Vessel

Vessel

Was ist ein 'Vessel' in Steel Production and Steel Trade?

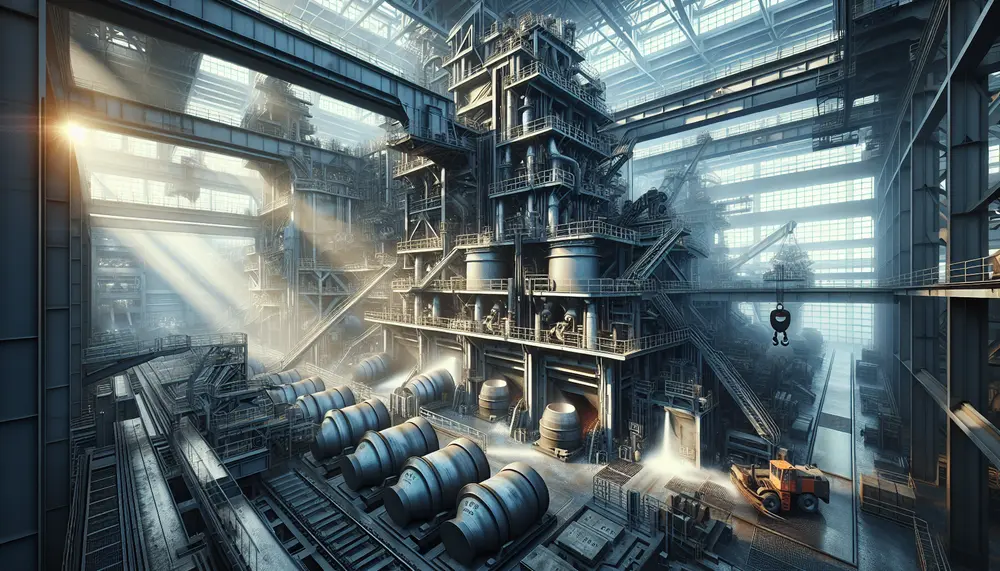

Ein Vessel oder auf Deutsch auch 'Gefäß' genannt, ist ein Begriff, der in der Stahlproduktion und im Stahlhandel häufig genutzt wird. Es bezieht sich auf einen großen Behälter oder Tank, der in verschiedenen Schritten des Stahlherstellungsprozesses zum Einsatz kommt.

Verwendung von 'Vessel' in der Stahlproduktion

Beim Prozess der Stahlherstellung wird das Vessel genutzt, um Rohstoffe wie Eisenerz, Kohle und Kalkstein zu schmelzen und zu mischen. Das Vessel ist so konstruiert, dass es den extrem hohen Temperaturen standhält, die für diese Phase des Prozesses benötigt werden.

'Vessel' im Stahlhandel

Auch im Stahlhandel spielt das Vessel eine Rolle. Hier bezieht es sich auf das Transportmittel, also das Schiff, das den Stahl von der Produktionsstätte zum Kunden bringt. Die Größe des Vessels kann variieren, abhängig von der Menge des zu transportierenden Stahls.

Warum ist das 'Vessel' wichtig?

Ohne das Vessel wäre die Stahlproduktion und der Stahlhandel, wie wir sie heute kennen, nicht möglich. Es ist das Herzstück der Produktionsprozesse und sorgt dafür, dass der Stahl sicher und effizient von A nach B gelangt.

Blog Posts with the term: Vessel

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

Steel was crucial in World War II, serving as the backbone for military equipment and influencing nations' industrial might. The escalation of steel production played a pivotal role in the Allied victory, with advancements in technology and massive job creation. Steel's...

South Korea is a key player in the global steel market, known for its production capacity, innovation, and high-quality specialty steels. The industry's economic impact on Korea includes job creation and skill development while driving foreign investment and technological advancement;...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Lime is crucial in steelmaking, acting as a flux to remove impurities like phosphorus and sulfur, enhancing the quality of steel produced through processes such as EAF and BOF while also contributing to environmental sustainability by reducing emissions....

The article traces the evolution of steel making from its inception in the Iron Age to modern times. It highlights key milestones such as the Bronze Age's dawn of iron use, 17th century advancements in furnace technology and iron production,...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...