Table of Contents:

Introduction to Steel Products in Various Industries

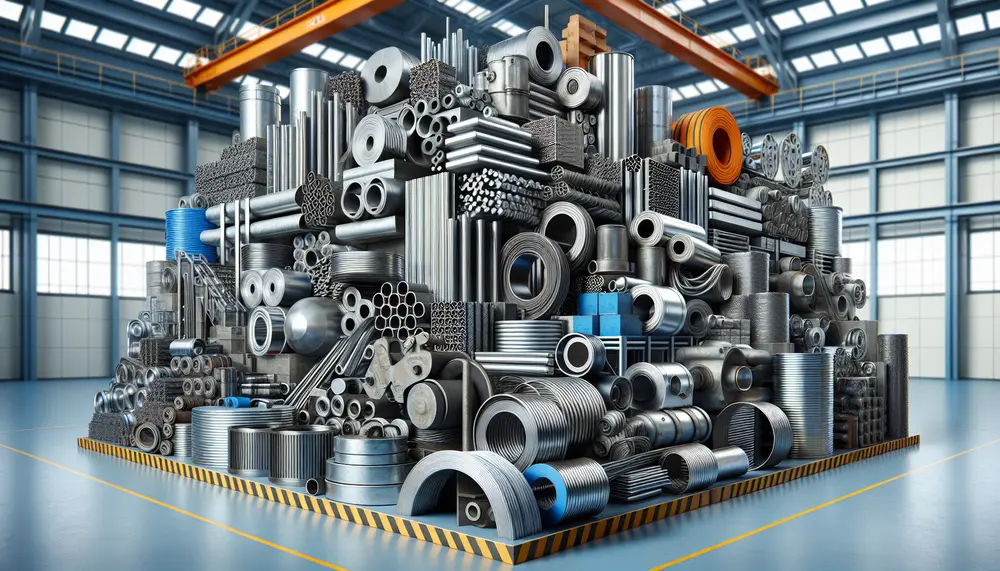

Welcome to our comprehensive exploration of steel products, the backbone of modern industry. Steel, known for its strength and versatility, plays a crucial role across various sectors. From construction to electronics, automotive to appliances, the applications of steel are as diverse as the industries themselves. This article aims to unveil the essential steel products widely used in different industries, illustrating their significance and offering a practical guide to understanding the vast world of steel. Whether you're a seasoned professional or new to the steel trade, this overview will equip you with the insights needed to navigate the steel products list effectively.

Understanding the Basics of Steel Production

Before delving into the specifics of steel products, it's important to grasp the fundamentals of steel production. This process transforms raw materials, primarily iron ore and coal, into the steel used in countless applications. There are two main production methods: Blast Furnace-Basic Oxygen Furnace (BF-BOF) and Electric Arc Furnace (EAF). The former involves reducing iron ore into molten iron and then refining it into steel, while the latter recycles scrap steel using high-power electric arcs. Understanding these methods is key to recognizing the quality, characteristics, and sustainability of different steel products, which ultimately influences their suitability for various applications.

Comparative Analysis of Steel Applications in Various Industries

| Industry | Essential Steel Products | Pros | Cons |

|---|---|---|---|

| Construction | Rebar, Structural Beams, Steel Plates | Durability, Support for Heavy Loads | Corrosion if not treated properly |

| Automotive | Steel Sheets, Stainless Steel Components | Strength, Safety in collisions | Heavier than alternative materials |

| Manufacturing | Machine Tools, Gears, Fasteners | High Precision, Resilience to Wear | Can be costly to produce |

| Energy | Pipelines, Structural Frames for Wind Turbines | Sustainability, Withstands Extreme Conditions | Requires regular maintenance |

| Medical | Surgical Instruments, Implants | Sterility, Biocompatibility | Specialized alloys can be expensive |

| Infrastructure | Bridges, Highways, Railroads | Longevity, Supports High Traffic Volumes | Infrastructure Ageing can lead to safety risks |

Key Steel Products and Their Applications

The steel industry offers a vast array of products each serving specialized and general purposes within different sectors. Among the key products is structural steel, utilized in the construction of buildings and bridges due to its high strength-to-weight ratio. Stainless steel is prized for its corrosion resistance, making it ideal for medical instruments and kitchenware. In transportation, automotive steel is essential in manufacturing safe and durable vehicle frames. Tool steel, another important category, includes high-speed and carbon varieties widely used in the production of cutting tools and molds. Each steel product exhibits unique properties and functionalities, providing engineers and designers the materials necessary to solve the most complex challenges across various industries.

Hot-Rolled vs. Cold-Rolled Steel: What's the Difference?

When selecting steel products for a project, one of the critical choices to make is between hot-rolled and cold-rolled steel, each with its own advantages and distinct manufacturing process. Hot-rolled steel is produced by rolling the steel at high temperatures, where it can be shaped and formed easily. This method results in steel with a rough surface texture and less precision in its dimensions. Conversely, cold-rolled steel refers to steel that is further processed at room temperature after hot rolling, leading to a smoother surface finish, greater dimensional accuracy, and enhanced strength due to work hardening. Understanding these differences is essential for choosing the right type of steel product for your industry-specific needs, ensuring both performance and cost-effectiveness.

Coated Steel Sheets: Enhancing Durability and Performance

In the realm of steel manufacturing, coated steel sheets stand out for their enhanced features. These sheets undergo a process where a protective layer is applied, providing additional resistance against corrosion, wear, and tear. Common types of coatings include zinc, aluminum, and silicone — each offering distinct benefits in terms of protection and durability. The application of coatings can also impart additional aesthetic qualities to the steel, such as color and texture, which can be crucial in consumer-facing products. The application of coated steel spreads across various industries, including automotive, where it’s used for body panels, and construction, for roofing and siding, providing long-lasting performance even in harsh environmental conditions.

Specialty Steel Products: Meeting Unique Industry Needs

Within the steel industry, specialty steel products are tailored to address the unique and demanding requirements of specific sectors. These products include varieties like stainless steel, tool steel, and electrical steel, each engineered to provide specific performance qualities. Stainless steel, for instance, is indispensable in sectors requiring rust resistance, such as medical and food-grade applications. Tool steel’s robustness makes it the preferred choice for high-strength tools and dies. Electrical steel's magnetic properties are critical for transformers and motors in the energy sector. By offering specialized characteristics such as heat resistance, hardness, or electrical conductivity, specialty steel products are essential for advancing technology and meeting the precise needs of modern industry.

The Role of Steel in the Automotive Industry

The importance of steel within the automotive industry is unparalleled, and it continues to be a material of choice due to its strength, affordability, and recyclability. Advanced high-strength steels (AHSS) are now integral in vehicle design, contributing to improved crashworthiness and overall vehicle safety without compromising on weight. This lightweight feature is particularly valuable for electric vehicles, where efficiency is paramount. Moreover, the innovations in steel processing have led to better formability and joining techniques, allowing for more complex vehicle designs. The automotive sector relies heavily on both hot-rolled and cold-rolled steels for different components, ranging from the structural integrity of the chassis to the finer cosmetic details of trim and finishes. Steel's adaptability continues to drive automotive innovation, sustaining its key role in an industry evolving towards more sustainable and safe transportation solutions.

Steel Solutions for Construction and Infrastructure

Construction and infrastructure projects form the framework of modern civilisation, and steel is a cornerstone material in this domain. Its ability to withstand tensile and compressive forces makes it perfect for reinforcing concrete in high-rise buildings, bridges, and tunnels. Steel's modular nature also supports prefabrication, which streamlines construction processes and reduces on-site waste. Galvanized steel, with its corrosion-resistant properties, is the material of choice for outdoor and exposed structures, ensuring longevity and durability. Steel piling supports the foundational aspects of construction, stabilizing soil in preparation for massive structures. In infrastructure, steel's flexibility allows for the expansion and contraction of highways and railways, critical under varying weather conditions. Its role in these industries is not just foundational but transformative, as steel products continue to evolve, offering smarter, safer, and more sustainable solutions for the spaces we inhabit.

Innovative Steel Materials for Electronics and Appliances

Innovative steel materials are a critical component in the world of electronics and appliances, where precision, durability, and electromagnetic properties are paramount. The electronics industry relies on steel for its magnetic properties, crucial in the manufacturing of components like transformers and inductors. For appliances, the aesthetic appeal of finished steel, coupled with its robustness, ensures that items such as refrigerators, ovens, and washers not only perform their functions effectively but also fit seamlessly into the modern home. With advancements in steel technology, including new alloy compositions and treatment processes, the material's conductivity, reflectivity, and resistance to heat and corrosion have been finely tuned to meet the exacting requirements of these industries. The continuous innovation in steel materials is paving the way for more energy-efficient, long-lasting and high-performing products in the consumer electronics and appliance markets.

The Importance of Steel in Packaging and Container Manufacturing

Steel's role in packaging and container manufacturing is pivotal due to its strength, malleability, and barrier properties. The packaging industry utilizes various forms of steel, such as tinplate and tin-free steel, for creating containers that protect food, beverages, and aerosols from contamination and spoilage. These steel types are valued for their non-toxicity, recyclability, and the ability to preserve the contents' flavor and freshness. In larger-scale container manufacturing, steel is the material of choice for shipping containers, which transport goods across the globe. Its resistance to harsh weather conditions and heavy loads makes it indispensable for maintaining the integrity of the world’s supply chains. The production of steel for packaging and containers demonstrates the material's versatility and adaptability, ensuring products remain safe, secure, and sustainable from factory to final destination.

Steel Pipes and Tubes: Supporting Energy and Utilities

Steel pipes and tubes form the circulatory system of the world's energy and utilities sectors. Essential for their rigidity and durability, these steel products facilitate the safe and efficient transport of resources like oil, gas, and water. Seamless steel tubing is particularly crucial in high-pressure applications such as underground oil wells, where failure is not an option. Within the utilities domain, large diameter pipes carry water to cities and communities, highlighting the material’s significance in sustaining modern life. Furthermore, steel conduits protect electrical wiring in both commercial and residential buildings, ensuring safety and reliability. The manufacturing precision of steel pipes and tubes is continually advancing, allowing for better performance even under the most demanding of conditions. Their importance in global infrastructure—powering our homes, fueling our vehicles, and delivering our water—can hardly be overstated.

Steel in Office Equipment: Strength and Aesthetics Combined

Steel plays an unexpected yet vital role in the realm of office equipment, balancing the need for strength with a demand for sleek, modern aesthetics. Its use in office furniture, such as desks and filing cabinets, speaks to steel's robust nature, capable of supporting significant weight and enduring the wear and tear of daily use. At the same time, steel's versatility allows it to be crafted into refined, stylish designs that contribute to a professional workspace ambiance. Beyond furniture, steel components are integral to the reliability and durability of office machinery, including printers, copiers, and safes. These applications benefit from steel's heat resistance and precision qualities, facilitating smooth operation and longevity. In an office environment, where functionality and design go hand in hand, steel proves to be an indispensable material.

Navigating the Steel Products List: Tips for Buyers

When faced with an extensive steel products list, buyers may find the selection process to be daunting. To efficiently navigate this diverse range, it's vital to focus on a few key considerations. First, understand the specific needs of your project or application, which will determine the type of steel product required. Consider whether you need structural strength, corrosion resistance, or perhaps a certain finish or coating. Second, factor in the dimensions and tolerances your application demands. Precision can be crucial, so clarify whether hot-rolled or cold-rolled steel is more appropriate. Third, assess the sustainability and recyclability of the steel, as environmental considerations become increasingly important. Lastly, seek out reputable suppliers who can provide quality certifications and have a transparent supply chain. These tips can guide buyers towards making informed, optimal choices from the steel products list, ensuring success in their respective projects.

Sustainability and Steel: Eco-Friendly Options

Amid growing environmental concerns, sustainability in steel production has become a pressing topic. The industry is making strides by adopting practices that reduce its carbon footprint and enhance efficiency. One of the key eco-friendly options is the use of electric arc furnace (EAF) technology, which largely relies on recycled materials and consumes less energy compared to traditional blast furnaces. Moreover, advancements in metallurgy have led to the development of high-strength steel grades that allow for thinner constructions without compromising integrity, thereby reducing material usage. Steel itself is inherently recyclable, and its magnetic properties make it easy to recover from waste streams for reuse in new products. By prioritizing sustainability, steel producers and consumers alike contribute to a circular economy, where steel's longevity and recyclability continually minimize its environmental impact.

Conclusion: The Integral Role of Steel Across Industries

In conclusion, the versatility of steel and its myriad of products remain integral to countless industries around the globe. From the structural integrity provided in construction to the nuanced applications in electronics, steel's role is both foundational and innovative. The advancements in steel production, including the development of high-strength and coated varieties, continue to push the frontiers of what is possible in manufacturing and design. Buyers, equipped with the knowledge of steel properties and applications, can make strategic choices that enhance the functionality and sustainability of their projects. As we look to the future, steel stands as a testament to human ingenuity—a material that has shaped our past and will continue to forge our path to a robust and sustainable future.

Key Steel Products for Industry Applications: FAQs

What are the primary types of steel used in construction?

In construction, the primary types of steel include rebar for reinforcement, structural beams for support, and steel plates for foundational and load-bearing tasks. These materials ensure durability and the ability to support heavy loads.

Why is stainless steel so important in the medical industry?

Stainless steel is crucial in the medical industry due to its sterility and biocompatibility. It does not react with bodily tissues and can be easily sterilized, making it perfect for surgical instruments, implants, and other medical devices.

How does coated steel enhance the automotive industry?

Coated steel provides extra protection against corrosion, extends the lifespan of vehicles, and can be used for aesthetic finishes. These coatings, such as zinc and aluminum, contribute to vehicle safety and longevity.

What role do steel pipes play in the energy sector?

Steel pipes are essential in the energy sector as they are used to transport oil, gas, and water. They are valued for their strength, which allows them to withstand high pressure and the rigors of transporting resources over long distances.

What are the advantages of using steel in packaging?

Steel offers high strength, barrier properties, and is easily recyclable, making it ideal for packaging. It keeps food and other perishables safe and extends their shelf life by protecting against contamination and spoilage.