Posts on the Topic Steel-production

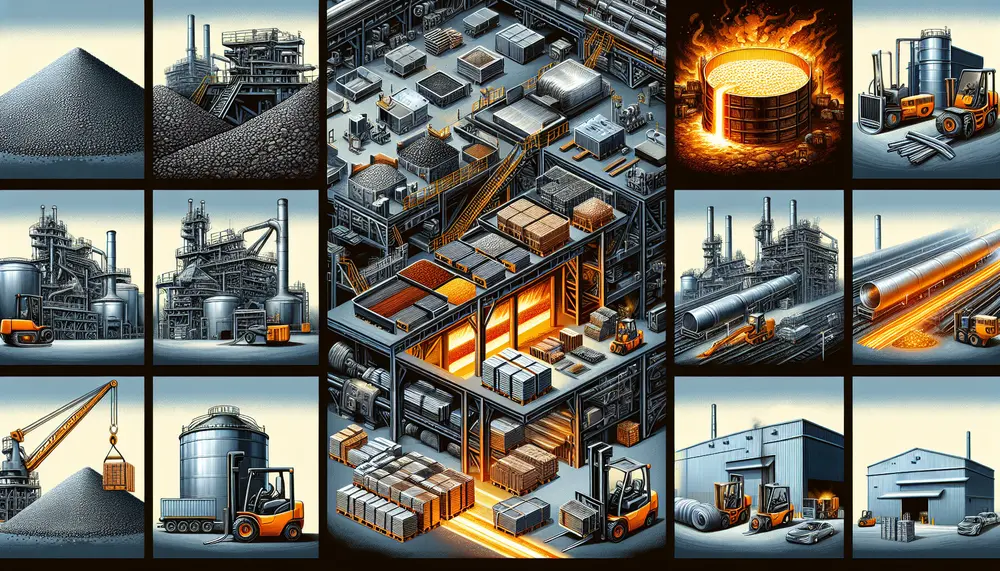

Secondary steelmaking refines and customizes steel after primary production, enabling precise control over composition and purity to meet modern industry demands. Key stages include deslagging, alloy addition, temperature adjustment, degassing, inclusion modification, and homogenization using advanced technologies like ladle furnaces...

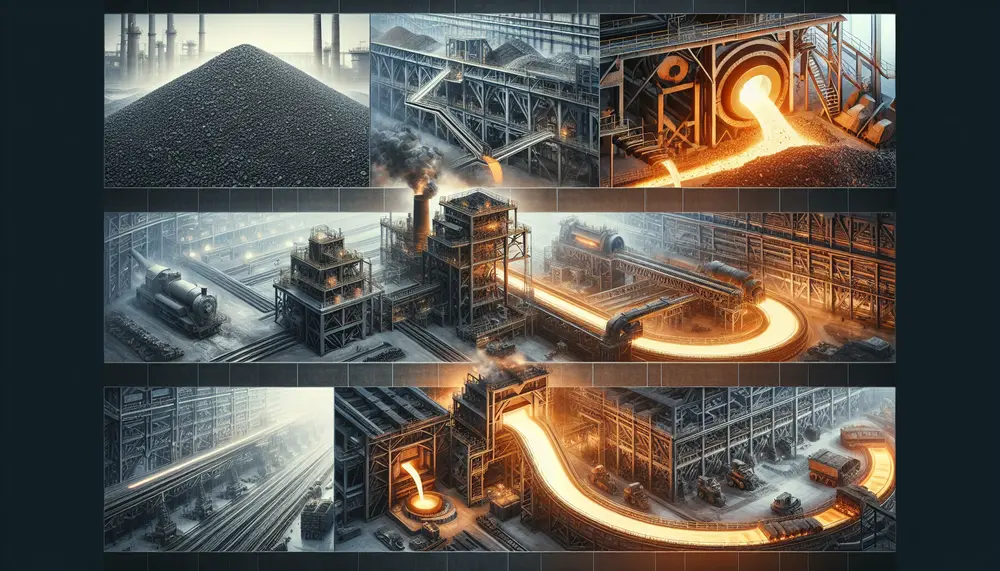

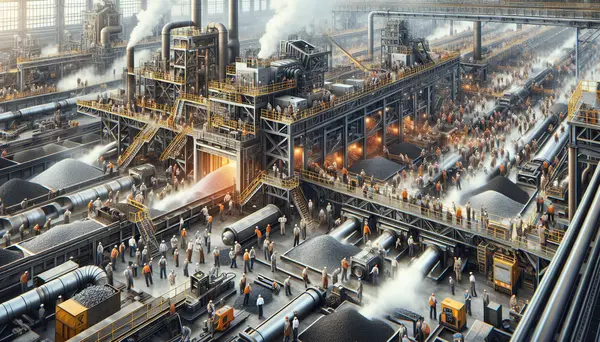

Steelmaking is vital to modern civilization, driving economies, infrastructure development, and sustainability efforts. The industry relies on two main methods—Blast Furnace (BF) for large-scale production with higher emissions and Electric Arc Furnace (EAF) for flexibility and lower environmental impact—shaping a...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

Steel production is intertwined with human rights, necessitating ethical responsibility to protect workers and communities throughout the supply chain. The industry faces challenges such as unsafe working conditions and environmental impacts but is moving towards addressing these through adherence to...

Steel production data, encompassing crude steel amounts produced by countries, trade flows and market prices, provides crucial insights into the global steel industry's operations. This information is essential for understanding supply-demand dynamics in the market and guiding business strategies or...

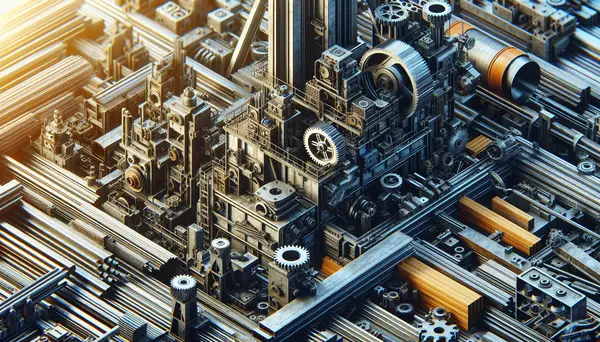

Steel innovation, the development and implementation of new technologies in steel production, plays a crucial role in industrial progress by improving efficiency, quality and sustainability. Recent advancements include more efficient resource use and waste reduction, recycling processes for high-quality steel...

New steel making technologies are emerging to increase productivity, quality and reduce environmental damage. These include the Organic Rankine Cycle (ORC) Technology that generates electricity from waste heat, the Hydrogen Breakthrough Ironmaking Technology (HYBRIT Process) for carbon-free production, Jet Process...

The steel industry, responsible for about 8% of global CO2 emissions, is under increasing pressure to reduce its environmental impact. Companies are exploring strategies such as improving efficiency in conventional processes, using alternative technologies like biomass and carbon capture, complying...