Table of Contents:

Introduction to Indian Steel Excellence

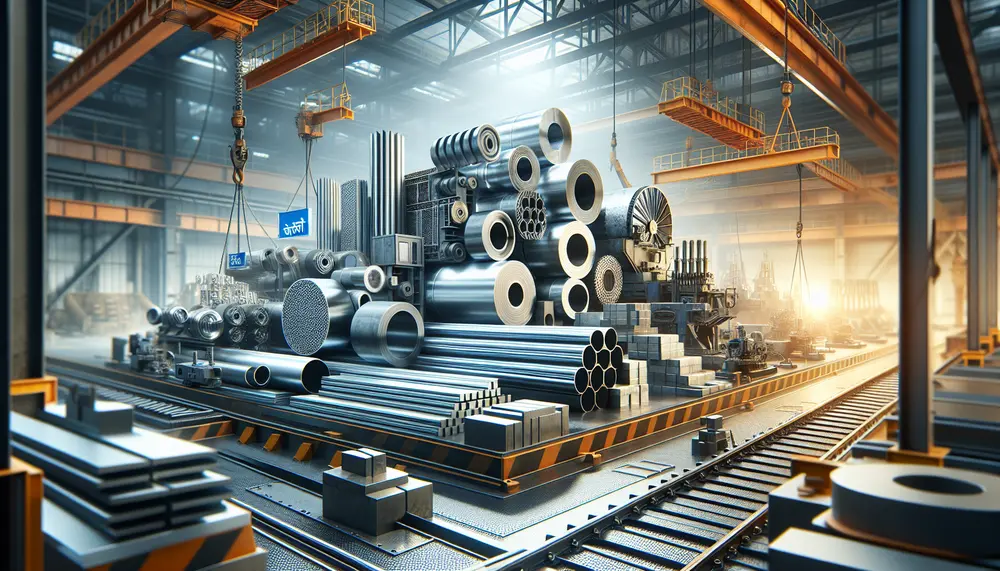

The realm of steel production has seen India emerge as a global powerhouse, with the country's expansive growth in the industry marking it as a focal point for both quality and innovation. Indian steel has not just carved a niche in terms of volume but has also garnered recognition for its superior quality. This introduction delves into the factors that contribute to the excellence of steel products from India, highlighting how the confluence of rich historical expertise, modern advancements, and robust policy support shapes a dynamic and progressive steel industry.

The Rise of India's Steel Industry

The journey of India's steel industry is a narrative of strategic growth and adaptation. Following its deregulation in the early 90s, the sector has witnessed unprecedented expansion, evolving from humble beginnings to becoming a world leader in steel production. This growth trajectory is accredited to a mix of visionary policies, technological enhancements, and a firm commitment to meet both domestic and international demand.

India's rapid industrialization provided fertile ground for the steel sector's development, turning it into a bedrock for the nation's infrastructure projects. It was this fertile environment that catalyzed the establishment of numerous mini and integrated steel plants, driving competition and fostering a climate conducive to innovation.

No longer bound by stringent controls, Indian steel manufacturers have soared, benefiting greatly from the National Steel Policy's framework which set ambitious production targets. This policy laid down the groundwork for a modernized steel industry, well-equipped to handle the challenges of the new millennium.

Benefits and Drawbacks of Indian Steel Products

| Pros | Cons |

|---|---|

| High-quality steel production | Inconsistency in quality across different manufacturers |

| Cost-effective manufacturing processes | Perception of lower quality compared to other countries |

| Innovative industry practices | Competition from established steel industries globally |

| Increasing exports year-over-year | Transportation and logistics challenges |

| Strong domestic market growth | Potential trade restrictions or tariffs |

Key Players in the Indian Steel Market

Within the robust framework of India's steel industry, several key players stand out, each contributing significantly to the sector's dynamism and reputation for excellence. Companies such as JSW Steel, with its substantial production capacity and recognition for workplace quality, underscore the competitive spirit of the market.

This landscape of heavyweights is diversified with strategic collaborations, like that between JSW Steel and Japan's JFE Steel, which meld international expertise with Indian innovation. Furthermore, accolades such as the Steel Sustainability Champion award and sustainability indices have put Indian steel giants on the global map for not just their production scale but also their commitment to sustainable practices.

- JSW Steel - Known for innovation and sustainability

- Tata Steel - One of the oldest and most significant contributors to the market

- Steel Authority of India Ltd (SAIL) - A public sector powerhouse

- Essar Steel - A modern and versatile steel producer

These companies depict the industry's focus on quality, environmental responsibility, and innovation, which are hallmarks of steel products from India. With their expansive facilities, such as JSW Steel's notable plant in Vijayanagar, and an array of international certifications, Indian steel manufacturers are a testament to the sector's global stature and promise.

Innovations in Indian Steel Production

The Indian steel industry, remarkable for its scale and quality, is equally renowned for its innovative production techniques. Embracing the future, Indian steel companies are investing in cutting-edge technologies to enhance efficiency and minimize environmental impact. The fusion of traditional knowledge and modern science has led to the production of advanced steel grades and high-performance products that cater to a variety of sectors.

Advancements such as the implementation of the state-of-the-art continuous casting process have enabled producers to attain higher standards of product uniformity and integrity. Moreover, the introduction of blast furnace models that optimize fuel efficiency has proven to be a groundbreaking step toward sustainably fulfilling the growing steel demand.

Automation and digitization have also played a crucial role in the industry's innovation curve. Smart factories utilizing artificial intelligence and machine learning are streamlining production processes, ensuring precision, and facilitating predictive maintenance to avoid unplanned downtimes, thus propelling the Indian steel segment to new heights of global competitiveness.

Moreover, research and development initiatives are in full swing, with industry leaders investing heavily in laboratories and collaborations with academic institutions to pave the path for the next generation of steel products. These innovations not only enhance the steel products from India but also reinforce the sector's adaptability to future challenges and opportunities.

Quality and Standards of Indian Steel Products

Integral to the reputation of steel products from India is their unwavering adherence to stringent quality benchmarks and standards. Indian steel manufacturers operate under the ethos of 'quality first', a principle that is instilled across all stages of production, from raw material selection to the final product delivery.

Compliance with international standards such as ISO and ASTM is not just a regulatory mandate but a business imperative for Indian steel companies. Rigorous quality control measures and regular audits ensure that products meet and often exceed these global benchmarks, reassuring customers of the reliability and durability of Indian steel.

Moreover, certifications such as the Bureau of Indian Standards (BIS) hallmark serve as a testament to the quality of Indian steel, signalling to the world that products bearing this mark meet the highest criteria of production excellence. This attention to detail and focus on superior quality control has made Indian steel synonymous with trust and dependability in the international market.

"Quality is the cornerstone of success in the global steel trade, and this is a philosophy that Indian steel producers have adopted fully to meet the rigorous demands of both domestic and worldwide customers."

The Diversity of Steel Products from India

The Indian steel sector is distinguished by its extensive array of products, each tailored to meet the demands of various industries. From construction beams to automotive parts, the versatility of steel products from India is a clear reflection of the industry's capability to innovate and customize as per client specifications.

High-grade alloy steels and stainless steels form a significant portion of the product range, known for their strength and resistance to corrosion, making them ideal for use in aggressive environments. Flat and long steel products, coated sheets, and specialty bars are more examples of the diversity that Indian producers bring to the global market.

- Flat products for automotive and home appliance manufacturing

- Long products used in construction and infrastructure

- Stainless steel for utensils and medical instruments

- Alloy steels for precision tools and high-stress applications

This diverse product portfolio is not only a testament to the versatility of steel products from India but also highlights the industry's keen understanding of market needs. Whether for everyday applications or specialized industries, the Indian steel sector is adept at offering customized solutions that drive progress and efficiency.

Environmental Sustainability in Indian Steel Manufacturing

Environmental sustainability is a central tenet in the operation of the Indian steel industry, reflecting a deep-seated commitment to responsible manufacturing. Recognizing the need for eco-friendly practices, Indian steel producers have implemented measures to reduce their carbon footprint and conserve resources throughout the production process.

Innovative methods such as using greener energy sources and recycling water in cooling systems demonstrate the proactive steps taken towards minimizing environmental impact. The adoption of by-product gas for power generation has also greatly contributed to enhanced energy efficiency and reduced emissions.

Indian steel companies are making substantial investments in research to develop new technologies that can further drive down emissions and waste. The commitment to such sustainable practices is not only a moral duty but also an economic strategy, as they look to future-proof their operations against a backdrop of increasing environmental regulations.

"As global attention shifts towards sustainability, the Indian steel industry is paving the way by integrating eco-conscious strategies that align with worldly aspirations for a cleaner, greener future."

Exporting Indian Steel: Global Impact and Reach

The global steel marketplace is witnessing the expanding influence of Indian steel products, making them a preferred choice for importers around the world. The strategic export of Indian steel is bolstered by its recognizable quality, an expansive product range, and the versatility to cater to industry-specific needs.

Foreign markets benefit from India's robust steel output, which includes specialty products that are often hard to find elsewhere. The reputation for reliability and strength in Indian steel has led to its increased presence in international construction projects, automobile manufacturing, and infrastructure development.

Moreover, the adaptability of Indian steel manufacturers to meet different international norms and standards ensures that steel products from India are compatible with global market requirements. This alignment with international quality standards has opened doors to new markets, fostering long-term trade relationships.

"The export of Indian steel products is a testament to the sector's global competitiveness and its ability to influence and integrate within international supply chains."

Challenges and Opportunities for Indian Steel Producers

Indian steel producers navigate a landscape filled with both challenges and opportunities. On one hand, global economic fluctuations, trade protectionism, and the volatility of raw material costs pose significant hurdles. On the other hand, the growing infrastructure demands within India and emerging markets abroad present substantial openings for expansion and growth.

In response to these challenges, steel manufacturers in India are investing in process optimizations, supply chain diversifications, and market expansions. Tariff barriers and trade policies compel a strategic reassessment and prompt Indian steel producers to explore untapped markets and strengthen existing trade ties.

The opportunity to supply steel for smart city projects, renewable energy structures, and next-generation transportation systems highlights the sector's potential for substantial growth. Further, evolving technology and the global push toward sustainable practices drive Indian steel producers to innovate and adopt green manufacturing, creating a competitive edge in the eco-conscious market.

"While the challenges are real, so are the opportunities to fortify the Indian steel industry's global positioning through innovation, adaptability, and a forward-thinking approach."

Conclusion: The Future of Steel Products from India

As we reflect on the journey and accomplishments of the Indian steel industry, it is clear that the future shines bright for steel products from India. Marrying a rich history in metallurgy with contemporary advancements, Indian steel producers are well-positioned to continue their trajectory of growth and influence within the global market.

The relentless pursuit of innovation, commitment to quality, and increasing focus on sustainability are set to further enhance the appeal and competitiveness of Indian steel products. Moving forward, continued investments in technology, along with strategic market expansion, will likely ensure that India remains at the forefront of the steel production industry.

With a firm foundation and a vision aligned with global trends and needs, the potential for Indian steel to meet the demands of an ever-changing world is immense. The steadfast path that Indian steel producers have carved out promises resilience, adaptability, and significant contributions to the global steel landscape in the years to come.

"Steel products from India are poised for a dynamic global impact, with the ability to shape industry standards and drive innovation across borders."

Essential FAQs on Indian Steel Manufacturing Prowess

What makes Indian steel products globally competitive?

Indian steel products are known for their high quality, cost-effective manufacturing, innovative practices, and commitment to sustainability. Strategic collaborations, such as JSW Steel's partnership with JFE Steel, also enhance India's competitiveness in the global steel market.

How have modern advancements impacted Indian steel production?

Modern advancements, including the adoption of continuous casting processes, optimizations in blast furnace technology, and digitization have improved efficiency, quality, and sustainability in Indian steel production, raising standards to meet global demands.

What are the key sustainability practices in Indian steel manufacturing?

Indian steel manufacturers are focusing on reducing carbon emissions, increasing energy efficiency, and implementing recycling practices. Use of by-product gas for power generation and greener energy sources are examples of their commitment to environmental sustainability.

Can Indian steel products meet international quality standards?

Yes, Indian steel manufacturers adhere to stringent international quality standards, with compliance to ISO and ASTM benchmarks, rigorous quality control measures, and certifications like the Bureau of Indian Standards (BIS) hallmark ensuring their products are globally trusted.

What range of steel products does India offer to the global market?

India offers a diverse range of steel products including high-grade alloy steels, stainless steels, flat products for automotive and appliances, long products for construction, and specialty bars, catering to a wide variety of industrial needs.