Ladle furnace

Ladle furnace

Ladle furnace ist ein Begriff, der in der Stahlproduktion von zentraler Bedeutigkeit ist. Die Bedeutung und Funktion dessen wollen wir in diesem Glossar Eintrag einmal genauer unter die Lupe nehmen.

Was ist ein Ladle furnace?

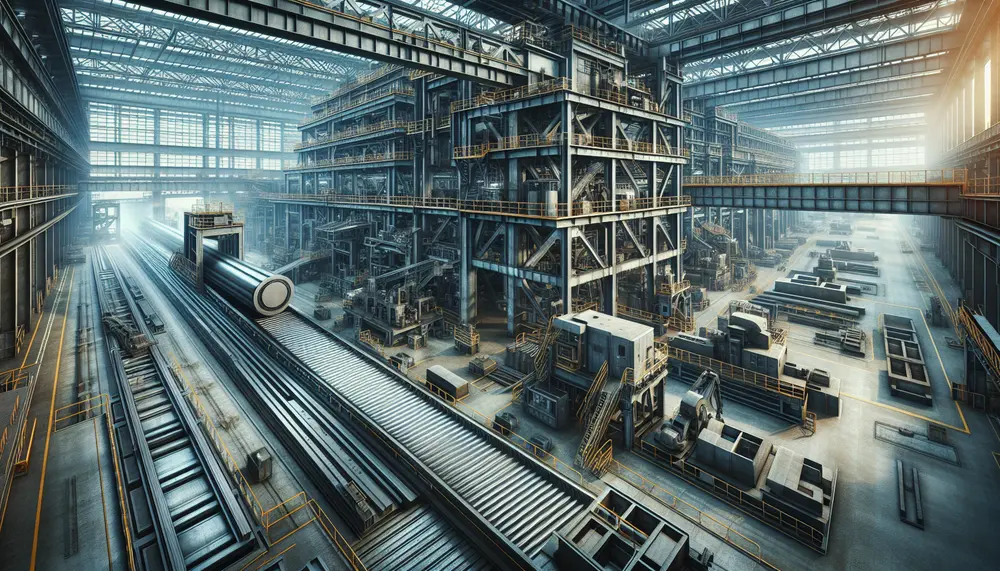

Ein Ladle furnace, auch Pfannenofen genannt, ist ein entscheidender Bestandteil im Prozess zur Stahlerzeugung. Während der Stahlproduktion wird der flüssige Stahl in großen Behältern, den sogenannten Pfannen, transportiert. Diese Pfannen kommen zum Einsatz, um die Temperatur des Stahls zu kontrollieren und seine chemische Zusammensetzung anzupassen.

Der Einsatz vom Ladle furnace

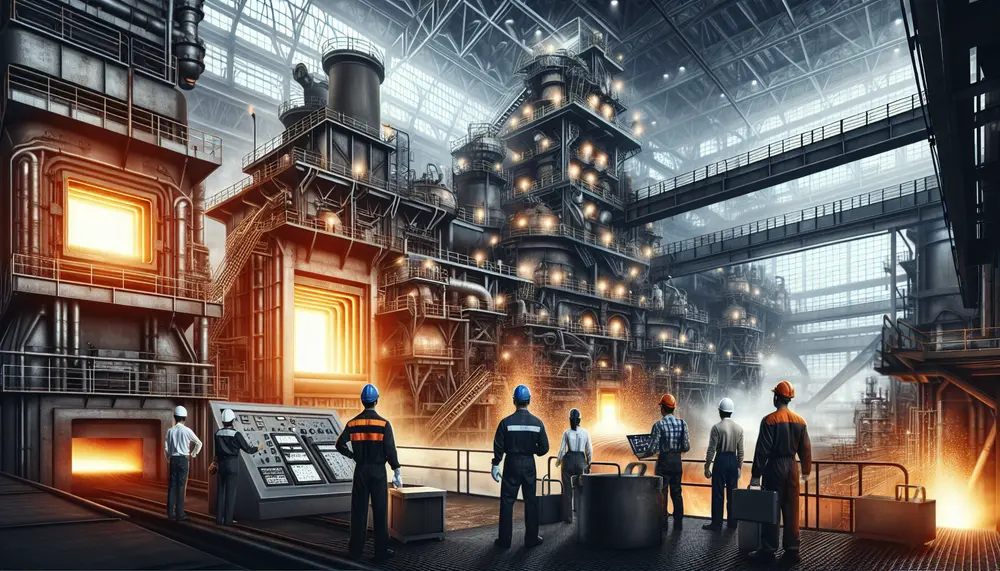

Im Ladle furnace wird der Stahl auf die gewünschte Temperatur erhitzt, die für den nächsten Schritt in der Produktion - wie beispielsweise beim Gießen - benötigt wird. Gleichzeitig wird durch Zugabe von Legierungselementen die chemische Zusammensetzung des Stahls modifiziert. Die genaue Kontrolle und Modifikation der Temperatur und Zusammensetzung ist essenziell, um die spezifischen Eigenschaften des Endproduktes zu erreichen, seien es erhöhte Festigkeit, Korrosionsbeständigkeit oder andere gewünschte Merkmale.

Die Bedeutung vom Ladle furnace

In der Stahlindustrie hat der Ladle furnace eine hohe Relevanz. Ohne diesen ist es nahezu unmöglich, Stahl in gewünschter Qualität herzustellen. Er bietet die Flexibilität, unterschiedliche Eigenschaften des Stahls zu modifizieren und somit verschiedene Stahlsorten herzustellen. Auch ist er ein wichtiges Mittel zur Qualitätskontrolle, da die Qualität des Stahls in hohem Maße von den Bedingungen während des Aufheizens abhängt.

Die Technologie hinter dem Ladle furnace

Der Ladle furnace nutzt elektrische Energie, um die Hitze zum Aufheizen des Stahls zu liefern. Er besteht in der Regel aus drei großen Elektroden, die in die Pfanne eingetaucht werden und den Stahl durch elektrische Entladungen erhitzen. Modernste steuerungstechnische Anlagen ermöglichen eine präzise Kontrolle der Temperatur und der chemischen Zusammensetzung des Stahls.

Nun sollte der Begriff Ladle furnace in seinem Kontext und seiner Bedeutung klar sein. Um noch tiefer in die Welt der Stahlherstellung einzutauchen, nehmen Sie gerne weitere Glossar-Einträge unter die Lupe.

Blog Posts with the term: Ladle furnace

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The steel making LF process, involving a ladle furnace to refine molten steel, is essential for ensuring high-quality and specialized steel grades by controlling temperature and composition. Introduced in the 1960s, advancements in ladle furnaces have optimized this process, enhancing...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

Steel production transforms raw materials like iron ore, coal, and limestone into steel through high-temperature processes in a factory. This complex journey from earth-bound elements to the final product is essential for construction and manufacturing industries, with each material playing...

Steel manufacturing is a complex, multi-stage process that transforms raw materials into the durable metal essential for modern infrastructure. It begins with extracting iron ore and progresses through various phases including blast furnace operation and primary steelmaking methods like Basic...

The steel making process at SAIL involves meticulous selection of raw materials and advanced technology in blast furnaces to produce molten iron, which is then refined using BOF or EAF methods. Rigorous quality control ensures the final product meets international...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

Steelmaking transforms iron into steel by increasing carbon content and refining the material through methods like blast furnaces and adding additives. Modern techniques include Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), focusing on sustainability, with raw materials such...

Steelmaking slag, a by-product of steel production, can be repurposed for various applications such as construction and cement production due to its valuable properties like strength, durability, and chemical stability. This not only reduces industrial waste but also promotes environmental...

Steel products manufacturing transforms raw materials into essential items for modern life, involving a process from conceptualization to final product creation. The steel making process is an intricate journey that includes extraction of iron ore, refining in blast furnaces or...