Table of Contents:

Introduction to Iron and Steel Technology

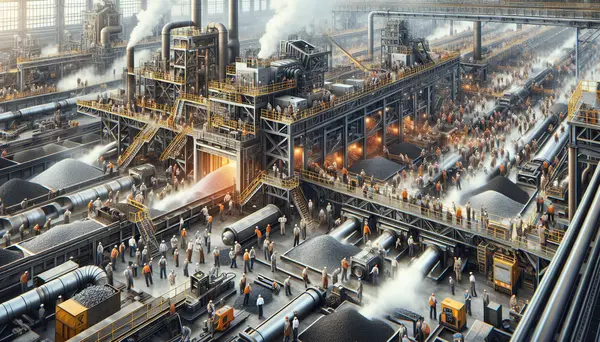

Welcome to our exploration of the latest innovations in iron and steel technology. For centuries, the evolution of iron and steel production has played a pivotal role in the advancement of society, underpinning everything from housing and transportation, to energy and digital technology. Today, the iron and steel industry is embarking on a new era of innovation, fueled by breakthroughs in automation, energy efficiency, and carbon reduction. Let's dive in and discover the fascinating world of iron and steel technology.

The Evolution of Iron and Steel Production

From the discovery of iron smelting around 1200 BC to the rise of modern steelmaking in the 19th century, the production of iron and steel has continually evolved in parallel with societal development. In the past, considerable manual labour and intense heat were needed to transform iron ore into a usable product. Fast forward to today, and you see an industry transformed by technology.

The modern steelmaking process started with Henry Bessemer's invention of the Bessemer converter in the mid-1800s, which ushered in a new era of mass steel production. This was followed by the introduction of the basic oxygen furnace in the mid-20th century, which further increased the efficiency and scale of steel production.

In recent decades, the key trend has been towards increasing precision and efficiency in the production process. This is driven by advances in computational power and automation technology, as well as a wider shift towards more sustainable and environmentally-friendly manufacturing practices.

Pros and Cons of Latest Innovations in Iron and Steel Technology

| Pros | Cons | |

|---|---|---|

| Austempering Process | Creates a more structurally sound end product, reducing the risk of defects and increasing durability. | Takes longer and requires more energy, leading to higher production costs. |

| Direct Reduced Iron | Uses natural gas instead of coke, reducing CO2 emissions and energy usage. | Higher operating costs and less flexible in the materials it can process compared to traditional methods. |

| Nano Steel | Utilizes nano technology to create steel with high strength and ductility. | Still in the research and development stage. High production cost. |

The Role of Automation in Steel Manufacturing

In the journey towards the future of iron and steel technology, one breakthrough stands tall: Automation. From the use of robotics in handling raw materials to the employment of machine learning algorithms in predicting steel quality, automation has become a critical factor in modern steel manufacturing.

Automation aids in improving the productivity of steel plants by reducing potential errors and increasing the precision of the process. With advancements in technologies such as Artificial Intelligence (AI) and Internet of Things (IoT), we are now seeing fully automated plants where machines control the entire production process.

This not only boosts efficiency but also enhances safety by reducing human involvement in potentially hazardous processes. The integration of advanced software with manufacturing processes is a prominent example of how technology can streamline operations, maximize output, and reduce costs in the steel industry.

Energy Efficiency in Iron and Steel Technology

Another key focus in the evolution of iron and steel technology is energy efficiency. Historically, the production of steel has been an energy-intensive process, making it a significant contributor to global greenhouse gas emissions. However, the industry has made considerable strides in recent decades to reduce its energy consumption and limit its environmental impact.

One of the ways this is being achieved is through the use of advanced production technologies that require less energy. For instance, electric arc furnaces (EAFs), which use electricity to melt scrap steel, are now more prevalent due to their lower energy requirements compared to traditional blast furnaces.

Moreover, steel manufacturers are employing innovative processes that capture and reuse waste heat and gases produced during manufacturing. Examples of these include coke dry quenching, which recovers and reuses the heat produced during coke making, and top gas recovery turbines, which capture and utilize the pressure from excess blast furnace gas.

Such advances have resulted in significant gains in energy efficiency. According to the World Steel Association, energy intensity per tonne of crude steel has decreased by over 60% in the past 50 years.

Reducing CO2 Emissions in Steel Production

Reducing carbon emissions is a global priority, and the steel industry has made it a key part of its mission. Steel manufacturing is historically one of the largest industrial sources of CO2 emissions. Fortunately, advancements in iron and steel technology have allowed the industry to make substantial progress in this area.

New technologies such as carbon capture and storage (CCS) and carbon capture and use (CCU) are playing a significant role in reducing emissions. These technologies involve capturing CO2 emissions produced during the steelmaking process and either storing them underground (CCS) or using them as raw materials in other industries (CCU).

A notable innovation is the emerging usage of hydrogen in steelmaking. Hydrogen can replace coal in the direct reduction of iron ore, a process that produces steel with virtually no carbon emissions. Companies like Sweden's SSAB and Germany's Thyssenkrupp are pioneering this 'green steel' technology, ushering in a whole new era for the industry.

Furthermore, thanks to such initiatives, the iron and steel industry has seen a 37% reduction in CO2 emissions per tonne of steel since 1990, according to the World Steel Association.

Investments in Research and Development for Steel Production

Keeping up with the ever-evolving demands for stronger, lighter, and more sustainable steel requires substantial input from research and development (R&D) initiatives. Investment in R&D is fundamental to ensuring the continued growth and innovation within the iron and steel industry.

Emerging trends in R&D focus on enhancing production efficiency, optimizing the use of raw materials, reducing environmental impact, and creating high-performance steel for advanced applications. This is not just under the purview of private companies, but also involves collaborative efforts between academia, government bodies, and industry associations.

Exciting breakthroughs include optimizing the chemical composition of steel to achieve desired mechanical properties, using nanotechnology to enhance the properties of steel, and advancing the use of 3D printing in the production of steel parts.

Investments in R&D are crucial in sustaining the steel industry's drive for innovation and maintaining its pivotal role in the global economy.

The Impact of the Clean Energy Manufacturing Institute on Steel Technology

The Clean Energy Manufacturing Institute (CEMI), supported by the U.S. Department of Energy, is one of the global initiatives striving to provide renewable and energy-efficient solutions across various manufacturing industries, including the iron and steel sector.

CEMI has been instrumental in spurring innovative, clean technologies to significantly reduce carbon emissions and improve energy efficiency in steel production. Its role involves conducting research, developing new technologies, and promoting partnerships among government, industry, and academia.

One notable accomplishment of CEMI and its partners is the optimization of the steel reheating process, which led to a significant reduction in energy usage and emissions without compromising steel product quality. It also helped develop advanced, highly recyclable steels for the automotive industry, contributing to lighter, more fuel-efficient vehicles.

Through the work of organizations such as CEMI, the path to sustainable steel manufacturing becomes clearer, proving that an industrial revolution based on clean energy is not just possible, but well underway.

The Future of Iron and Steel Technology

As we gaze into the future of iron and steel technology, one thing is clear - it will continue to be shaped by advancements in automation, sustainability, and efficiency.

Increasing use of AI and robotics for automating a broader range of tasks will play a central role in boosting efficiency and productivity. Furthermore, innovations in energy-saving processes and recyclable steel products will drive environmental sustainability.

The role of 'green steel,' made using renewable energy or hydrogen instead of coal, will also be crucial in the industry's efforts to minimize its carbon footprint. The development and commercialization of green steel production could herald a new age of carbon-neutral steelmaking.

Emerging trends such as 3D printing of steel parts and the development of next-generation, high-performance steel grades for advanced applications in industries like aerospace and automotive, will continue to push the boundaries of innovation in steel technology.

The future of iron and steel technology promises to be as exciting and impactful as its storied past. With ongoing breakthroughs and the constant quest for improvement, the industry is well-poised to continue leading the way in technological innovation and sustainability.

FAQ on Innovations in Iron and Steel Technology

What role does precision play in steel production?

Precision plays a critical role in the steel production, ensuring a high standard of quality and performance across diverse applications ranging from construction to car manufacturing.

How do advanced technologies and automation influence the steel industry?

Automation and advanced technologies streamline the steel production process, reduce manual labor, increase safety, and boost the efficiency and accuracy of production. This significantly contributes to the high-tech nature of the contemporary steel industry.

What has been achieved in terms of energy efficiency and CO2 emission reduction in the steel industry?

The steel industry has made significant advancements in energy efficiency, reducing CO2 emissions by 37% since 1990. These innovations also help conserve resources and mitigate the industry's environmental impact.

How does the steel industry invest in research and development?

Investments in research and development focus on optimizing production processes, creating new steel grades, and discovering more sustainable processes. Innovation plays a critical role in the evolving steel industry.

What is the Clean Energy Manufacturing Institute?

The Clean Energy Manufacturing Institute is an initiative supported by the American Iron and Steel Institute (AISI). Its aim is to develop and implement cleaner and more efficient steel manufacturing technologies to further minimize environmental impacts.