Grit

Grit

Einführung in den Begriff: Grit

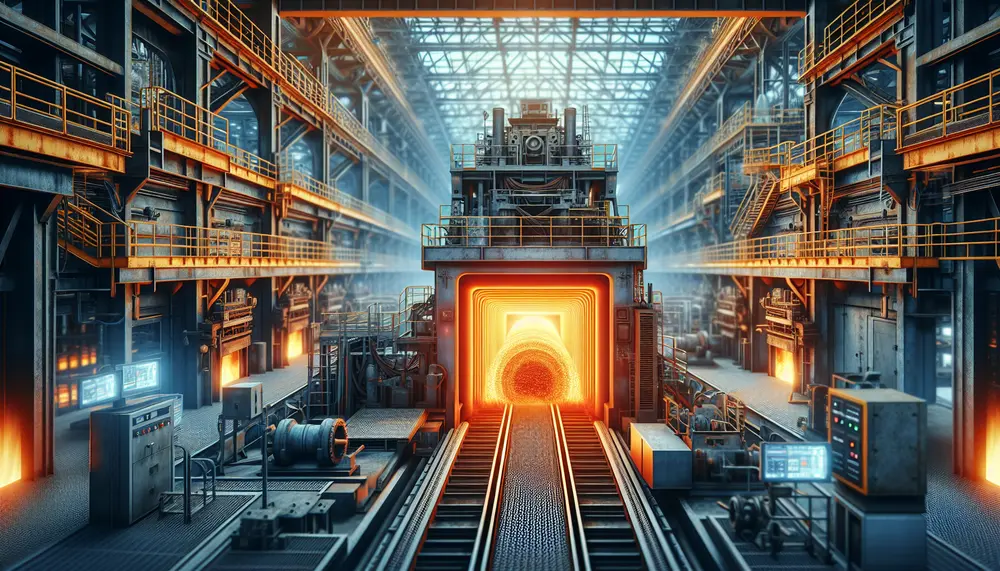

Grit ist ein aus dem Englischen stammender Begriff, der im Bereich der Stahlproduktion und des Stahlhandels eine wichtige Rolle spielt. Er bezieht sich auf kleine, harte Teilchen, oft aus Stahl oder anderen Metallen, die für unterschiedliche Anwendungen verwendet werden. Wichtig zu wissen ist: Grit ist nicht einfach nur Staub oder Abfall. Es ist ein essentieller Bestandteil in verschiedenen Prozessen, die die Qualität und die Effizienz in der Stahlproduktion erhöhen.

Verwendung von Grit in der Stahlproduktion und Stahlhandel

In der Stahlproduktion und im Stahlhandel wird Grit aus verschiedenen Gründen verwendet. Einer der häufigsten Einsatzbereiche ist das Strahlen von Stahl. Diese Methode, auch Sandstrahlen oder Kugelstrahlen genannt, nutzt Grit, um die Oberfläche von Stahlteilen zu reinigen und zu bearbeiten. Das Ergebnis: Eine glatte und saubere Oberfläche, die wichtige Voraussetzung für weitere Verarbeitungsprozesse ist.

Herstellung von Grit

Grit wird oft aus Abfällen von anderen Prozessen in der Stahlproduktion hergestellt. Große Stahlteile, die nicht weiterverwendet werden können, werden zuerst zerkleinert und dann unter Hitze weiter verarbeitet bis sie die gewünschte Größe haben. Durch dieses Recycling-Verfahren gibt die Stahlindustrie einem Abfallstoff einen neuen Nutzen und trägt zur Nachhaltigkeit bei.

Fazit: Die Rolle von Grit in der Stahlindustrie

Zusammenfassend lässt sich sagen: Grit ist ein kleiner, aber wichtiger Bestandteil in der Stahlproduktion und im Stahlhandel. Ohne Grit wäre die Qualitätskontrolle und Oberflächenbearbeitung von Stahl viel schwieriger und weniger effizient. Plus, seine Herstellung trägt zur Nachhaltigkeit der Branche bei. Erinnern Sie sich also an diesen Begriff, wenn Sie das nächste Mal über die Stahlproduktion lesen oder sprechen!

Blog Posts with the term: Grit

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Key Performance Indicators (KPIs) are crucial for the steel industry, guiding operational improvements and aligning business objectives with market demands. They include metrics like energy consumption rates and CO2 emissions, which help companies increase profitability while adhering to sustainability goals....

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

Romania's steel industry, led by LIBERTY Galati, is a key European player with strategic investments in technology and sustainability. The sector faces challenges like environmental impact but contributes significantly to the economy and innovation, aiming for carbon neutrality by 2030....

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

Steel production is intertwined with human rights, necessitating ethical responsibility to protect workers and communities throughout the supply chain. The industry faces challenges such as unsafe working conditions and environmental impacts but is moving towards addressing these through adherence to...

The steel industry in Uganda is vital to its construction sector, supplying materials for infrastructure and buildings with a network of manufacturers, traders, suppliers, and regulators. Steel production meets local demand and exports; understanding the industry involves factors like raw...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...