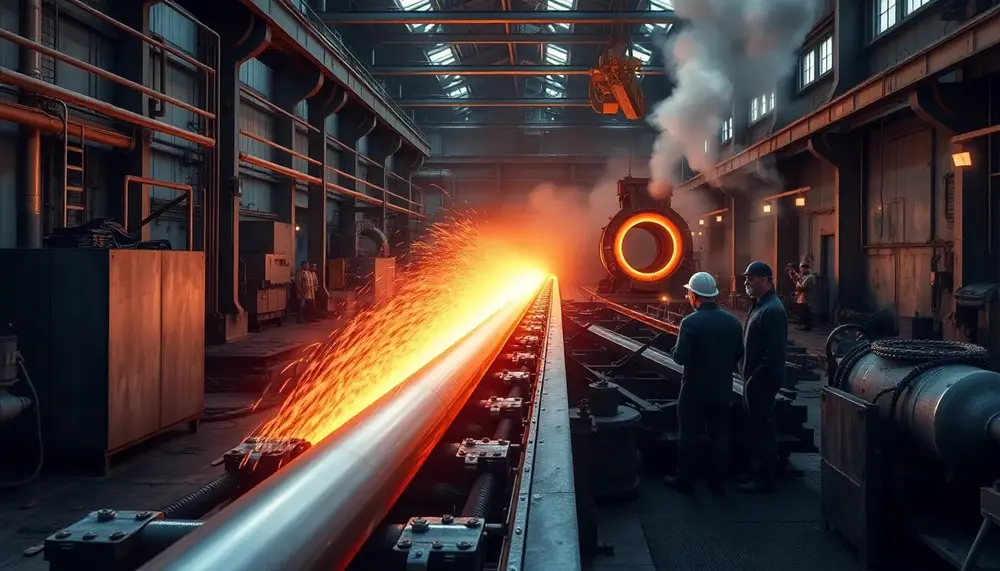

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

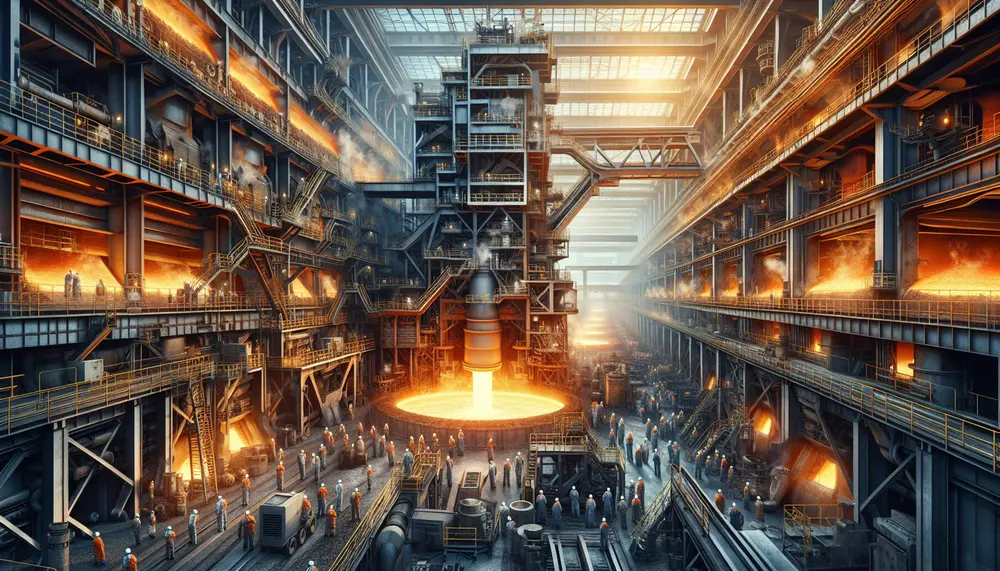

Steelmaking, particularly through traditional blast furnace methods, significantly contributes to environmental degradation by emitting greenhouse gases like CO2 and other pollutants. Transitioning to greener technologies such as Electric Arc Furnaces (EAF) could reduce these emissions but requires substantial investment and...

The article discusses the steel industry's transition from coal-based production to more sustainable methods due to climate change concerns, highlighting innovations like hydrogen use and renewable energy integration. It outlines both environmental impacts of traditional methods and pros and cons...

Steel production is essential to modern industry but generates significant emissions, with the traditional Blast Furnace-Basic Oxygen Furnace (BF-BOF) method being particularly carbon-intensive. Innovative strategies like smart manufacturing and alternative energy sources are being adopted to reduce these environmental impacts,...