Ladle

Ladle

Was ist ein Ladle?

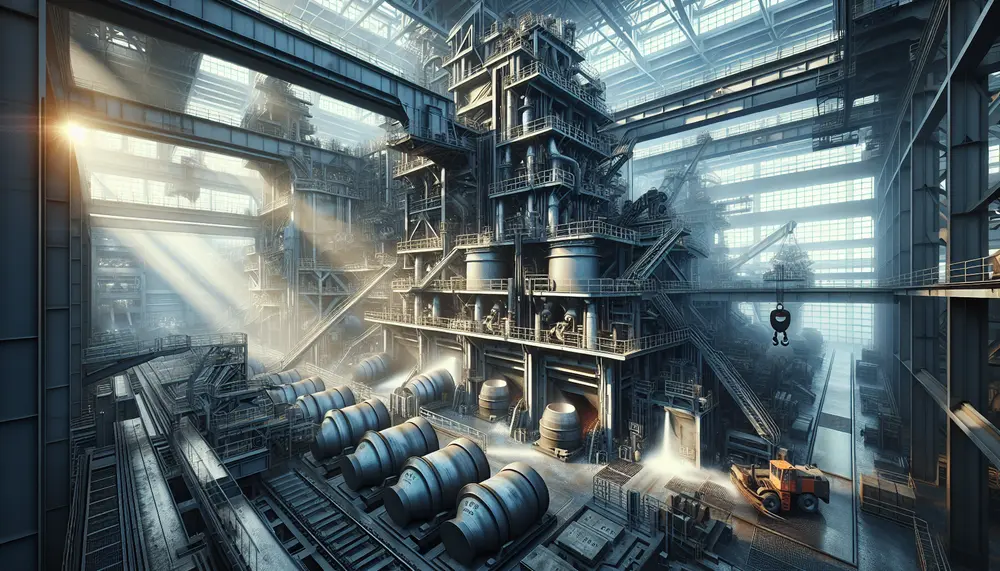

Ladle ist ein grundlegendes aber unerlässliches Werkzeug in der Stahlproduktion und im Stahlhandel. Ein Ladle ist ein großes, oftmals krangetragenes Gefäß, meist aus Stahl, das in der Metallurgie, genauer in der Stahlerzeugung, zum Transport und Gießen von geschmolzenem Metall, im Besonderen Stahl, dient.

Der Name ladle stammt aus dem Englischen und kann mit 'Schöpfkelle' oder 'Gießpfanne' übersetzt werden. Die Größe und Bauart eines Ladle kann je nach Produktionsprozess und Stahlwerk variieren. Einige Ladles können eine Kapazität von bis zu 350 Tonnen geschmolzenem Stahl besitzen.

Funktion und Nutzung eines Ladle

Ein Ladle hat eine sehr wichtige Funktion im Prozess der Stahlproduktion. Er dient dazu, den geschmolzenen Stahl sicher vom Hochofen zur Gießmaschine zu transportieren. Da die Temperaturen in einem Hochofen bis zu 1.600 Grad Celsius erreichen können, ist der Ladle mit hitzebeständigen Materialien gefertigt und innen mit feuerfestem Material ausgekleidet.

Nach dem Schmelzvorgang im Hochofen, wird der flüssige Stahl in den Ladle gefüllt. Er wird dann mittels Kran zur Gießmaschine transportiert, wo er in Formen gegossen wird. Hieraus entstehen die verschiedensten Stahlprodukte, die wir im Alltag verwenden.

Typen von Ladles

Es gibt verschiedene Typen von Ladles und ihre Eigenschaften variieren je nach ihren speziellen Anwendungen in der Stahlproduktion. Einige der häufigsten Ladle-Typen umfassen den 'Tapping Ladle', der zur Entnahme von geschmolzenem Metall aus dem Ofen dient, den 'Treatment Ladle', in dem die Endbehandlung des Stahls stattfindet, und den 'Casting Ladle', der den Stahl zur Gießmaschine transportiert.

Zusammenfassend ist der Ladle ein unentbehrliches Werkzeug in der Stahlindustrie. Ohne seine Funktion, das sichere und effiziente Manövrieren von geschmolzenem Stahl, wäre die Herstellung von Stahlprodukten, wie wir sie heute kennen, nicht möglich.

Blog Posts with the term: Ladle

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The steel making process, which starts with the extraction of iron ore and involves several steps to create different types of steel, is transitioning towards more sustainable methods like the Basic Oxygen Furnace (BOF) method. The BOF method turns raw...

Lime is crucial in steelmaking, acting as a flux to remove impurities like phosphorus and sulfur, enhancing the quality of steel produced through processes such as EAF and BOF while also contributing to environmental sustainability by reducing emissions....

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...