Posts on the Topic Efficiency

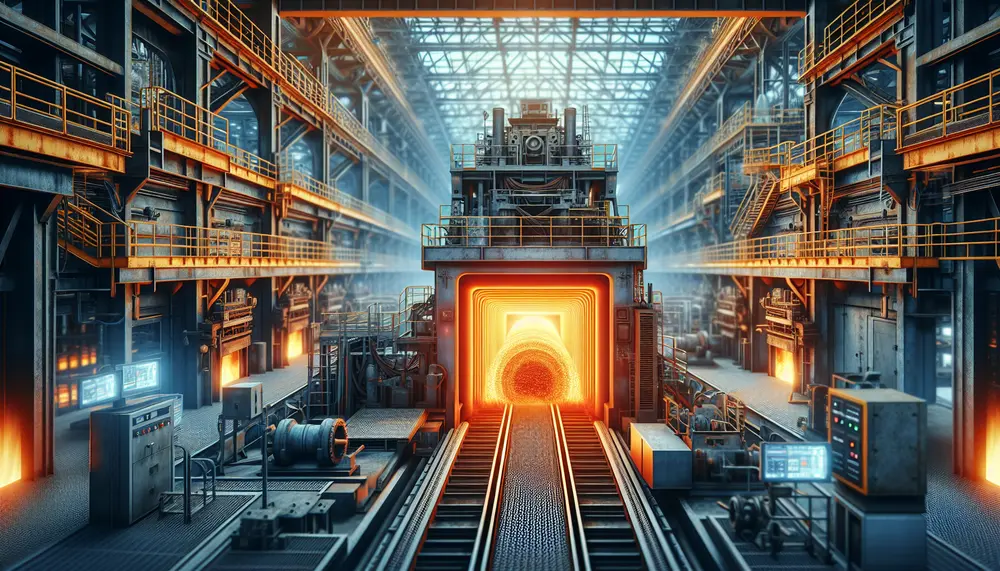

The transformation of steel production, marked by innovations like the Bessemer Process and later advancements, revolutionized industries by enabling faster, cheaper, and higher-quality steel manufacturing. These breakthroughs fueled industrial growth, urbanization, modern infrastructure development, and laid the foundation for a...

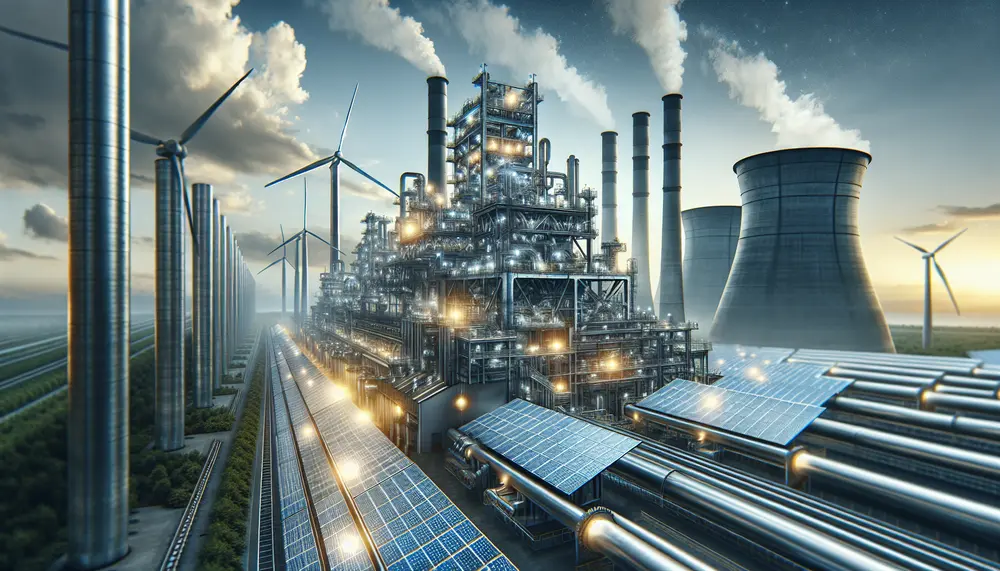

Danieli is revolutionizing steel production by integrating advanced, sustainable technologies like the Steel Plant Model and green solutions to enhance efficiency and reduce environmental impact. Their innovative approach combines adaptability, energy optimization, and emission reduction while setting new industry benchmarks...

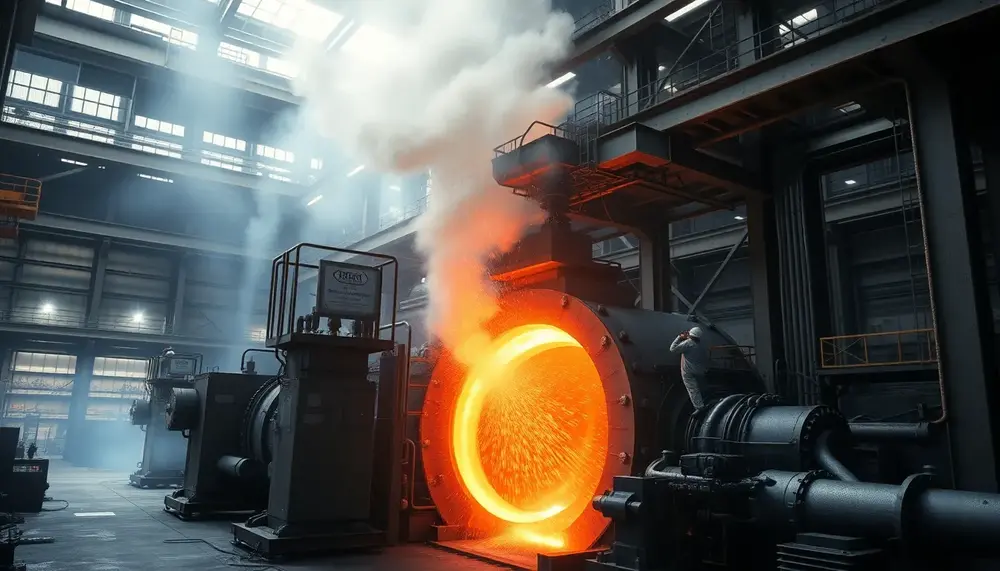

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

CFD steelmaking jobs are on the rise, offering a blend of technology and metallurgy to optimize processes in the steel industry through simulations that enhance efficiency and sustainability. Professionals in this field require technical proficiency, software expertise, analytical skills, problem-solving...

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

Steelmaking universities offer a blend of theoretical and practical education in metallurgical engineering, focusing on the science behind metal properties and production processes. Students learn through courses ranging from thermodynamics to advanced materials engineering, with hands-on experience in modern labs...

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...