Production schedule

Production schedule

Was ist ein Production schedule?

Ein Production schedule ist das Rückgrat jeder erfolgreichen Stahlproduktion und des Stahlhandels. Es handelt sich dabei um eine detaillierte Roadmap, die zeigt, welche Arbeitsschritte zur Herstellung von Stahlprodukten nötig sind und wann diese ausgeführt werden müssen. Dieser Fahrplan ist entscheidend, um sicherzustellen, dass die Produktion effizient und termingerecht abläuft.

Warum ist ein Production schedule wichtig?

Ein gut geplanter Production schedule kann die Effizienz und Produktivität einer Stahlproduktion stark verbessern. Es hilft dabei, den Materialfluss zu steuern, Arbeitskraft effektiv einzusetzen und teure Produktionsausfälle zu vermeiden. Somit ist es von zentraler Bedeutung für eine profitable Produktion und einen reibungslosen Handel mit Stahl.

Bestandteile eines Production schedule

Ein typischer Production schedule in der Stahlindustrie umfasst Angaben zur Reihenfolge der Produktionsprozesse, zur benötigten Zeit für jeden Prozess und zum erwarteten Ausstoß. Es berücksichtigt auch Faktoren wie die Verfügbarkeit von Rohstoffen und Maschinen, Personaleinsatz und potenzielle Risiken oder Verzögerungen.

Erstellen eines Production schedule

Das Erstellen eines Production schedule erfordert ein gutes Verständnis des Herstellungsprozesses von Stahl und seiner Logistik. Es umfasst die Analyse der Produktionskapazität, die Bewertung der Lagerbestände und das Festlegen der Produktionsziele. Dank moderner Software können Production schedules dynamisch angepasst und optimiert werden, um auf unerwartete Herausforderungen zu reagieren.

Zusammenfassung

Zusammenfassend lässt sich sagen, dass ein guter Production schedule unerlässlich für eine effiziente und profitable Stahlproduktion und einen reibungslosen Stahlhandel ist. Er hilft, Ressourcen sinnvoll einzusetzen, die Produktion zu koordinieren und potenzielle Störungen im Voraus zu erkennen und zu vermeiden.

Blog Posts with the term: Production schedule

Key Performance Indicators (KPIs) are crucial for the steel industry, guiding operational improvements and aligning business objectives with market demands. They include metrics like energy consumption rates and CO2 emissions, which help companies increase profitability while adhering to sustainability goals....

Steel production is a highly energy-intensive process with significant environmental impacts, making the understanding and monitoring of energy consumption at each stage crucial for sustainability. Energy efficiency in steel manufacturing is essential for cost-effectiveness, competitiveness, and reducing carbon emissions, with...

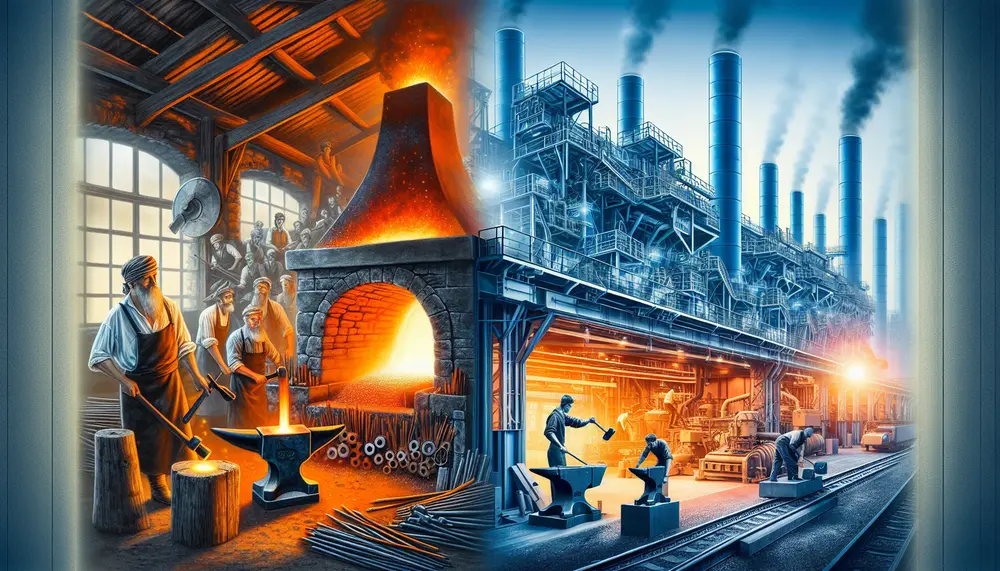

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

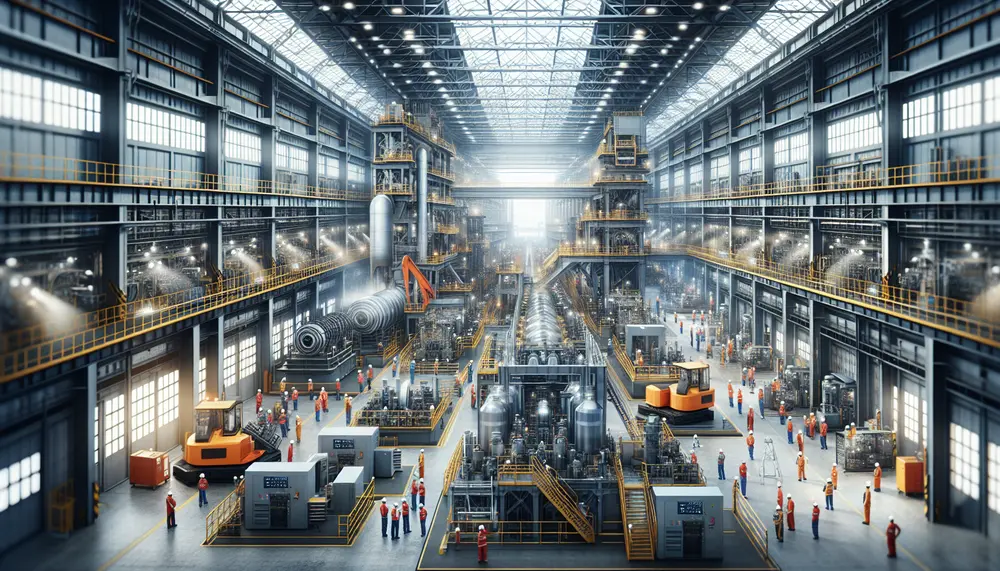

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Steel making is a complex process that refines raw materials into steel, involving steps like removing impurities and adding alloying elements. Modern methods include Basic Oxygen Steelmaking (BOF) and Electric Arc Furnace (EAF), with advancements in continuous casting and technology...

The steel making process begins with mining and refining iron ore, followed by smelting in a blast furnace to produce pig iron which is then refined into steel using methods like basic oxygen furnaces or electric arc furnaces. Advances in...

Steel production is a major contributor to global emissions, with traditional methods being energy-intensive and emitting various pollutants. Efforts to reduce its environmental impact include adopting cleaner technologies like electric arc furnaces (EAF) and strategies such as carbon capture and...

Steel production has evolved from the labor-intensive Open Hearth Process to the efficient Basic Oxygen Steelmaking and Electric Arc Furnaces, reflecting a century of technological advancements that have increased sustainability and reduced environmental impact. These innovations have transformed steelmaking into...

Steel production in Malaysia, utilizing the Electric Arc Furnace method and benefiting from its ASEAN location, has grown significantly due to domestic demand and government initiatives like NIMP 2030. The industry faces challenges such as environmental impact but remains a...

The article discusses the diverse and rewarding career opportunities in the steel industry, highlighting roles from manufacturing to management and emphasizing the importance of skills like problem-solving and adaptability. It underscores continuous learning for advancement in this evolving sector that...

Forecasting steel production is crucial for planning in industries and governments, involving analysis of economic indicators, market trends, and geopolitical factors to predict future output. Accurate forecasts are vital as they inform decision-making processes across various sectors by anticipating supply-demand...

The steel products industry is vital to global manufacturing, providing materials for infrastructure and various sectors with a focus on innovation and sustainability. It produces diverse types of steel categorized by shape—flat, long, tubular—and operates in a complex international market...

Choosing the right steel making equipment manufacturer is crucial for ensuring efficiency, reliability, and safety in production processes. Key considerations include assessing experience and reputation, evaluating product range and quality, prioritizing technology and innovation, understanding customization capabilities, emphasizing customer support...