Posts on the Topic Carbon

Steelmaking nouns are essential for clear communication and safety in the steel industry, with evolving terminology requiring an up-to-date glossary. This article explains key terms like alloy, arc furnace, austenite, blast furnace, billet, basic oxygen process, carbon content, converter, casting,...

The art of medieval steelmaking combined intuition, tradition, and a deep understanding of metallurgy to create strong yet flexible materials essential for tools, weapons, and status symbols. Despite limited scientific knowledge and resources, artisans mastered techniques like carbon infusion and...

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

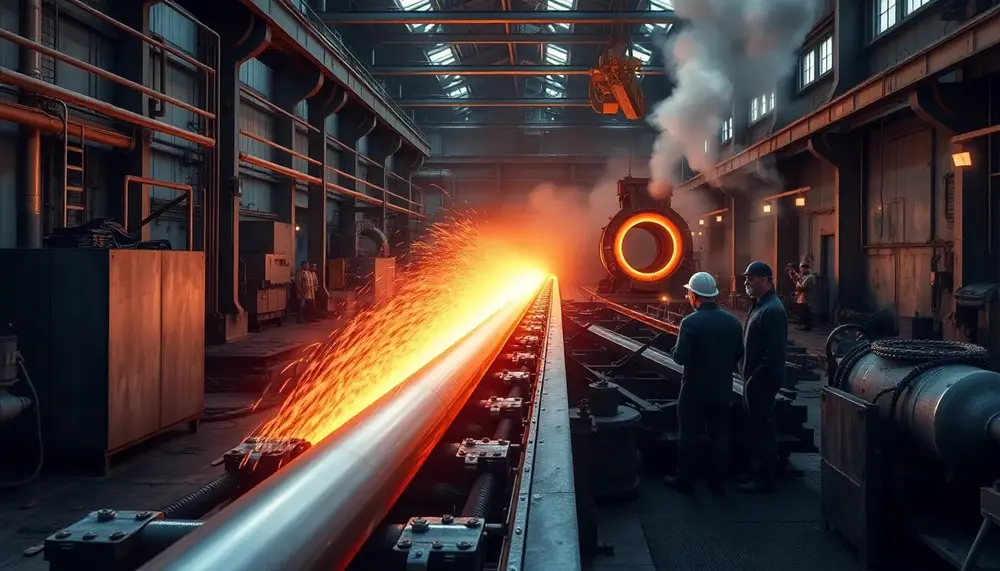

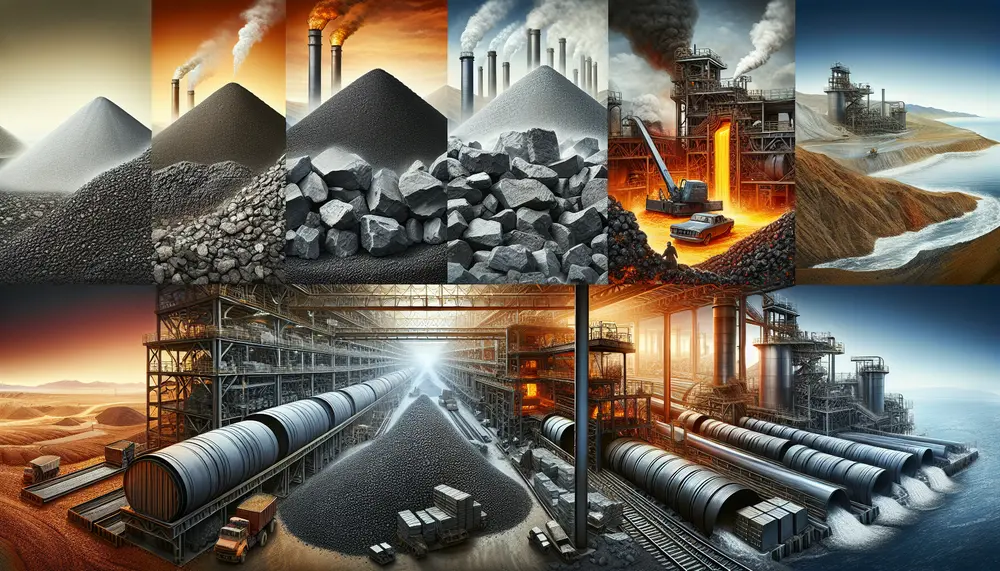

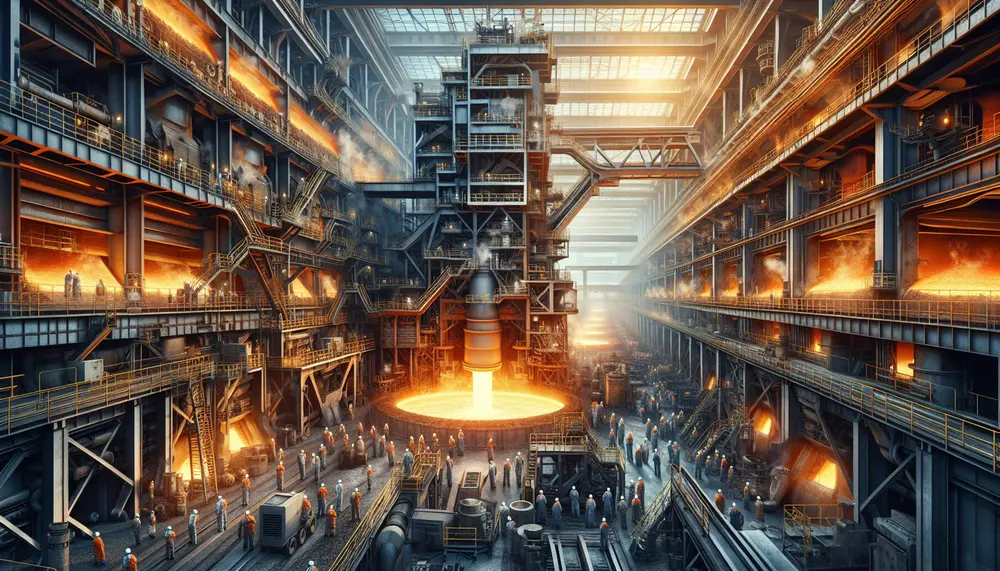

Steelmaking combines science and engineering to transform raw materials into tailored steel products through precise control of temperature, composition, and reactions. Its evolution reflects human innovation, from ancient smelting techniques to modern sustainable methods driven by advanced theoretical principles like...

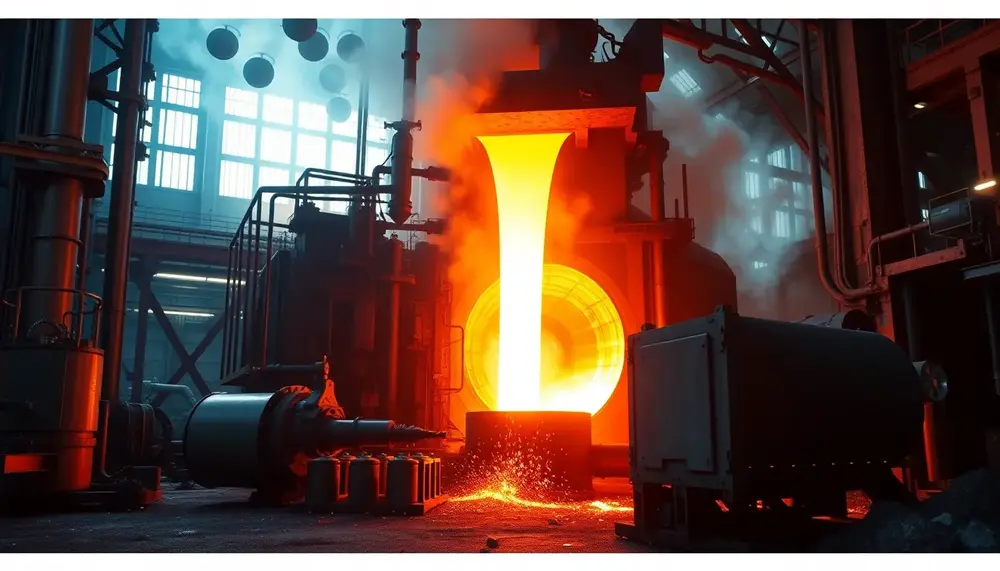

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...