Profit margin

Profit margin

Was ist die Gewinnspanne?

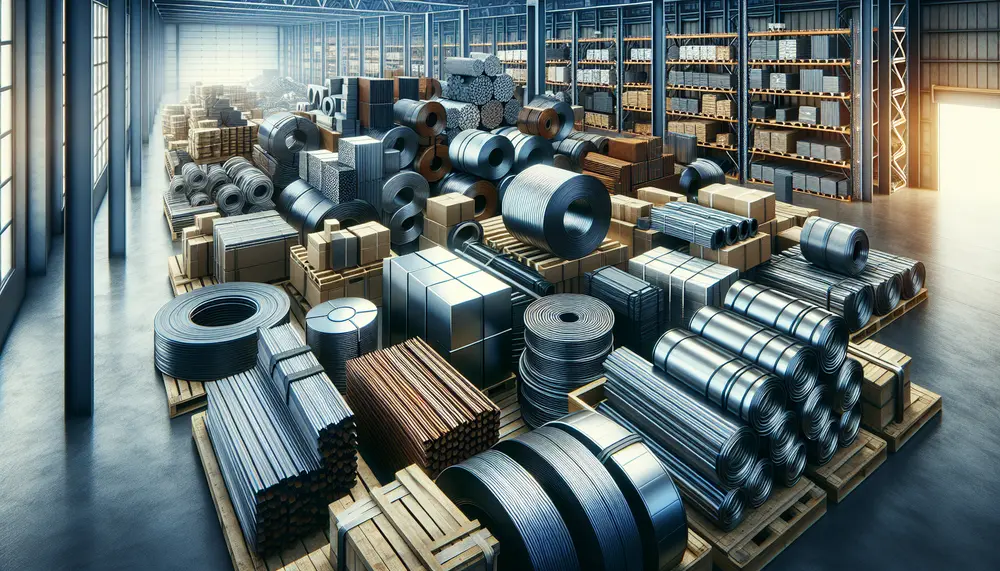

Die Gewinnspanne, auch bekannt als "Profit margin", ist ein wichtiger Finanzindikator, der in der Stahlproduktion und im Stahlhandel verwendet wird. Sie hilft Unternehmen zu bewerten, wie rentabel ihre Geschäftspraktiken sind. In einfachen Worten, sie misst den Anteil des Gewinns, der bei jedem Verkauf erzielt wird.

Warum ist die Gewinnspanne wichtig in der Stahlproduktion und im Stahlhandel?

In der Stahlproduktion und im Stahlhandel ist das Verständnis der Gewinnspanne von entscheidender Bedeutung. Der Stahlmarkt kann sehr volatil sein mit sich ständig ändernden Kosten für Rohmaterialien, Energie und Arbeit. Die Gewinnspanne hilft den Unternehmen, die Rentabilität ihrer Produktion und Verkäufe zu überwachen. Eine hohe Gewinnspanne könnte auf effiziente Geschäftspraktiken oder hohe Verkaufspreise hinweisen, während eine niedrige Gewinnspanne auf Probleme mit den Kosten hinweist.

Wie wird die Gewinnspanne berechnet?

Die Berechnung der Gewinnspanne ist recht einfach. Teilen Sie einfach den Nettogewinn eines Unternehmens durch den Gesamtumsatz und multiplizieren Sie das Ergebnis mit 100. Das gibt Ihnen die Gewinnspanne in Prozent. Es ist wichtig zu bemerken, dass der Nettogewinn die Kosten des Unternehmens für die Produktion von Waren oder Dienstleistungen abzieht.

Gewinnspanne in der Praxis

Ein Beispiel in der Stahlindustrie könnte sein: Ein Stahlunternehmen verkaufte Produkte für insgesamt 1 Million Euro und hatte Kosten von 700.000 Euro. In diesem Fall wäre der Nettogewinn 300.000 Euro. Wenn wir 300.000 durch 1.000.000 teilen und mit 100 multiplizieren, erhalten wir eine Gewinnspanne von 30%. Dies bedeutet, dass für jeden verkauften Euro Produkt, das Unternehmen 30 Cent als Gewinn behält.

Blog Posts with the term: Profit margin

The African steel industry is growing and diverse, with varying levels of resource availability and technological sophistication across countries. It plays a crucial economic role by stimulating growth in other sectors, creating jobs, contributing to GDP, reducing import dependency, and...

Kuwait's steel production is on the rise due to government initiatives, modernized facilities, and strategic location for trade. This growth supports economic diversification and attracts investment but also raises concerns about environmental impact and resource usage....

Steel production is a highly energy-intensive process with significant environmental impacts, making the understanding and monitoring of energy consumption at each stage crucial for sustainability. Energy efficiency in steel manufacturing is essential for cost-effectiveness, competitiveness, and reducing carbon emissions, with...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...

HTS codes are essential for classifying steel products in international trade, determining tariffs and compliance with regulations. They require precise understanding due to their complexity and frequent updates influenced by global trade changes....

Turkey's steel industry is a key economic pillar, known for its high-quality production and strategic location that bridges Europe and Asia. Despite challenges like raw material dependency and global price fluctuations, the sector has shown resilience through innovation and contributes...

Steel production is intertwined with human rights, necessitating ethical responsibility to protect workers and communities throughout the supply chain. The industry faces challenges such as unsafe working conditions and environmental impacts but is moving towards addressing these through adherence to...

The steel industry in Thailand is a significant and growing sector, fueled by the country's economic growth, urbanization, and strategic location in Southeast Asia. Despite its robust domestic market and government support for industrial expansion, challenges such as high energy...

The VAD steelmaking process, or Vacuum Arc Degassing, is crucial for producing high-quality steel by removing impurities and gases like hydrogen and nitrogen through a vacuum environment, resulting in purer and more homogeneous steel with enhanced mechanical properties....

The UK steelmaking industry has a rich history dating back to the Industrial Revolution and remains vital for infrastructure and economy, facing modern challenges like global competition and environmental concerns. Key players include Tata Steel and British Steel Limited, with...

The steel industry is adapting to current market trends, including geopolitical tensions and technological disruptions, while moving towards sustainable practices. Global events like the Ukraine conflict and COVID-19 pandemic have impacted supply chains and trade flows, with innovations in manufacturing...

Recycling is crucial in the steel industry due to its environmental benefits and sustainability. Steel can be infinitely recycled without losing essential properties, reducing new material needs and energy-intensive processes; it also minimizes air pollution by 86%, water use by...

The steel making business offers lucrative opportunities driven by rising demand in sectors like construction and automotive, requiring understanding of market dynamics, strategic planning, and significant investments in technology and infrastructure to succeed....

The US steel industry has evolved from traditional methods to sustainable practices, focusing on recycling and technological innovation, with key players like Cleveland-Cliffs and Nucor leading advancements. Despite challenges such as international competition and environmental regulations, the industry remains a...

Steel production statistics are essential for assessing the global economy and steel industry health, reflecting industrial activity and economic trends through raw output and capacity utilization rates. These figures are influenced by technological advancements, market demands, trade policies, environmental considerations,...