Table of Contents:

Understanding Steelmaking Refractories and Their Importance

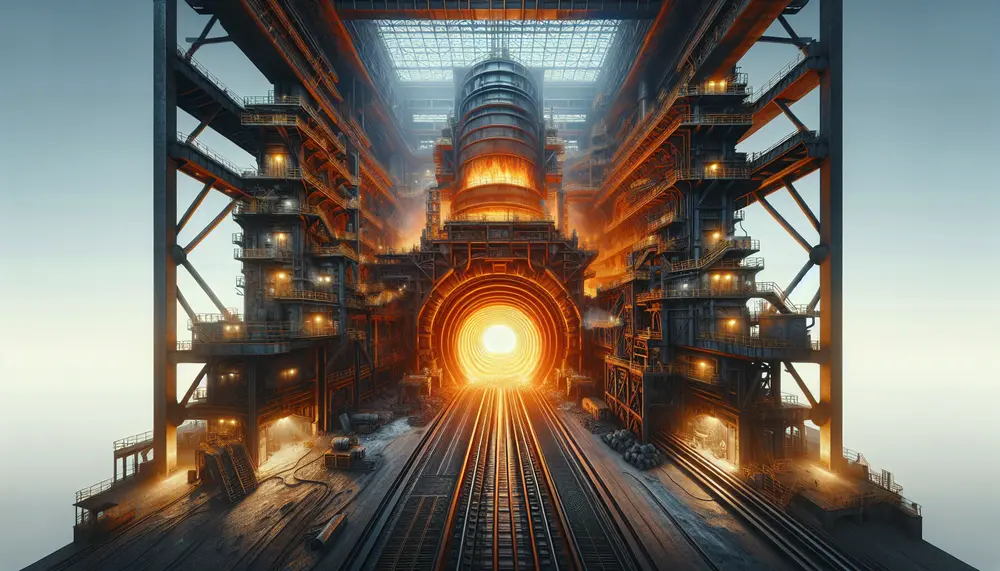

Steelmaking refractories, often overlooked but vital components, serve as the backbone of the steel industry. Refractories are specialized materials made to withstand extreme temperatures and corrosive environments, thus facilitating the high-temperature processes necessary for steel production. These materials line the interiors of furnaces, ladles, and other containers used in steelmaking, protecting the structural integrity of these vessels and ensuring the quality and purity of the steel produced.

The importance of refractories extends beyond mere functionality. They significantly impact the efficiency, safety, and cost-effectiveness of steel production processes. By enabling higher temperatures and providing robust resistance against heat, thermal shock, and chemical wear, refractories allow for improved metallurgical control and efficiency in steel production. This not only enhances the product quality but also reduces downtime caused by equipment maintenance or failures, thereby optimizing production cycles and reducing operational costs.

Furthermore, the choice of refractory material can influence the environmental impact of steel production. Advanced refractory materials can help in minimizing energy consumption and reducing emissions by enhancing heat retention within furnaces and reducing the frequency of replacements due to wear and tear.

Types of Refractories Used in Steel Production

Different types of refractories are utilized in steel production, each chosen based on their properties and the specific requirements of the steelmaking process. These varying types are crucial for different stages of steel production, from melting to final output handling.

| Type | Composition | Common Usage |

|---|---|---|

| Magnesia-Carbon (MgO-C) | Magnesia with 70-75% MgO and 16-20% graphite | Used primarily in converters and electric arc furnaces; known for its excellent thermal shock resistance and refractoriness under load. |

| Alumina-Silicate | Consists of alumina (Al2O3) and silica (SiO2) | Ideal for areas with high thermal cycles, particularly in ladle covers and certain furnace zones. |

| High-Alumina | High content of alumina, often more than 45% | Used in areas demanding high wear resistance and good mechanical strength, like furnace hearths and floors. |

| Basic Bricks | Composed mostly of magnesia, dolomite, or chrome | Suitable for the lining of steelmaking furnaces due to their excellent alkaline resistance. |

Each type of refractory is chosen based on specific characteristics such as melting point, thermal stability, chemical inertness, and resistance to wear and thermal shock. These characteristics ensure the refractories meet the intense and varied demands of the steelmaking environment.

Key Functions of Refractories in Steelmaking

Refractories perform several pivotal functions in the steelmaking process, each contributing to the overall efficiency, safety, and quality of steel production. Understanding these functions helps in appreciating the critical role that refractories play in sustaining the steel industry.

- Containment of Molten Metal: Refractories provide a crucial barrier between molten metal and the structure of the steelmaking furnaces, preventing metal contamination and structural damage.

- Thermal Insulation: They help in maintaining the requisite high temperatures essential for melting and refining steel. This insulation capability minimizes heat loss, resulting in energy savings and consistent production temperatures.

- Chemical Resistance: Steelmaking involves complex chemical processes, including exposure to severe slags. Refractories are designed to resist these harsh chemical environments, thereby protecting the integrity of the furnace and maintaining the purity of the steel.

- Mechanical Strength: The physical strength of refractories ensures that they can withstand the considerable mechanical stress imposed by the weight of molten metal and the operational rigors of steel production.

- Control of Metal Purity: By providing a non-reactive barrier between the metal and external contaminants, refractories help in maintaining the chemical composition and purity of the steel being produced.

Each of these functions highlights the indispensable nature of refractories in steelmaking processes, showcasing their role not just as passive protective elements, but as active enhancers of production quality and efficiency.

Challenges Faced by Refractories During Steel Production

Despite their robust design and essential role, refractories face numerous challenges during the steelmaking process that can impact their performance and longevity. These challenges are a direct result of the extreme conditions under which refractories operate.

- High Temperature Fluctuations: Refractories are subjected to extreme temperatures that can exceed 1600°C (2912°F). Frequent temperature fluctuations cause thermal stress, leading to cracking and spalling.

- Corrosive Slag: The chemical interaction between refractories and the various components of slag can lead to degradation. Slag often contains harmful components like silica (SiO2), alumina (Al2O3), lime (CaO), and magnesia (MgO), which can erode refractory materials over time.

- Mechanical Wear and Tear: The abrasive nature of raw materials and the mechanical impact from charging and tapping processes contribute to wear and tear, gradually deteriorating the refractory's structure.

- Oxidation: In oxygen-rich environments, refractories, especially those containing carbon, are prone to oxidation. This oxidation can significantly weaken the refractory, reducing its lifespan and effectiveness.

- Thermal Shock: Rapid changes in temperature can cause thermal shock, leading to cracks and disintegration of the refractory material. This effect is particularly severe when cold raw materials are suddenly introduced into a hot furnace.

These challenges necessitate ongoing advancements in refractory technology and materials science to enhance the durability, efficiency, and overall performance of refractories in steel production environments.

Innovations and Advances in Refractory Technology

As the steelmaking industry evolves, so too does refractory technology. Recent innovations and advances are crucial in addressing the operational challenges refractories face, enhancing their durability, efficiency, and overall performance. These developments reflect a commitment to improving the sustainability and cost-effectiveness of steel production.

- Enhanced Material Compositions: New formulations of refractory materials include additives that improve properties such as thermal shock resistance and oxidation resistance. For example, the incorporation of nano-scale additives can significantly reinforce the microstructure of refractories.

- Non-carbon-based Refractories: Innovations have led to the development of non-carbon refractories for oxidizing environments, reducing issues related to the oxidation of traditional carbon-containing refractories.

- Improved Installation Techniques: Advances in the installation processes, such as better gunning and casting techniques, ensure more uniform and stable refractory linings, which enhance the lifespan and performance of these materials.

- Smart Refractories: Embedding sensors within refractory linings is a groundbreaking development. These sensors can monitor temperature, pressure, and chemical changes in real-time, providing invaluable data that can lead to predictive maintenance and operational optimization.

- Recycling and Reuse: Focus on sustainability has led to processes that allow for the recycling of used refractories, reducing waste and the demand for raw materials.

These technological advancements are not just enhancing the functionality and longevity of refractories but are also playing a crucial role in reducing the environmental footprint of the steelmaking industry.

The Economic Impact of Refractories on the Steel Industry

The economic impact of refractories on the steel industry is multifaceted, influencing operational costs, production efficiency, and overall profitability. Refractories are not merely an expense; they are an investment that can significantly affect the economic health of steelmaking operations.

- Enhancing Production Efficiency: High-quality refractories improve the efficiency of steel production by reducing heat loss and maintaining consistent temperature levels. This results in lower energy costs and faster production rates, contributing to higher throughput.

- Extending Furnace Lifespan: Durable refractories that can withstand harsh conditions and frequent temperature fluctuations reduce the need for frequent replacements. This prolongs the lifespan of furnaces and other steelmaking equipment, leading to cost savings on maintenance and downtime.

- Reduction in Material Consumption: Advanced refractories often have higher performance metrics, which means less raw material is consumed per batch of steel produced. This optimizes material usage, leading to direct cost savings.

- Minimizing Production Interruptions: The stability and reliability of refractories directly impact the continuity of production processes. High-performance refractories reduce the frequency and duration of unplanned outages, thereby mitigating the substantial financial risks associated with production interruptions.

- Compliance and Environmental Costs: With stricter environmental regulations, the use of eco-friendly refractories can help steel plants lower emissions and environmental impact, potentially reducing regulatory fines and contributing to a greener reputation.

The strategic choice and maintenance of refractories can, therefore, have a profound economic effect, optimizing operational costs and enhancing the competitive edge of steel producers.

Sustainability and Environmental Considerations in Refractory Design

In an era where sustainability is a critical global concern, the design and operation of refractories in steelmaking have also evolved to address environmental considerations. Advances in refractory technology not only improve performance and cost-efficiency but also significantly contribute to environmental protection.

- Reducing Energy Consumption: Modern refractories are designed to improve heat retention within furnaces, which minimizes energy usage and reduces carbon emissions. Energy-efficient refractories contribute directly to achieving sustainability goals in steel production.

- Lowering Emission Levels: Eco-friendly refractories are formulated to emit fewer pollutants during their lifespan. This is crucial for steel plants looking to comply with increasingly stringent environmental regulations aimed at reducing industrial emissions.

- Enhancement of Material Efficiency: Advanced refractories often have a longer lifecycle, reducing the frequency of replacement and the associated waste. Furthermore, the focus on recycling used refractory materials helps in minimizing the extraction of new raw materials, thereby reducing the environmental footprint.

- Development of Non-Hazardous Materials: Research and development efforts are increasingly focusing on eliminating hazardous substances from refractory materials. This shift not only helps in reducing the potential environmental harm but also protects worker health in steelmaking facilities.

- Innovations in Waste Management: The refractory industry is adopting practices such as the reuse and recycling of spent refractories. This approach diverts significant quantities of waste from landfills and repurposes it in useful applications, contributing to a circular economy.

These advancements reflect a broader shift towards more sustainable and environmentally friendly practices in the steel industry, underlining the role of refractories not just as functional components of steel production but as critical elements in the sustainability dialogue.

Future Trends in Refractory Technology and Steelmaking Practices

The future of refractory technology and steelmaking practices is poised to be shaped by several emerging trends that aim to enhance performance, sustainability, and cost-efficiency. These trends highlight the ongoing innovation within the sector and the industry's adaptation to new global standards and expectations.

- Integration of Advanced Technologies: The refractory industry is exploring the use of artificial intelligence and machine learning to optimize the performance of refractories. Predictive maintenance models can forecast when refractories need to be replaced or maintained, thus minimizing downtime and enhancing operational efficiency.

- Greater Emphasis on Sustainability: Future refractory solutions will likely focus more intensely on environmental impact. This includes developing materials that are fully recyclable and those that offer improved performance to further reduce greenhouse gas emissions from steel plants.

- Customization of Refractory Compositions: Advances in material science will enable more tailored refractory solutions that are specific to the operational demands of different steel mills. This customization will optimize both performance and the lifespan of refractories.

- Increased Use of Renewable Energy Sources: As steel mills seek to decrease their carbon footprint, the incorporation of renewable energy sources within refractory manufacturing processes is forecasted to increase. This shift will aid in reducing the overall environmental impact of both the refractory and steelmaking industries.

- Development of Smart Refractories: The concept of smart refractories, equipped with sensors for real-time monitoring and data analysis, will progress. These technologies will provide critical insights into the conditions within high-temperature environments, allowing for precise adjustments and improvements in steel production practices.

Embracing these future trends will be crucial for steelmakers and refractory manufacturers as they adapt to the evolving landscape of global manufacturing, with an increasing focus on efficient, sustainable, and high-performance solutions.

Conclusion: The Critical Role of Refractories in Modern Steelmaking

The role of refractories in modern steelmaking extends far beyond their basic functionality as heat-resistant materials. As we have explored, these components are pivotal in enhancing the efficiency, safety, and sustainability of steel production processes. The evolution of refractory technology continues to align with the dynamic demands of the steel industry, addressing both operational challenges and environmental concerns.

Refractories are at the heart of steel production, safeguarding the equipment and ensuring the quality of steel. Their ability to withstand extreme conditions while maintaining performance is crucial to preventing downtime and optimizing production output. The strategic importance of refractories is underscored by their impact on the economic aspects of steelmaking, influencing everything from cost reduction to environmental compliance.

In conclusion, as the steel industry moves towards more sustainable and technologically advanced practices, the development of refractories will continue to be a key area of focus. Future innovations in refractory materials and technologies are expected to further revolutionize this sector, enhancing the global steel production landscape. These advancements promise not only to improve the efficiency and sustainability of steelmaking but also to propel the industry towards a greener, more cost-effective future.

FAQ on the Essential Role of Refractories in Steelmaking

What are refractories and why are they important in steelmaking?

Refractories are heat-resistant materials that line high-temperature furnaces and other processing units in the steel industry. They are crucial because they protect the structural integrity of steelmaking furnaces and aid in maintaining the necessary high temperatures for metal processing.

What types of refractories are used in steel production?

There are several types of refractories including magnesia-carbon (MgO-C), alumina-silicate, high-alumina, and basic bricks. Each type is chosen based on its resistance to heat, thermal shock, and chemical corrosion, which are necessary for different stages of steel production.

What challenges do refractories face during steel production?

Refractories are exposed to harsh conditions including extreme temperatures, mechanical wear and tear, aggressive slag, and thermal shock. These conditions can lead to degradation, necessitating frequent maintenance and replacement.

How have refractory technologies evolved to improve steel production?

Refractory technology has advanced with the development of non-carbon-based refractories and smart refractories, which include sensors for real-time monitoring and management. These advancements enhance durability, performance, and environmental compliance in steel production.

How do refractories contribute to sustainability in steelmaking?

Advances in refractory materials and designs focus on enhancing energy efficiency and reducing waste. They help in retaining more heat within furnaces and extend the life cycle of refractory materials, which contributes to lower energy consumption and reduced environmental impact.