Posts on the Topic Efficiency

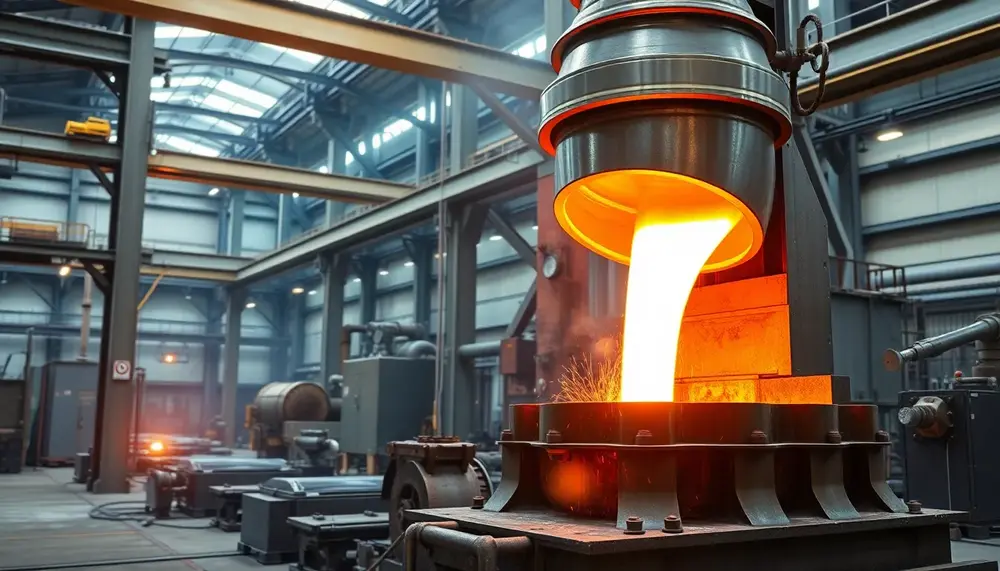

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

The transformation of steel production, marked by innovations like the Bessemer Process and later advancements, revolutionized industries by enabling faster, cheaper, and higher-quality steel manufacturing. These breakthroughs fueled industrial growth, urbanization, modern infrastructure development, and laid the foundation for a...

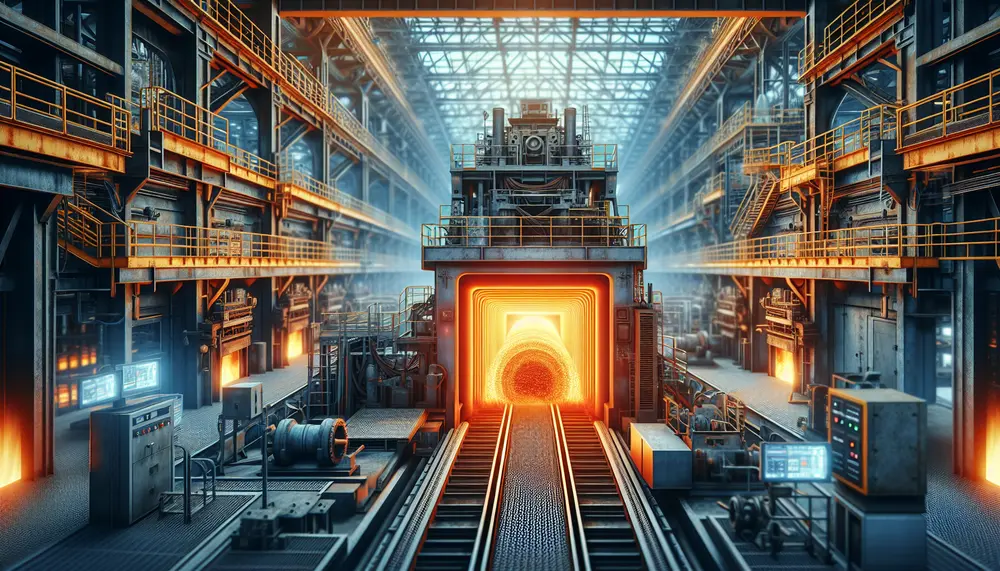

Danieli is revolutionizing steel production by integrating advanced, sustainable technologies like the Steel Plant Model and green solutions to enhance efficiency and reduce environmental impact. Their innovative approach combines adaptability, energy optimization, and emission reduction while setting new industry benchmarks...

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

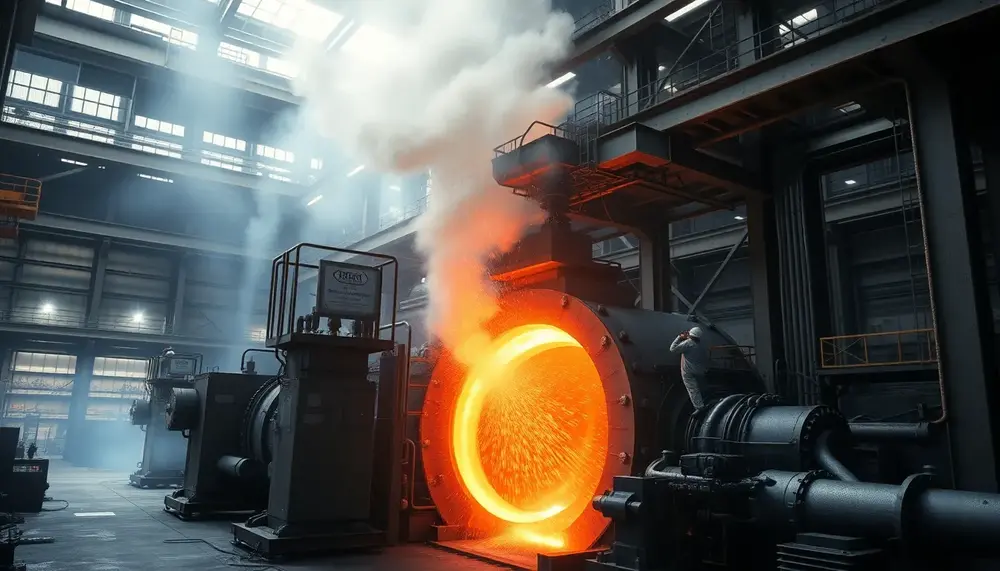

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

CFD steelmaking jobs are on the rise, offering a blend of technology and metallurgy to optimize processes in the steel industry through simulations that enhance efficiency and sustainability. Professionals in this field require technical proficiency, software expertise, analytical skills, problem-solving...

The reduction ratio in steel making is crucial for optimizing efficiency, cost-effectiveness, and quality by determining the mechanical properties of steel through factors like temperature and impurities. Modern advancements have shifted from traditional ratios to more efficient ones, reflecting innovation...

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....