Table of Contents:

Introduction to Steel Production Line

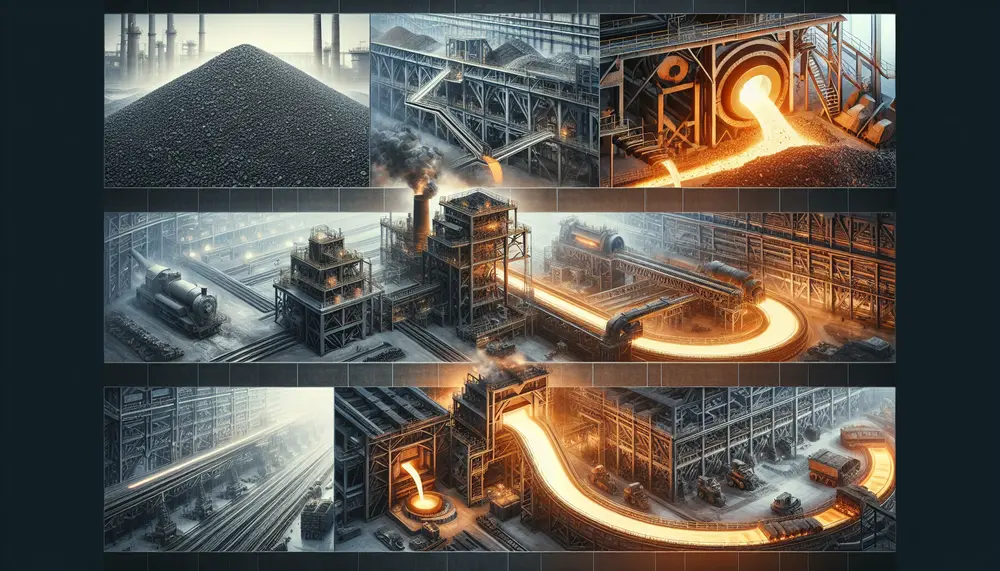

Welcome to the fascinating world of steel production. Steel, an alloy mainly composed of iron and a small amount of carbon, is one of the essential materials that shape our world. Whether it's skyscrapers, vehicles, railways, or everyday household items, steel's flexibility, stability, and durability make it an indispensable component of modern life.

In this article, we'll take a closer look at the process of transforming raw materials into the steel products we encounter every day. This journey, known as the steel production line, combines technology, chemistry, and engineering ingenuity. By understanding the steel production line, we can appreciate the efforts required to produce this versatile material and anticipate future trends in steel production.

Understanding the Basics of Steel Production

The production of steel is a meticulous process that requires accurate control and monitoring to ensure premium quality. The basic process involves transforming iron ore into steel using heat – a method adopted during the iron age itself. Yet, due to scientific advancements, it has evolved extensively over the years.

While there are alternative methods of producing steel, the most prevalent one is the Oxygen Steelmaking (BOS) process. This process commences with the production of raw iron, often called pig iron. Iron ore is mined and put through a reduction process to create this pig iron, which contains up to 4% carbon. This pig iron must then be purified to create steel, which has a maximum carbon content of 2%.

In the steelmaking phase, the pig iron is combined with scrap steel and subjected to high heat in a furnace. Oxygen is blown into the furnace to burn off excess carbon and other impurities, resulting in liquid steel.

Once the steel is produced, it is cast into forms known as billets, blooms, or slabs for further rolling and processing. A series of finishing operations like heat treatment are then performed to produce the final steel product.

It is critical to note that every stage of the steel production process is highly controlled and monitored to ensure high-quality steel that abides by various standards and specifications. This is where the steel production line's role comes into play.

Pros and Cons of the Steel Production Line

| Pros | Cons |

|---|---|

| Effective use of raw materials | High energy consumption |

| Large production quantities | Environmental pollution |

| Product versatility | Excessive carbon emissions |

| Industrial growth and economic benefits | Occupational hazards and safety concerns |

The Journey of Raw Materials in Steel Production

The transformative journey of raw materials into finished steel products starts with the extraction from the Earth's earth crust. Iron ore, limestone, and coke, a derivative of coal, are the main raw materials used in steel production.

Iron ores primarily consists of iron oxide compounds and are typically mined from open-pit mines. After mining, the iron ore undergoes several stages of treatment to reduce its size and increase its iron content. This culminates in a process called sintering that results in a hard, porous material known as sinter, ready to be used in the steelmaking process.

Simultaneously, limestone and coke are prepared. Limestone primarily acts as a flux to remove impurities during the steel manufacturing process, while coke, derived from coking coal, is a vital energy and reducing agent. It is heated in a series of coke ovens to remove impurities and produce a high-quality product.

The next stage sees these raw ingredients - sinter, coke, and limestone - entered into a Blast Furnace. Here, they are heated to incredibly high temperatures. This combination of heat and chemical reaction transforms these raw materials into molten pig iron and slag, a byproduct that's usually recycled for other purposes.

Finally, this hot metal, pig iron, is transferred to the basic oxygen furnace, where it is refined to produce steel. In this furnace, oxygen is blown through to reduce the carbon content, and fluxes are added to remove unwanted impurities and ensure the best quality steel. The process results in molten steel, which is then cast into the desired shapes for further processing and finishing.

Key Processes in the Steel Production Line

The steel production line involves multiple processes and procedures to ensure the transformation of raw materials to high-quality steel. However, some key stages form the backbone of this production line.

1. Ironmaking

The first step in the steel production line is ironmaking. As mentioned earlier, this introduces raw materials such as iron ore, coke, and limestone into a blast furnace. The materials undergo a reduction reaction, creating molten iron or pig iron, and slag as a by-product.

2. Steelmaking

This involves refining molten pig iron from the blast furnace into steel. Using a Basic Oxygen Furnace, oxygen is blasted to reduce impurities, primarily excess carbon. Steel with a controlled amount of carbon and other elements is produced.

3. Casting

The molten steel created in the previous process is now ready to be formed into recognisable preliminary forms. The steel is cast into continuous strips or slabs, ready for the next stage of the process. This casting is often carried out using a process known as continuous casting, which enables the production of long, semi-finished products called billets, blooms, or slabs.

4. Hot and Cold Rolling

The cast steel is now subjected to rolling in a series of stands. Hot rolling first occurs when the steel, still in a semi-molten state, is passed through rollers at a high temperature. This process gives the steel its initial shape. The steel can then undergo cold rolling, a similar process to hot rolling but carried out at room temperature. Cold rolling gives the steel additional properties such as increased strength and improved surface finish.

5. Finishing

The final key process in the steel production line is finishing, where the rolled steel undergoes further treatment. These treatments can include thermal treatments like annealing and quenching or surface treatments like coating or galvanising. The specific treatment depends on the desired steel product's properties and intended use. After finishing, the steel product is inspected, packed, and readied for shipment to customers.

These key processes in the steel production line, governed by rigorous quality control procedures, ensure that the final steel product meets required standards and specifications.

The Role of Technology in Steel Production

Technological advancements play a vital role in modern steel production, driving improvements in efficiency, quality, and sustainability.

One significant area where technology has brought profound changes is in process automation. Advances in sensors, machine learning, and data analytics have brought forth 'Smart Steel Mills'. These facilities take advantage of automated systems for control, decision-making, and optimization of various production processes. This not only increases efficiency and reduces production time but also ensures consistency in the quality of steel produced.

Besides, the emergence of digital technologies has enabled more seamless integration and communication between different stages of the production line. This greater data sharing aids in faster identification and resolution of issues, enhanced coordination, and resource optimization.

Another significant aspect of technology in steel production is energy efficiency. Technologies aimed at improving energy efficiency and reducing greenhouse gas emissions are increasingly being adopted in the steel industry. For example, the replacement of conventional blast furnaces with electric arc furnaces, which use electricity to melt scrap steel and create new steel, results in significant energy savings and reduced carbon emissions.

There is also ongoing research and development of carbon capture and storage (CCS) technologies. These technologies aim to capture and store CO2 emissions from steel production to mitigate its environmental impact. CCS applications in the steel industry are still mostly in the experimental stage, but they hold great potential for the future.

In summary, technology's role in steel production is not just about enhancing production efficiency and product quality. It also significantly contributes to the steel industry's efforts in minimizing environmental impact and achieving sustainability goals.

Quality Control in Steel Production Line

Understanding the importance of quality control in the steel production line is significant since the quality of the output directly impacts the end uses of steel.

Quality control begins right from the selection of raw materials. All inputs are subjected to strict quality checks to ensure they meet the required specifications. This not only affects the quality of the final product but also the smooth running of the production processes.

Within the production process, each stage has its specific quality checks and parameters. Frequent inspections and checks are performed to ensure compliance with the guidelines. For instance, during the steelmaking process, samples of the molten steel are regularly taken and analyzed to check their chemical composition. Any deviations are corrected by adding necessary elements or compounds to the molten steel.

Similar checks and balances apply to the casting, rolling, and finishing procedures. Quality control in the casting process ensures defects-free ingots, billets, blooms, or slabs. In the rolling process, dimensional accuracy and surface quality are essential parameters checked. Finally, finished products are tested for their mechanical properties, chemical composition, and dimensional accuracy to ensure they meet the specified standards.

Advancements in technology also play a crucial role in quality control. Sensor technology, thermal imaging, ultrasonic testing, and X-ray inspection mechanisms are some of the methods employed to facilitate precise, quick, and non-intrusive quality checks.

Quality control in the steel production line calls for a comprehensive and proactive approach. It ensures that every unit of steel produced meets the desired standards and specifications, guaranteeing safety, reliability, and consistency for its end users.

The Finished Product: From Steel Production Line to the Market

Once the steel has been produced, cast, rolled, and finished, it is ready to leave the production line and make its way to the market. These steel products find their uses across a vast range of sectors and applications, effectively demonstrating steel's versatility and importance in our modern world.

Various forms of steel, like coils, sheets, or plates, are distributed directly to industrial customers, such as automotive, construction, or manufacturing companies. Here, they are further processed to create products like car bodies, building structures, machinery components, and more.

Other steel products are shipped to steel service centers, where they are kept as inventory and further processed according to customer orders. These centers act as an intermediary between steel producers and end-users, providing a wide array of services such as cutting, shearing, slitting, forming, and galvanizing. They cater to customers from diverse sectors and industries, facilitating the efficient distribution of steel.

Sometimes, steel products are also exported to different parts of the world, contributing to global steel trade. These cross-border shipments help cater to demand in regions that lack sufficient domestic steel production.

Once the steel leaves the production line, it therefore embarks on a journey flowing through various sectors of the economy, molding cities, powering industries, and shaping human lives every day. This journey underscores not just the importance of the steel production line, but also the widespread impact of this remarkable material.

The Environmental Impact of Steel Production

The steel production process, while crucial to modern society, does come with considerable environmental implications. It is among industries with the highest energy consumption and CO2 emissions. Therefore, addressing these impacts is pivotal for the industry's sustainability.

One of the primary environmental challenges in steel production is the generation of greenhouse gases. Traditional processes involve burning large amounts of coal, contributing to significant CO2 emissions. Efforts are underway to transition towards more sustainable methods of production, like using electric arc furnaces that melt scrap steel or even exploring hydrogen-based steelmaking techniques.

Apart from CO2 emissions, steel production also produces air pollutants like sulphur dioxide and nitrogen oxides and solid wastes such as slag and dust. Many steel manufacturers implement extensive air and water pollution control systems and waste management strategies to mitigate these effects. For instance, slag is often recycled in cement production or road construction, converting a waste product into valuable resources.

Water usage is another environmental concern in steel production. Large volumes of water are used for cooling and cleaning purposes throughout the process. Steel companies aim to reduce their water footprint through water recycling and by improving the efficiency of their water use.

Moreover, the mining of raw materials also poses environmental challenges such as habitat destruction and soil erosion. Efforts to minimize these impacts include implementing better mining practices and exploring alternative raw material sources.

While significant challenges, these are also opportunities for the steel industry to innovate and evolve. Adopting greener technologies, improving processes, and striving towards a circular economy are not just environmentally responsible—it also offers competitive advantages as businesses and consumers increasingly seek sustainable products.

Future Trends in Steel Production Line

As with all industries, the steel production line is constantly evolving, shaped by technological advancements, market demands, and sustainability initiatives. Below are a few trends that are expected to guide the future of steel production.

1. Digitalization and Industry 4.0

Automation and digitization of the steel production line will continue to be a significant trend. This includes advanced data analytics, machine learning, Artificial Intelligence (AI), and the Internet of Things (IoT). These technologies will drive efficiency, reduce downtime, and optimize resource allocation.

2. Reduction of Carbon Footprint

Green steelmaking will be paramount as the industry faces pressure to reduce carbon emissions. This trend could mean an increase in the use of electric arc furnaces, hydrogen-based steelmaking, and incorporating carbon capture and storage technologies.

3. Resource Efficiency

With increasing consciousness about resource scarcity, efforts to make steel production more resource-efficient will gain importance. This could include recycling and reuse of water and by-products, waste heat recovery, and energy-efficient processes.

4. Customisation and Flexibility

Changes in market demands will require more flexibility in steel production. As customers seek specific grades of steel with tailored properties, the ability to quickly and efficiently switch production to different steel grades will become increasingly vital.

The steel production line of the future will indeed look different from that of today. While the transition may pose challenges, embracing these trends offers the opportunity for the steel industry to remain competitive and sustainable while continuing to provide an essential material for human civilisation.

Conclusion: The Importance of Understanding the Steel Production Line

In conclusion, understanding the steel production line offers profound insights into the intricate journey of transforming raw materials into steel, a material that plays an essential role in various facets of our daily life.

As we have seen, steel production is a complex process that requires precision, experience, and technological prowess. The interplay of raw materials, various processes, quality control measures, and technology come together to produce steel, reflecting the industry’s sophistication and dynamism.

The steel production line isn't static. It continues to evolve, shaped by technological advancements, market demands, and the urgent need for environmentally friendly practices. As consumers, recognizing these trends allows us to make informed choices and contribute towards more sustainable consumption patterns.

Undoubtedly, the steel production line is a testament to human ingenuity and an essential pillar of our modern industrial economy. By understanding the steel production line, we are appreciating the intricate and comprehensive efforts that go into producing one of the most versatile materials known to humankind.

Understanding the Metal Sheet Production Line

What is a metal sheet production line?

A metal sheet production line is a production line setup that transforms raw metal material into finished metal sheets, parts, and structures. This involves various processes such as cutting, bending, and assembling metal.

Who are the main manufacturers of metal sheet production lines?

The main manufacturers include Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd., CIDAN Machinery, Deratech Machine Tool (Suzhou) Corp., Ltd, DMMET GROUP, and others. There are 18 companies in total manufacturing these kinds of production lines.

What kind of products are made in metal sheet production?

Various products such as panel production line items, metal parts, blanks, coils, windows, belts, PVC corrugated sheets, PVC roof tiles, metal frames, and heat sink parts are manufactured using metal sheet production lines.

Are there any special production lines?

Yes, there are special production lines for manufacturing decorative wall panels, ceiling panels, PUR insulation panels, sandwich panels, PUR flexible blocks, insulation panels, and perforated panels.

Which applications require metal sheet production?

Metal sheet production is typically used in a variety of industries including automotive, aerospace, building and construction, consumer goods, industrial machinery, and more. It's an essential process for creating metal parts and structures of various shapes and sizes.