Table of Contents:

The Dawn of Modern Steel Production

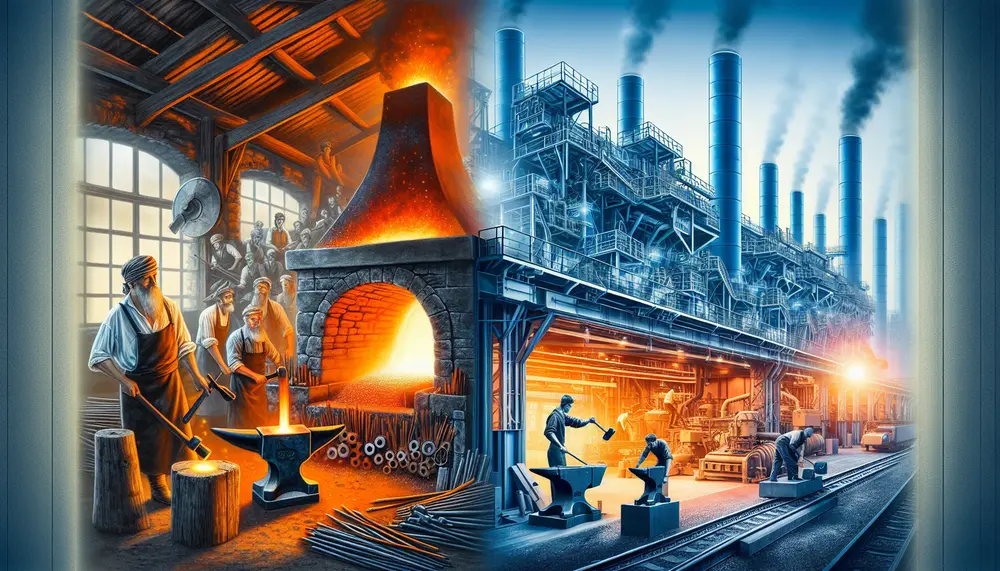

The story of steel production is a tale of human ingenuity and relentless progress. At the dawn of the 20th century, steelmaking was an arduous and labor-intensive process. The Bessemer Process, invented in the 1850s, had revolutionized the industry by introducing a method for mass-producing steel from pig iron. However, it was soon replaced by the Open Hearth Process, which became the preferred technique at the start of the modern era.

During the early days of modern steel production, the Open Hearth Process dominated the industry. Using large open furnaces, this method allowed for greater control over the quality of steel, though it was a rather slow process, requiring several hours to produce one heat of steel. As the 20th century advanced, changes were on the horizon that would not only speed up production but also improve the quality and types of steel available.

It was also around this time that the electric arc furnace (EAF) began gaining in prominence. Though initially used for small-scale production due to the cost of electricity, by mid-century, EAFs became more widely adopted as they allowed for the use of scrap metal as feedstock, thus laying the foundation for modern steel recycling practices.

The introduction of the Basic Oxygen Steelmaking (BOS) process in the 1950s represented another significant leap forward. The BOS process drastically reduced the time required to convert molten iron into steel, further increasing production efficiency and solidifying steel's position as the backbone of modern industry and infrastructure.

"The 20th-century advancements in steel production have set the stage for the high-tech, efficient practices we see today. The journey from open hearth furnaces to the Basic Oxygen Steelmaking process embodies the innovation and adaptability of the industry."

Evolution of Steelmaking: From Open Hearth to Electric Arc Furnaces

The evolution of steel production techniques over the last century is marked by a transition from labor-intensive processes to high-tech operations. The shift from the Open Hearth method to Electric Arc Furnace (EAF) technology stands as a prime example of this transformation. While Open Hearth furnaces relied on the combustion of coal or natural gas to reach the high temperatures necessary for steel production, EAFs leveraged electrical energy.

The migration to EAFs was propelled by several critical advantages. Chief among these was the ability to use scrap metal as a primary feedstock, effectively making steel production more sustainable and cost-effective. This change mirrored the broader societal shift towards environmental consciousness and resource efficiency.

Another significant improvement associated with EAF technology is the reduction in production time. EAFs can melt scrap and produce steel in significantly less time compared to the many hours an Open Hearth furnace required. Additionally, the process lent itself to better control over the steel's chemical composition, allowing for the production of specialized steel grades.

Furthermore, EAFs have undergone continual enhancements, including the use of ultra-high-power transformers, which increase melting efficiency, and the integration of computerized control systems that provide precision and repeatability in production. These advancements have made EAFs a cornerstone of modern steelmaking technology.

"Electric Arc Furnaces represent the pinnacle of efficiency and agility in the steel industry's evolution, marking a stark departure from the protracted procedures of the past to meet the demands of the present and future."

Evolution of Steel Production Techniques Over the Century

| Aspect | 100 Years Ago | Present |

|---|---|---|

| Production Volume | Relatively Low | Massively Scaled Up |

| Technology | Basic Blast Furnaces | Advanced Electric Arc Furnaces, Continuous Casting |

| Energy Consumption | High | Drastically Reduced |

| Environmental Impact | Significant Pollution | More Environmentally Conscious, Emission Controls |

| Labor Conditions | Often Harsh and Unsafe | Improved Safety and Regulation |

| Product Quality | Standardized Grades | Highly Specialized Alloys and Grades |

| Automation | Minimal | Extensive Automation and Control Systems |

| Material Efficiency | Wasteful | Optimized with Less Waste |

Major Milestones in Steel Production Over the Last Century

As we trace the arc of steel production milestones from the past century, we witness a timeline of innovation that has profoundly revolutionized the industry. Each milestone is a testament to how the sector has responded to the needs of a changing world with agility and profound engineering insights.

- The Basic Oxygen Steelmaking Process (BOS) in the 1950s drastically trimmed steel production times and scaled up output, marking a revolution in industrial efficiency.

- The development of continuous casting in the 1960s allowed for the direct casting of steel into solid shapes, bypassing intermediary steps and saving both time and energy.

- In the 1980s, the integration of computer technology gave rise to automation and precision in steelmaking, paving the way for consistent quality and repeatable processes.

- The late 20th and early 21st centuries saw the advent of advanced high-strength steels (AHSS), with applications from automobile manufacturing to construction, reflecting the industry's focus on performance and safety.

- The turn of the millennium was marked by the embrace of sustainability and recycling, with the steel industry becoming a world leader in recycling efforts and energy conservation.

Each of these milestones has not only advanced the productivity and efficiency of steel production but has also worked to address the growing demands for environmental stewardship and the efficient use of resources. These developments reflect a dynamic industry that is poised to meet future challenges with the same innovative spirit that has defined the last hundred years.

"The last century of steel production is a rich tapestry of breakthroughs, reflecting a relentless quest not just for industrial growth but also for innovation that honors our collective responsibility to the environment and society."

Technological Innovations Shaping Today's Steel Industry

Technological innovations continue to shape the steel industry, driving it towards greater heights of efficiency and sustainability. In recent years, a number of groundbreaking advancements have emerged, each contributing to an industry that is more modern, adaptive, and eco-friendly than ever before.

- Smart Manufacturing: Leveraging the power of the Internet of Things (IoT), smart manufacturing has introduced a new layer of intelligence to steel production, with real-time data analytics and predictive maintenance models decreasing downtime and increasing productivity.

- Use of Alternative Energy Sources: Steel mills are increasingly turning to renewable energy sources, such as solar and wind power, reducing their reliance on fossil fuels and their carbon footprint.

- Carbon Capture and Storage (CCS): As the industry seeks to minimize its environmental impact, CCS technologies allow for the capture of carbon emissions from steel production, preventing them from entering the atmosphere.

- 3D Printing: Additive manufacturing, or 3D printing with metal, enables the direct fabrication of complex steel parts, potentially reducing waste and accelerating the production process.

These technologies not only represent the cutting edge of steel production but are also indicative of a broader shift within the industry towards innovation that delivers economic value while being mindful of environmental and societal impacts.

"Modern technology is the driving force behind today's steel industry, providing the tools to rise to the demands of a planet that necessitates smart, sustainable, and adaptable solutions."

The Rise of Mini-Mills and the Decline of Traditional Steel Giants

The landscape of the steel industry has undergone considerable changes with the rise of mini-mills and the decline of traditional steel giants. This shift has reshaped steel production dynamics and has had profound implications for the market and for communities around the world.

Mini-mills, as agile and compact steelmaking facilities, rely heavily on Electric Arc Furnaces (EAFs) and recycled scrap to produce steel. They have significantly lower initial capital costs compared to traditional integrated steel mills and offer a high level of flexibility in operation, making them capable of quickly adjusting to market fluctuations.

This new breed of steel mills has been gaining a competitive edge in certain segments of the market, particularly in the production of long steel products like rebar and structural sections. Their proliferation has brought production closer to local markets, reducing transportation costs and associated carbon emissions.

Conversely, traditional steel giants, with their massive blast furnaces and extensive infrastructure, have faced challenges adapting to the rapid changes in demand and the increased competitiveness of mini-mills. The high cost of maintaining and modernizing these large-scale operations has led to a gradual decline in their prevalence and dominance.

"Mini-mills are rewriting the playbook of the steel industry, offering a nimble and environmentally friendlier approach to steelmaking that stands in contrast to the slower adaptation seen within the ranks of traditional steel giants."

Environmental Impact and Sustainability in Steel Production

As global awareness of environmental issues has risen, the steel industry has increasingly focused on minimizing its environmental footprint. This commitment to sustainability is evident in numerous initiatives and innovative production methods that aim to reduce emissions and conserve resources.

- Energy Efficient Technologies: Advances such as Co-generation power plants within steel facilities convert excess heat to electricity, markedly cutting down on energy waste.

- Waste Management Practices: The industry has implemented comprehensive strategies to repurpose by-products from the production process, thus reducing waste and promoting circular economy principles.

- Green Steel: Efforts to produce so-called 'green steel' involve methods that emit less carbon by incorporating hydrogen reduction processes, thereby setting the stage for a cleaner production cycle.

- Eco-friendly Material Sourcing: The shift towards sourcing raw materials from responsible suppliers who adhere to environmental standards is another stride towards sustainable steel production.

These transformative practices not only mitigate the impact of steel production on the environment but also ensure that the industry remains viable and competitive in an increasingly eco-conscious market.

"The drive towards environmental responsibility in steel production is a vital pivot for the industry, showcasing a readiness to innovate and optimize in pursuit of a more sustainable future."

The Role of Automation and AI in Modern Steel Manufacturing

The integration of automation and artificial intelligence (AI) into steel manufacturing has been a game-changer, significantly altering the way steel is produced, monitored, and delivered. This sophisticated interplay of technology ensures consistently high-quality products and propels the industry forward into a new era of efficiency and innovation.

- Advanced Monitoring Systems: Real-time monitoring and control systems powered by AI have enabled steel manufacturers to detect and correct process deviations, predicting maintenance needs before they result in downtime.

- Optimized Production Flows: Through machine learning algorithms, steel manufacturing processes are continually analyzed and improved, streamlining operations and reducing materials waste.

- Robotic Automation: Robotic arms and other automated machinery have taken over labor-intensive tasks, leading to safer factories with reduced human error and increased production speed.

- Supply Chain Management: AI algorithms help in forecasting demand and managing inventory, aligning production schedules with market needs and thus enhancing the overall supply chain efficiency.

The deployment of automation and AI technologies marks a profound shift from traditional manual operation to advanced manufacturing, setting the stage for smarter, safer, and more sustainable steel production strategies.

"Automation and artificial intelligence are not just modern conveniences—they are pivotal tools that are reshaping the entire steel manufacturing landscape, heralding an age of precision and intelligent production."

Global Shifts: How Geopolitics Has Reshaped Steel Production

Geopolitics has long been a critical factor in the global economy, and the steel industry is no exception. Over the past century, political decisions, trade agreements, and international relations have significantly influenced the production and distribution of steel on a global scale.

- Trade Policies and Tariffs: The implementation of tariffs and trade policies has periodically altered the competitive landscape, influencing where and how steel is produced and sold.

- Regional Alliances: Economic alliances between countries can lead to shifts in production capacities, as manufacturers may relocate to take advantage of favorable trade terms or economic policies.

- Access to Raw Materials: Political stability and control over natural resources like iron ore and coking coal dictate a country's ability to produce steel competitively, swaying the balance of global production.

- Infrastructure Investments: Governmental investments in infrastructure can stimulate demand for steel, influencing the scale and locale of production to meet these enlarged requirements.

These geopolitical dynamics have profound implications for the steel industry, driving investment, innovation, and competition. They necessitate agile and strategic responses from steel producers to adapt to an ever-changing geopolitical landscape.

"The nexus of geopolitics and steel production is a complex interplay of economic and political forces that continue to redefine the contours of the industry at both local and global levels."

Future Trends: The Next Frontier in Steel Production Techniques

As the steel industry looks to the future, a new frontier of production techniques is emerging, with innovations that promise to redefine the standards for efficiency, quality, and sustainability. These pioneering methodologies carry the potential to revolutionize steel production for future generations.

- Hydrogen-Based Steelmaking: With the aim of reducing carbon emissions, the industry is exploring the use of hydrogen as a replacement for carbon in the reduction of iron ore, heralding a potential leap towards 'zero-carbon steel'.

- Nanotechnology: Incorporating nanomaterials into steel production could lead to the creation of steels with unprecedented strength and flexibility, opening up new applications and advancing material sciences.

- Process Digitization: The full digitization of steel manufacturing processes is set to further enhance precision and efficiency, leveraging data analytics and interconnected machinery to new extents.

- Urban Mining: As a more sustainable approach to sourcing materials, 'urban mining' seeks to reclaim and recycle metals from urban environments, reducing the need for virgin ore mining.

These anticipated trends are part of a broader, transformative vision for steel production that aligns with global priorities of sustainability and technological progress. As steel continues to be a cornerstone of industrial development, these advancements will play a crucial role in its ongoing evolution.

"The next frontier in steel production techniques is not just a horizon of technological advancements; it's a commitment to innovation that anticipates the needs of both the planet and industry."

Understanding the Economic Impact of Steel Production Evolution

The transformation of steel production over the past century has had a profound economic impact, not only within the steel industry itself but also across the global economy. The evolution of steelmaking has driven growth, fostered innovation, and has been a bellwether for industrial vitality.

Increased Efficiency and Reduced Costs: Technological advancements in steel production have streamlined operations, leading to cost reductions that benefit end-users in industries such as construction, automotive, and appliance manufacturing.

Job Creation and Shifts: The advancement of steel production techniques has altered the workforce landscape, creating new jobs in advanced technology sectors while reducing reliance on traditional labor-intensive roles.

Global Trade Patterns: Innovations in production have influenced trade patterns, with emerging economies becoming significant steel producers and consumers, thus affecting global supply chains and market competitiveness.

Industrial Development: The continuous improvement in steel production has been a catalyst for industrial development, supporting the growth of related sectors and facilitating infrastructure improvements worldwide.

Overall, the evolution of steel production has been a significant economic driver, shaping the fortunes of industries and nations alike. The challenge for the future will be to ensure that this economic impact is balanced with social and environmental responsibility.

"The economic narrative of steel production is one of transformative influence—a journey that has catalyzed industrial expansion and economic diversification on a global scale."

Steel Recycling: Closing the Loop on a Century of Innovation

Steel recycling stands as a crucial component of the industry's innovation cycle, demonstrating a commitment to environmental stewardship and resource efficiency. Closing the loop on production, steel recycling creates a sustainable path forward, ensuring that the material remains a part of the economic fabric without depleting natural resources.

Energy Conservation: Recycling steel saves energy compared to producing steel from virgin materials, markedly diminishing the overall energy demand of the industry and lowering greenhouse gas emissions.

Resource Management: The inherent recyclability of steel prevents the depletion of iron ore resources, ensuring that steel can be continuously reused without loss of quality or performance.

Economic Advantage: The recycling industry adds economic value by recovering scrap and reducing costs associated with waste management and raw material extraction.

Innovation in Recycling Technology: New methods and technologies in the recycling of steel continually emerge, improving the efficiency and effectiveness of the recycling process and further optimizing the industry's environmental performance.

Steel recycling is not merely a process—it is an emblem of sustainable practices woven into the very industry it serves, highlighting a century-long pursuit of innovation that goes hand in hand with ecological awareness.

"Steel recycling encapsulates a modern industrial ethos, one that respects the past, harnesses the present, and safeguards the future through intelligent, sustainable action."

The Human Factor: Employment Changes in the Steel Industry Over Time

The steel industry has been a major employer for over a century, but the nature of employment within the industry has undergone significant changes parallel to the evolution of steel production techniques. As the industry has modernized, the human factor has adapted in response to these advancements.

Labor Requirements Shift: The increased automation and digitization in steel production have led to a decrease in labor-intensive roles but have created new opportunities in the field of engineering, technology, and management.

Workforce Training and Development: With the advent of advanced technologies, ongoing training and skill development have become essential for the steel industry's workforce to stay current with the ever-evolving production landscape.

Health and Safety Improvements: Technological advancements have also contributed to a safer work environment, reducing the risk of injuries and improving the overall wellbeing of employees.

The steel industry's employment landscape will continue to evolve, shaped by innovation and economic forces. The human element remains a vital aspect of the industry, with an increasing focus on a skilled and knowledgeable workforce ready to meet the challenges of modern steel production.

"While technology has reshaped the steel industry in profound ways, it is the adaptability and ingenuity of its workforce that continue to drive it forward."

Steel Quality and Variety: How Production Techniques Have Enhanced Performance

Over the last century, the evolution of steel production techniques has not just been about quantity and speed; it has significantly influenced the quality and variety of steel available on the market. Advanced production processes have allowed for the development of a multitude of steel grades, each tailored to specific applications and performance requirements.

Enhanced Material Properties: Technological progress has enabled precise control over alloying elements, leading to improvements in steel's strength, ductility, and corrosion resistance.

Specialized Steel Types: Innovations in production have resulted in specialized types of steel, such as electrical, stainless, and tool steels, vastly expanding the applications of this versatile material.

Consistency and Uniformity: Modern production techniques ensure greater consistency and uniformity in steel products, which is crucial for critical applications in construction, transportation, and infrastructure.

The continuous enhancement of steel performance through advanced production techniques has made it an indispensable material in modern society, fulfilling roles that are as diverse as the steel varieties themselves.

"The sophistication of today's steel quality and the breadth of its variety are direct reflections of the century-long march of progress in production techniques."

Energy Efficiency and Emission Reductions in Steel Production History

The history of steel production is marked by not only technological advances but also by a growing emphasis on energy efficiency and emission reductions. As environmental concerns have gained prominence, the steel industry has responded by implementing measures to lower its energy consumption and reduce its carbon footprint.

Improvements in Energy Consumption: Through the adoption of new technologies and processes, steel producers have significantly lowered their energy requirements, leading to more sustainable manufacturing practices.

Innovations in Emission Control: Development of cleaner production methods, such as direct reduced iron (DRI) and near-zero emission steelmaking facilities, demonstrate the industry's commitment to reducing environmental impact.

Focused Industry Standards: The implementation of industry-wide standards and benchmarks for energy consumption and emissions has propelled steel producers to pursue continuous improvements and share best practices.

The historical trend towards greater energy efficiency and reduced emissions represents a positive trajectory for the steel industry, aligning it with global efforts to combat climate change and preserve environmental quality.

"From energy-intensive beginnings to the current pursuit of sustainability, the steel industry's history of improving energy efficiency and reducing emissions is a proactive testament to its role in a greener future."

The Steel Production Legacy: A Look Back at 100 Years of Progress

Reflecting on the legacy of steel production over the last century reveals a remarkable journey of industrial evolution and growth. This century of progress has transformed the way steel is made, employed, and experienced in everyday life.

Key Developments in Production Processes: Advancements such as the transition from basic open hearth furnaces to sophisticated electric arc furnace technology have redefined production efficacy and environmental impact.

The Emergence of Steel as a Global Commodity: Steel has risen to become a staple of the world's economic and infrastructural development, underlying advancements in sectors ranging from transportation to architecture.

Contributions to Societal Well-Being: The steel industry's evolution has been integral to improving quality of life globally, with its products forming the backbone of modern civilization's physical framework.

The past 100 years have seen steel production mature from a burgeoning industry into a cornerstone of modern society, setting the stage for continuing innovation and progress in the century to come.

"A century of progress in steel production has not only forged materials but has also shaped economies, fostered innovations, and constructed the edifice of contemporary life."

FAQ: A Century's Evolution of Steel Production Methods

What revolutionized steel production in the 20th century?

The introduction of the Basic Oxygen Steelmaking (BOS) process in the 1950s revolutionized steel production. It drastically reduced the time to convert molten iron into steel, increased efficiency, and set new standards for production speed and scale.

How did the Electric Arc Furnace (EAF) transform steel recycling?

EAF technology allowed for the use of scrap metal as a primary feedstock, greatly increasing the sustainability of steel production. It also significantly reduced the energy consumption and production time compared to previous methods, such as the Open Hearth furnaces.

How has automation influenced the steel industry?

Automation has significantly changed the steel industry by reducing reliance on human labor, increasing production speeds, improving safety, and achieving better quality and consistency in steel products.

What role does Artificial Intelligence (AI) play in modern steel manufacturing?

AI plays a pivotal role in modern steel manufacturing by enhancing monitoring and control systems, optimizing production flows, improving supply chain management, and enabling predictive maintenance, resulting in more efficient and intelligent production processes.

What are the environmental impacts of the changes in steel production techniques over the past century?

The evolution of steel production techniques has led to significant improvements in energy efficiency and reduction in emissions. Technologies such as EAFs and continuous casting have lowered the industry's carbon footprint, and initiatives in recycling have further advanced its environmental stewardship.