Deformation

Deformation

Was bedeutet Deformation?

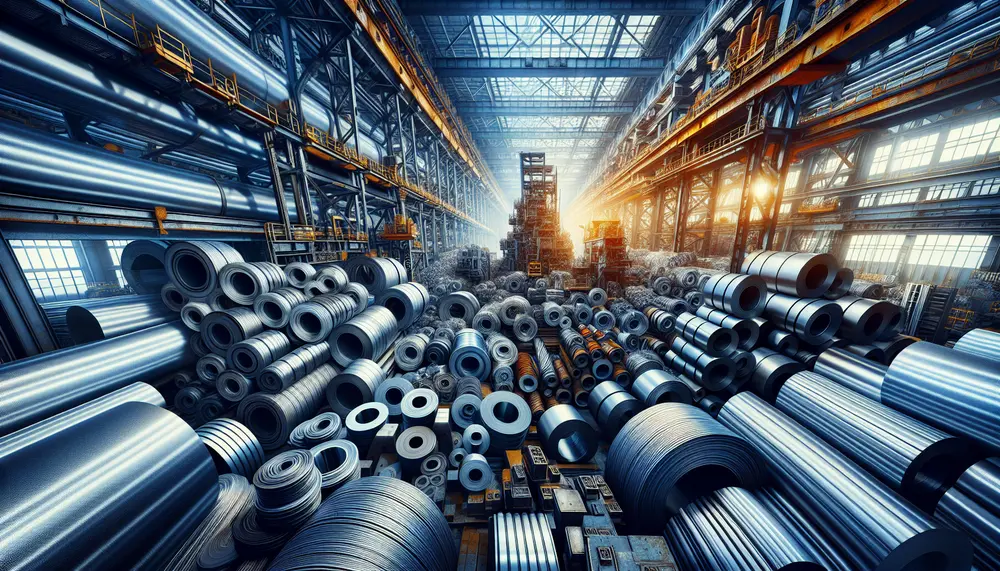

Die Deformation, auch Verformung genannt, ist ein entscheidender Prozess bei der Herstellung von Stahlprodukten. Dieser Begriff beschreibt die Veränderung der Form eines metallischen Werkstücks unter dem Einfluss von Kräften. Während der Deformation passt sich das Metall den verändernden Bedingungen an, ohne dabei seine ursprüngliche Masse oder sein Volumen zu verlieren.

Deformation in der Stahlproduktion

In der Stahlproduktion spielt die Deformation eine essenzielle Rolle. Jedes Metall, einschließlich Stahl, hat eine natürliche Formstabilität. Doch durch Einwirkung von Hitze und Druck kann diese Stabilität kontrolliert verändert werden. Wird ein Stahlprodukt erhitzt, verändert es seine Form durch Deformation leichter. Dadurch kann es in die gewünschte Form gebracht und im Anschluss wieder abgekühlt werden. So bleibt die gewünschte Form erhalten.

Warum ist Deformation wichtig im Stahlhandel?

Für den Stahlhandel ist die Deformation besonders relevant. Die Möglichkeit, Stahl durch Deformation in eine Vielzahl von Formen zu bringen, macht ihn zu einem extrem vielseitigen Material. Ein Stück Stahl kann dadurch seinen Bestimmungsort, seine Funktion und seinen Wert ändern. Die Bedeutung der Deformation ist daher nicht nur technisch, sondern auch wirtschaftlich von großer Bedeutung.

Typen der Deformation

Es gibt mehrere Arten der Deformation, die in der Stahlproduktion eine Rolle spielen. Zu den gängigsten zählen die plastische und die elastische Deformation. Bei der plastischen Deformation behält das Metall seine neue Form dauerhaft bei, auch nachdem die Kräfte, die auf es ausgeübt wurden, entfernt wurden. Im Gegensatz dazu kann ein Metall bei der elastischen Deformation zu seiner ursprünglichen Form zurückkehren, sobald die auf sie ausgeübte Kraft entfernt wird.

Blog Posts with the term: Deformation

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

Steel fabrication involves transforming raw steel into structures or products using various techniques like cutting, bending, and joining to ensure strength and quality. Material selection is critical in this process as it affects the performance and longevity of the final...

The steel making process transforms iron ore into a vital and robust material through complex technical procedures, reflecting human ingenuity and progress. This journey from extraction to the final product involves meticulous steps including smelting in blast furnaces, oxidation for...

Steel is a versatile material essential to modern industry, with various grades tailored for specific uses from construction to technology. Its key advantages include durability, resistance to extreme conditions, and recyclability, making it integral in innovation and sustainability efforts across...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

The steel production casting process involves melting raw materials, refining the molten metal, and pouring it into molds to shape solid products with controlled cooling to prevent defects. The variety of cast steels is determined by carbon content and alloying...

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Quenching is a key process in steel production that rapidly cools metal to change its microstructure, increasing hardness and strength by creating martensitic structure. The choice of cooling medium—water, oil, air or others—affects the rate of cooling and final properties...

Steelmaking slag, a by-product of steel production, can be repurposed for various applications such as construction and cement production due to its valuable properties like strength, durability, and chemical stability. This not only reduces industrial waste but also promotes environmental...