Refractory materials

Refractory materials

Was sind feuerfeste Materialien (Refractory materials)?

Wenn wir vom Stahlproduktion und Stahlhandel sprechen, ist es unmöglich, am Konzept von feuerfesten Materialien oder Refractory materials vorbeizukommen. Aber was macht diese Komponenten so wichtig?

Die Rolle von Refractory materials in der Stahlproduktion

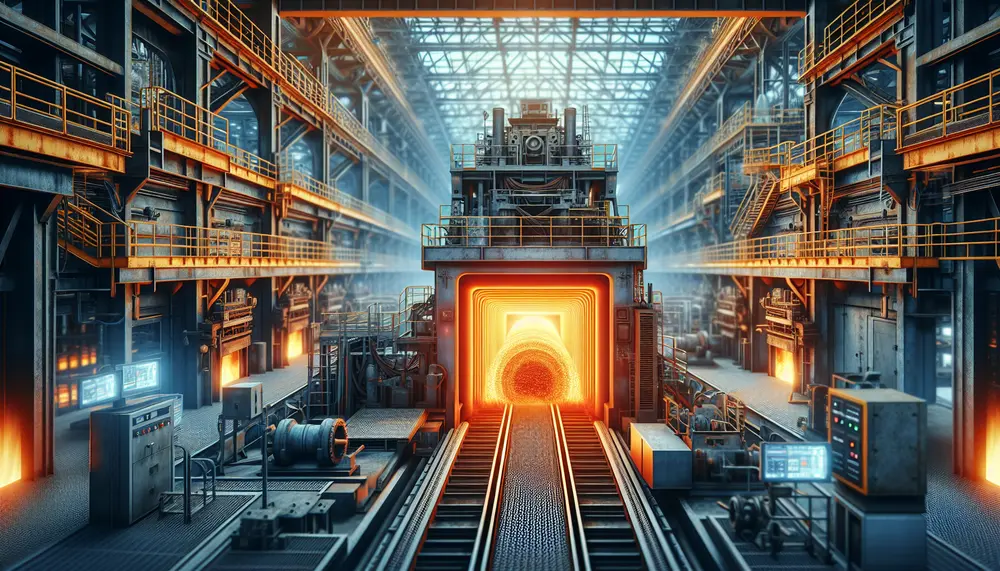

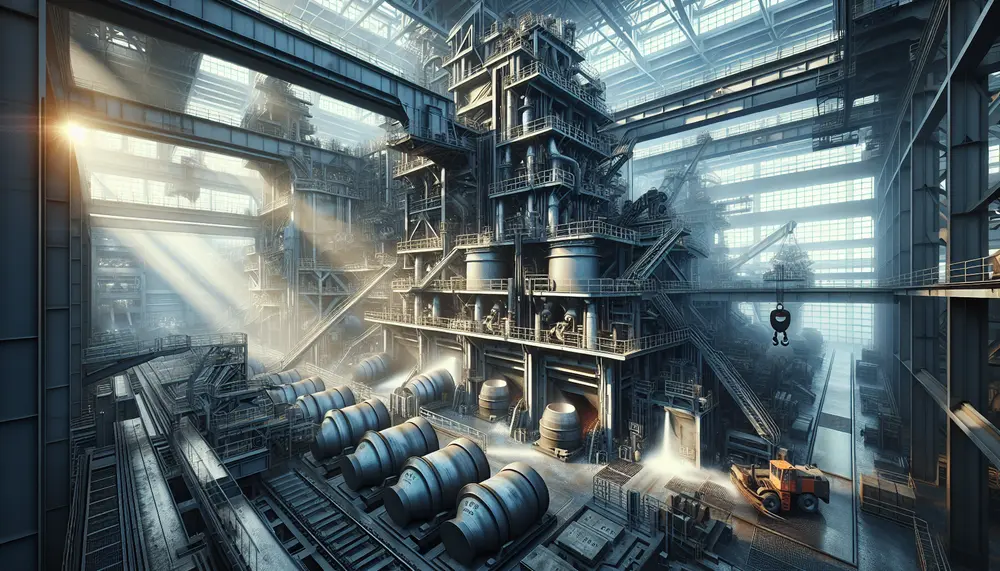

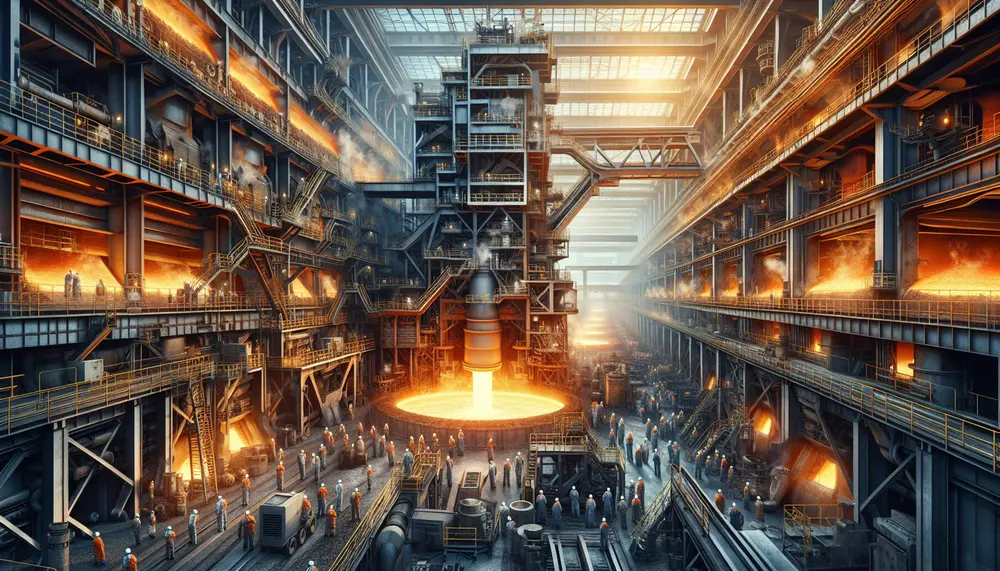

Feuerfeste Materialien sind spezielle Substanzen, die dazu verwendet werden, Strukturen oder Produkte zu schützen, die bei hohen Temperaturen eingesetzt werden. Diese Materialien sind unerlässlich in der Stahlproduktion, weil sie dazu beitragen, dass die notwendigen extrem hohen Temperaturen sicher erreicht und gehalten werden können.

Eigenschaften von Refractory materials

Eine Kerneigenschaft von Refractory materials ist, dass sie hohe Temperaturen widerstehen können, ohne ihre Form zu verlieren oder abzubauen. Dies macht sie ideal für den Einsatz in Hochtemperatur-Umgebungen, wie zum Beispiel in Stahlöfen.

Zusätzlich zu ihrer Hitzeverträglichkeit sind feuerfeste Materialien oft auch gegen chemische Angriffe resistent. Dies ist wichtig, da in der Industrie oft korrosive Materialien eingesetzt werden, die normale Materialien leicht zerstören können.

Anwendungen von Refractory materials im Stahlhandel

Im Stahlhandel sind feuerfeste Materialien an vielen Stellen wichtig. Sie werden zum Beispiel bei der Herstellung von Stahlbehältern, im Schweißen, bei der Herstellung von Stahlprodukten und bei vielen anderen Anwendungen eingesetzt. Ohne feuerfeste Materialien wäre die sichere und effektive Produktion von Stahl viel schwieriger.

Zusammenfassung

Feuerfeste Materialien, oder Refractory materials, sind ein integraler Bestandteil der Stahlproduktion und des Stahlhandels. Sie schützen Strukturen und Produkte vor extremen Temperaturen und chemischen Angriffen, und machen so die Produktion und Verarbeitung von Stahl sicher und effektiv.

Blog Posts with the term: Refractory materials

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

The blast furnace steel making process involves transforming raw materials into molten iron, which is then processed to produce steel. Key components include coke, iron ore and limestone; the former provides heat while the latter two undergo chemical reactions in...

The article discusses various steelmaking furnace types, highlighting their unique characteristics and applications in the industry, emphasizing factors like efficiency, environmental impact, and suitability for different production needs....

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

The Basic Oxygen Furnace (BOF) process, developed in the mid-20th century by Robert Durrer, revolutionized steel production by using pure oxygen to convert molten iron into high-quality steel efficiently. This method involves charging a furnace with molten iron and scrap...

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

The Industrial Revolution brought significant advancements in steel production, including the Bessemer process which revolutionized manufacturing by enabling mass production of high-quality steel. These innovations facilitated infrastructure expansion and technological progress, laying the foundation for modern society....

Steel making refractory materials are essential for lining furnaces and equipment in steel production, with various types like fireclay, high alumina, silica, magnesite, and chromite refractories tailored to specific conditions. These materials ensure heat containment, protect equipment from damage, maintain...

Henry Bessemer revolutionized steel production by inventing a process that made mass production of high-quality steel possible, significantly reducing costs and impacting various industries. His invention was spurred by his early inventive spirit and lack of formal education, leading to...

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...