Table of Contents:

Understanding Steel Rollformed Products

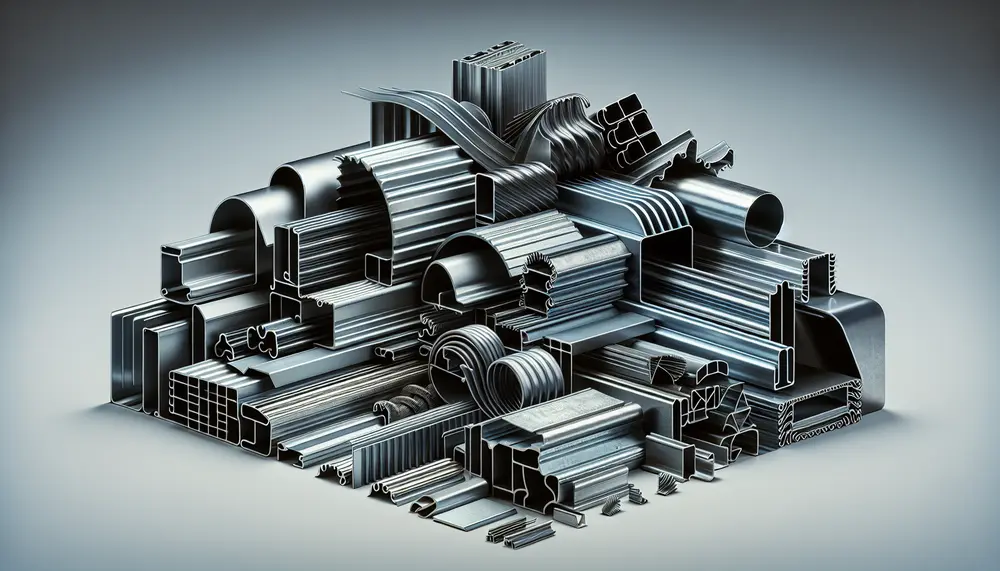

Steel rollformed products are at the core of modern construction and manufacturing, playing a crucial role across diverse sectors. These components are crafted through a precise process known as roll forming, where long strips of metal are continuously bent into desired shapes by passing them through sets of rolls. Each roll in the sequence makes a small part of the bend, until the final shape is achieved. This method allows for the creation of uniform, high-quality parts that can be produced in large quantities efficiently.

The inherent strength and adaptability of steel make it an ideal material for roll forming. Steel rollformed products come in various forms, including panels, sections, and trims for buildings, as well as more complex shapes for automotive parts or machinery. These products offer designers and engineers a high degree of versatility, thanks to steel's ability to be shaped into almost any form while maintaining its durability and structural integrity.

Another key aspect of steel rollformed products is their compatibility with advanced manufacturing processes. Enhanced by computer-controlled systems, modern rollforming machines can execute intricate designs and maintain tight tolerances, ensuring that each product meets specific requirements. This high precision is vital in applications where safety or design precision is paramount.

In summary, steel rollformed products are integral to industrial and commercial projects due to their versatility, precision, and strength. As we delve deeper into the world of steel rollforming, it becomes clear that the potential applications of these products are vast and indispensable in today's fast-paced construction and manufacturing landscapes.

The Rollforming Process Explained

The rollforming process is a highly efficient method for shaping metal sheets into custom profiles. It begins with flat steel coils, which are fed into a rollforming machine. Inside the machine, a series of paired rollers, each set configured for a specific bend, progressively shapes the metal. As the steel moves through these rollers, it transforms from its flat state into a longitudinal product with a consistent cross-sectional profile.

One of the stand-out features of this process is its continuous operation. Unlike other forming methods that may require stopping and starting, rollforming moves the steel through the rollers in a seamless flow. This non-stop motion contributes to the efficiency and speed of production, making rollforming excellent for creating long runs of consistent, high-quality parts.

The final product emerges from the end of the rollforming line cut to the desired length and ready for immediate use or further processing. Rollformed products can also include holes, notches, and other features integrated into the design, which are punched into the steel as part of the rollforming operation.

This manufacturing method offers several benefits over alternative processes. Rollforming provides high production rates, minimal material waste, and the ability to produce complex cross-sections that might not be feasible with other metal forming techniques. Through innovation and modernization, such as implementing CNC technology for greater precision and control, rollforming continues to be a leading solution for the mass production of steel products.

Comparing Advantages and Drawbacks of Steel Rollformed Products

| Pros | Cons |

|---|---|

| High strength-to-weight ratio | Initial setup cost can be high |

| Durable and long-lasting | Less flexibility with design changes once setup |

| Can be produced with tight tolerances | May require specialized equipment |

| Efficient for mass production | Skilled labor needed for operation and maintenance |

| Easily customized with a variety of finishes | Material limitations - not all metals are suitable for rollforming |

| Eco-friendly with possibilities for recycling | Limited to linear and planar geometries |

| Consistent quality and dimensional accuracy | Potential for material wastage if not optimized |

Key Industries Benefiting from Steel Rollformed Products

Steel rollformed products serve as fundamental components across a multitude of industries, each leveraging the unique benefits of these versatile materials. The construction industry, for instance, relies heavily on steel rollformed products for structural components such as beams, frames, and roofing panels. Their uniformity and strength are imperative in ensuring the integrity and longevity of buildings and infrastructure.

The automotive sector benefits from the high strength-to-weight ratio of rollformed steel, utilizing it for parts ranging from chassis components to trim pieces. The precision of rollforming allows for intricate designs that conform to the aerodynamic and safety standards required in vehicle manufacturing.

Another industry that capitalizes on the attributes of steel rollformed products is the energy sector. Specifically, within the realm of renewable energy, rollformed steel is used in the construction of solar panel frames and supports, providing the necessary durability to withstand environmental stress while maximizing efficiency.

Moreover, the commercial shelving and storage systems industries are beneficiaries of rollformed steel's load-bearing capabilities. Here, it is employed to create racking, shelving units, and other storage solutions that require reliability under constant and heavy use.

Agriculture also makes use of rollformed products for machinery and equipment. Similarly, home appliance manufacturers incorporate them into the design of their products, where metal components must meet strict specifications for safety and functionality.

In essence, key industries from infrastructure to green energy embrace the use of steel rollformed products, recognizing their intrinsic qualities of resilience, adaptability, and precision that drive innovation and efficiency in their respective fields.

The Advantages of Steel Rollformed Products in Construction

Within the construction industry, steel rollformed products bring a set of distinct advantages that enhance the overall building process. Among these benefits is the consistency of each piece produced. Rollforming offers unparalleled uniformity, which is essential for the structural integrity of construction projects.

Another advantage is the speed of assembly that rollformed products allow. With components that are ready to install upon delivery, construction timelines can be significantly reduced. This efficiency decreases labor costs and enables faster project completion times, which can be a critical factor in the fast-paced construction market.

Furthermore, the customizability of rollformed products plays a pivotal role in construction. Designers and architects can specify dimensions and shapes tailored to their projects, ensuring that the components integrate seamlessly. Rollforming can accommodate a wide range of profiles, from simple angles and channels to complex geometries, without sacrificing structural performance.

Additionally, steel rollformed products provide a level of durability that stands up to the rigors of construction sites and the demands of long-term use. This material choice means that buildings will have a longer lifespan with less maintenance required over time, representing a sustainable investment.

Lastly, the environmental impact is mitigated as rollforming tends to generate less waste compared to traditional cutting and machining processes. Steel is also recyclable, which aligns with green building practices and helps reduce the carbon footprint of construction projects.

Overall, the advantages that steel rollformed products offer make them an indispensable solution in the construction sector, combining practical efficiency with robust performance and environmental consciousness.

Customization and Design Flexibility of Rollformed Steel

The capability to tailor steel to meet specific design requirements is one of the hallmarks of rollforming technology. This customization extends far beyond simple modifications, giving designers and engineers the flexibility to innovate and create complex custom profiles. The rollforming process enables intricate patterns and precise dimensions that can be consistently reproduced, ensuring that each product meets exact design specifications.

One area where design flexibility is particularly beneficial is in the creation of architectural features. Rollformed steel can be shaped into aesthetically pleasing details that also serve structural purposes. This dual function is essential in modern architecture, where form and function often need to coalesce seamlessly.

From functional components like framing systems and support channels to decorative trims and panels, rollformed steel can be adapted to a diverse array of applications. The process allows for the integration of additional features like embossed patterns or predetermined holes for fasteners, which can streamline the construction process further.

Moreover, rollforming supports the use of a variety of finishing options. Steel products can be coated, painted, or finished with different textures and colors, presenting even more opportunities for customization and creative expression in designs.

The combination of these factors results in a powerful tool for the design and production of buildings and products. Rollformed steel's customization and design flexibility enable endless possibilities, helping to bring even the most ambitious designs to life while maintaining high standards of quality and performance.

Material Choices in Steel Rollforming

Steel rollforming is a versatile process that accommodates a variety of material choices, each with distinct properties to suit different applications and requirements. The selection includes cold-rolled steel, hot-rolled steel, high-strength steel, and stainless steel, among others.

Cold-rolled steel is known for its fine surface finish and superior dimensional accuracy. It is often used for parts where a clean, precise appearance is needed, as well as applications requiring tighter tolerances.

In contrast, hot-rolled steel is prized for its robustness and structural integrity. Its production process involves rolling the steel at high temperatures, making it easier to work with. Hot-rolled steel is typically utilized where the finish is not a primary concern, such as in structural components.

High-strength steel offers enhanced durability without adding significant weight, making it ideal for automotive and aerospace industries where performance and efficiency are critical.

Stainless steel, with its corrosion resistance, is the preferred option for applications exposed to harsh environmental conditions or where sanitary specifications must be met, such as in medical or food-processing equipment.

Aside from these common types, manufacturers may also choose alloys with specific characteristics, such as improved formability or increased tensile strength, to fulfill the unique needs of their projects.

Understanding the properties of each type of steel is essential in the rollforming process, as it dictates not only the functionality and lifespan of the final product but also impacts manufacturability and cost-efficiency. Selecting the appropriate material is a critical step in ensuring the desired outcome for rollformed steel products.

Innovations in Steel Rollforming Technology

Innovations in steel rollforming technology continue to transform the industry, driving improvements in efficiency, precision, and product capabilities. Leading-edge advancements are helping manufacturers meet the ever-evolving demands of a competitive market.

Advancements in inline processing are crucial. Modern rollforming lines incorporate operations such as punching, welding, and cutting within the rollforming sequence, which boosts productivity by reducing the need for secondary operations.

The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) has significantly enhanced the precision of rollformed products. CAD/CAM systems enable manufacturers to create highly accurate and complex product designs that can then be directly translated into machine instructions. This digitization streamlines the production process and minimizes errors.

Additionally, the application of automated control systems allows for more consistent quality and better management of material flow. Automation ensures that the rollforming process can be finely tuned and adjusted in real-time, allowing for quick and efficient changeovers to different product profiles.

Another innovation affecting the rollforming industry is the development of flexible rollforming machines. These machines can handle a wider range of profile shapes and sizes without the need for extensive retooling, vastly reducing downtime for setup changes.

Lastly, sustainability efforts are influencing technological developments. Aspects such as energy-efficient motors and regenerative drive systems not only lower power consumption but also contribute to the broader goal of reducing environmental impact.

These technological innovations in steel rollforming not only optimize production but also open up new possibilities for creating products that were previously challenging to manufacture. These advancements are crucial for the industry's adaptation to a future where versatility and sustainability are paramount.

Sustainability and Steel Rollformed Products

The conversation around sustainability has become increasingly important in manufacturing, and steel rollforming is no exception. This process, by its nature, supports environmentally conscious manufacturing through various aspects that reduce the industry's ecological footprint.

One of the key facets of sustainability in steel rollforming is the high rate of material utilization. The process entails minimal waste production as excess can often be recycled, ensuring that material efficiency is maximized. Additionally, steel itself is a highly recyclable material. As a result, steel rollformed products contribute to a circular economy where materials can be reused and recycled, reducing the need for virgin resources and minimizing waste.

Enhancements in machine design also contribute to sustainability. The adoption of energy-efficient machinery helps to lower power consumption in manufacturing operations. Moreover, the rollforming process conserves energy by eliminating the need for heat-intensive practices, like those required in extrusion or forging.

The longevity of rollformed steel products is another factor bolstering sustainability. The durability inherent to steel diminishes the frequency of replacements and repairs, thereby reducing the materials and resources necessary over the lifetime of a project.

Furthermore, technological progress, such as improved predictive maintenance and smarter production planning, helps to avoid unnecessary downtime and waste, ensuring that resources are utilized judiciously.

Altogether, sustainability is a key consideration in the evolution of steel rollforming. Through its efficient material usage, recycling capabilities, energy-conscious production, and durability of the end products, steel rollforming aligns with practices that favor reduced environmental impact.

Choosing the Right Steel Rollformed Products Provider

Selecting the appropriate provider for steel rollformed products is crucial to ensure the success of any project. It requires careful consideration of several factors that impact the quality, reliability, and service you will receive.

Firstly, evaluate the experience and expertise of the provider. Providers with a long-standing presence in the industry often have a proven track record and in-depth knowledge of both the rollforming process and the applications of their products.

Quality certifications, such as ISO standards, are another essential consideration. These certifications indicate that the provider adheres to rigorous quality management and product standards, which can be critical for ensuring that the steel rollformed products meet your project's specifications.

Additionally, the supplier's capability to offer customization and flexible production runs is important. A provider that can adapt to your project's unique requirements, whether for small batches or specialized profiles, can be a valuable partner in achieving your design and production goals.

The provider's commitment to sustainability and environmental responsibility should also be assessed. As global focus shifts towards greener practices, working with a supplier that prioritizes eco-friendly processes can align with your company's values and objectives.

Lastly, consider the provider's customer service and support offerings. The ability to provide technical assistance, prompt communication, and reliable after-sales service can significantly enhance your experience and ensure smooth project execution.

Choosing the right steel rollformed products provider is a vital decision that influences the efficiency, outcome, and sustainability of a project, making it important to select a partner that aligns with your operational values and project needs.

Case Studies: Successful Applications of Steel Rollformed Products

Examining case studies provides valuable insights into the successful applications of steel rollformed products across various industries. These real-world examples showcase the effectiveness of rollforming in meeting diverse challenges and creating impactful solutions.

A notable case involves the use of rollformed steel in large-scale infrastructure projects. For instance, the construction of a major bridge utilized custom rollformed beams that provided the necessary strength and support while allowing for rapid assembly. This application highlighted rollforming's ability to contribute to structural integrity and project efficiency.

In the commercial sector, a retail chain implemented steel rollformed products for its shelving and storage systems. The rollformed components featured precise dimensions and a high load-bearing capacity, which optimized the store's layout and improved the overall shopping experience for customers.

The automotive industry frequently adopts rollformed steel for manufacturing various vehicle components. A particularly successful application was in the production of safety-critical elements, where the dimensional accuracy of rollformed profiles ensured compliance with stringent safety regulations.

Additionally, the energy sector, with a focus on renewable sources, has incorporated steel rollformed products for constructing supports and frames in solar power installations. These products provided stability and durability, vital for the long-term operation of solar farms.

Through such case studies, the adaptability and reliability of steel rollformed products are demonstrated in tangible terms. Their success across numerous projects solidifies rollforming's status as a key technique in modern manufacturing and construction.

Conclusion: The Future of Steel Rollformed Products in Industry

The utilization of steel rollformed products stands as a testament to the continuing evolution of industrial manufacturing and construction. As industries march toward a future where efficiency, precision, and sustainability become increasingly paramount, the role of rollforming is poised to expand even further.

The ongoing innovations in rollforming technology promise to deliver even greater efficiencies and capabilities. With improvements such as automation and advanced computer controls, manufacturers can look forward to faster production times, higher quality products, and more intricate designs that were once thought impossible.

Moreover, the shift towards sustainability will likely see steel rollforming playing a significant role in the production of eco-friendly and energy-efficient constructions. Its capacity to use materials more effectively and decrease waste aligns well with global initiatives to reduce the environmental impact of industrial activities.

As industries adopt more advanced materials and seek custom solutions for complex engineering challenges, the benefits of steel rollformed products will become even more prominent. The adaptability and resilience of rollforming will continue to support the needs of various sectors, enhancing the built environment and contributing to the advance of modern technology.

In conclusion, the future of steel rollformed products in industry is bright, marked by continual refinement of the process and heightened demand for the unique qualities these products provide. Rollforming stands to remain an integral process in meeting the demands of tomorrow's world, driving innovation and sustaining progress across multiple platforms.

Exploring the Potential of Rollformed Steel

What are steel rollformed products used for in construction?

Steel rollformed products are used in construction for a variety of applications, including structural components such as frames, beams, and roofing panels due to their high strength and stability. They also serve architectural purposes in forming aesthetic details and finishes for buildings.

How does rollforming compare to other steel shaping processes?

Rollforming is a continuous bending operation in which steel is passed through a series of rolls, each performing a part of the bend until the final shape is achieved. This process is highly efficient for producing uniform, precise profiles and lends itself to high production rates with minimal material waste, unlike processes such as extrusion or machining.

What materials can be used in the rollforming process?

Various types of steel, such as cold-rolled, hot-rolled, high-strength, and stainless steel, can be used in the rollforming process. Each material type is chosen based on the specific requirements of the application, such as finish, strength, or corrosion resistance.

Can rollformed steel products be customized?

Yes, one of the advantages of rollforming is the ability to customize steel profiles to meet specific dimensions and design requirements. The process allows for the creation of complex cross-sections and integrates additional features such as embossed patterns or precision cutouts.

What are the sustainability benefits of rollformed steel products?

Rollformed steel products contribute to sustainability through efficient material use and minimal waste production. Steel is a highly recyclable material, and rollforming supports the circular economy model. Advanced machine designs and energy-efficient practices further augment the eco-friendliness of this manufacturing process.