The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The article provides an in-depth look at the metal production process, from mining and refining ores to primary forming and secondary processes like heating, forming, cooling. It also explores different types of metal production methods including forging, casting, drawing/forming/machining, extrusion/cutting,...

Graphite electrodes are essential in steel production, particularly for electric arc furnaces (EAF), where they conduct electricity to melt scrap metal at temperatures up to 3,000°C. Their effectiveness depends on properties like electrical conductivity and thermal shock resistance, influencing the...

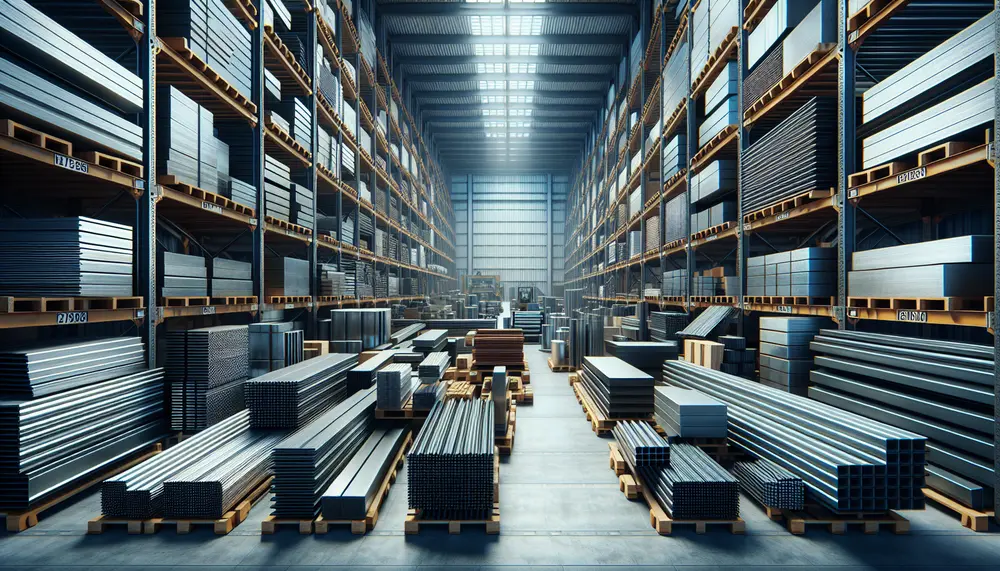

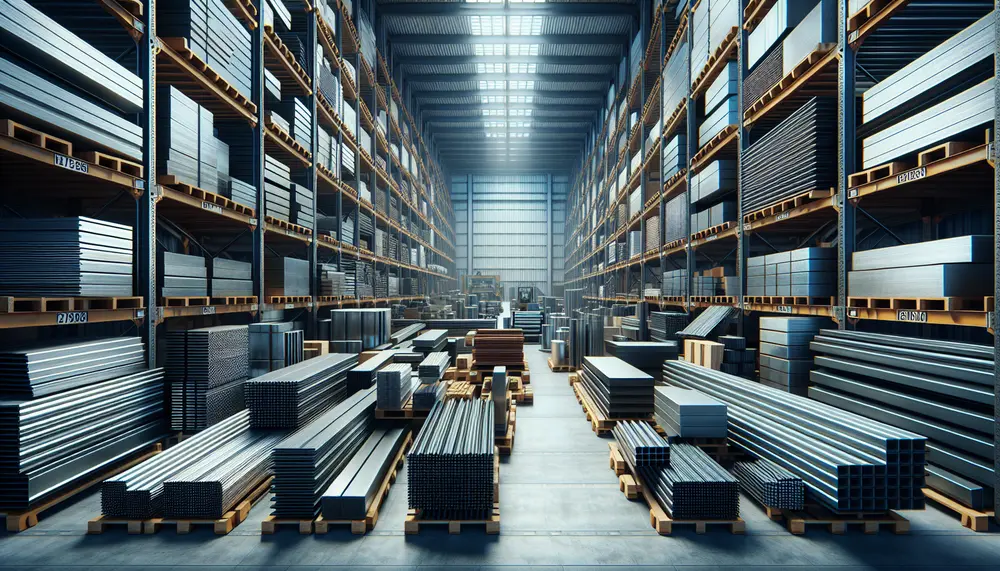

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

Modern steel factories combine advanced technology, automation, and strict quality control to transform raw materials into high-quality steel with precision and efficiency....

Steel production is a complex process that transforms raw materials like iron ore, limestone, and coke into steel through stages such as iron making in blast furnaces, primary and secondary steelmaking for purification and customization, casting to form solid shapes,...

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Steel manufacturing transforms iron ore into steel through a series of processes, starting with smelting in blast furnaces and including primary and secondary steelmaking to adjust chemical composition and remove impurities. The final product is cast, formed, and carefully temperature-controlled...

Metal manufacturing involves techniques like forming, machining, casting, joining, and finishing to create products from raw materials. Understanding these processes is essential in the industry; additional methods include extrusion, stamping, deep drawing, and shearing. Heat treatment alters metal properties through...

Quality steel products are defined by their adherence to industry standards and customer needs, featuring durability and resistance essential for various sectors. High-quality steel is crucial across industries like construction and automotive due to its strength, safety features, and ability...

Steel structural products, due to their strength, durability and versatility, are crucial in modern construction. They offer high strength-to-weight ratio for sturdy yet lightweight structures, resistance against deformation and environmental forces like wind or seismic activity; they're predictable and environmentally...

Steelmaking is a complex process that transforms raw materials like iron ore, coal, and limestone into high-quality steel through stages such as blast furnace melting, refining in Basic Oxygen or Electric Arc Furnaces, alloying, casting, forming, and finishing. Quality control...

The article provides a detailed overview of the steelmaking process, highlighting key components like raw materials, energy sources, and advanced technologies. It explains primary methods (BOF and EAF), step-by-step production stages, and emphasizes sustainability and innovation in modern steel manufacturing....