Posts on the Topic Iron

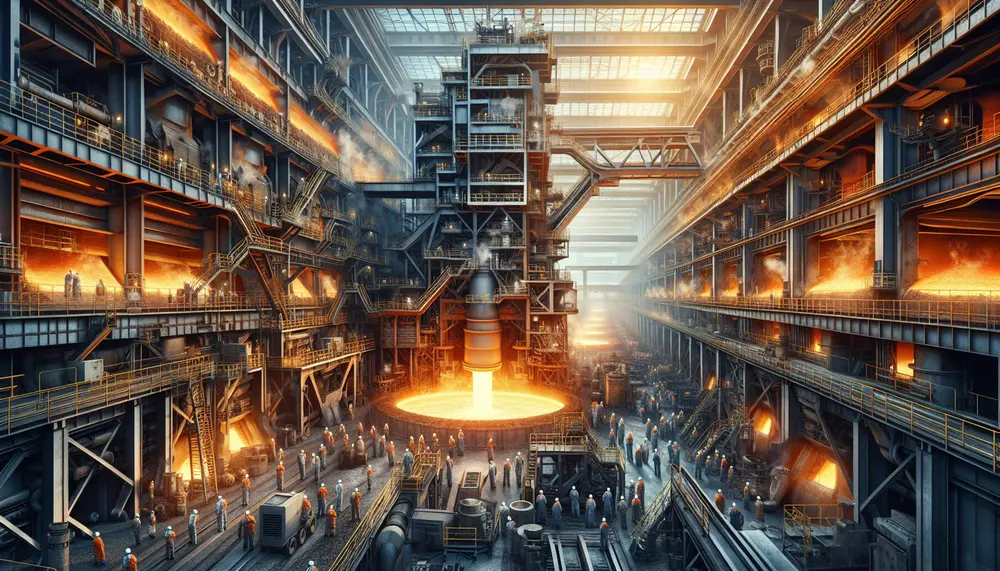

Steel manufacturing transforms raw materials like iron ore into robust steel products through a complex process involving chemistry, physics, and engineering. This journey from ancient methods to modern techniques includes steps such as blast furnace operations and refining processes, highlighting...

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

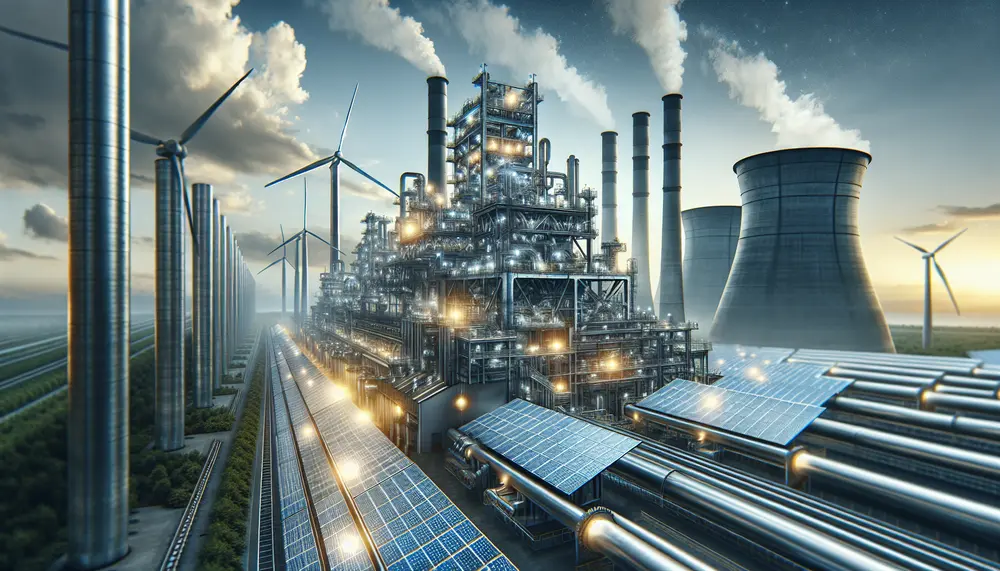

Hydrogen steelmaking offers a sustainable alternative to traditional methods by using hydrogen as a reducing agent, significantly cutting carbon emissions and enhancing product quality. This method not only reduces the environmental impact but also supports integration with renewable energy sources,...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

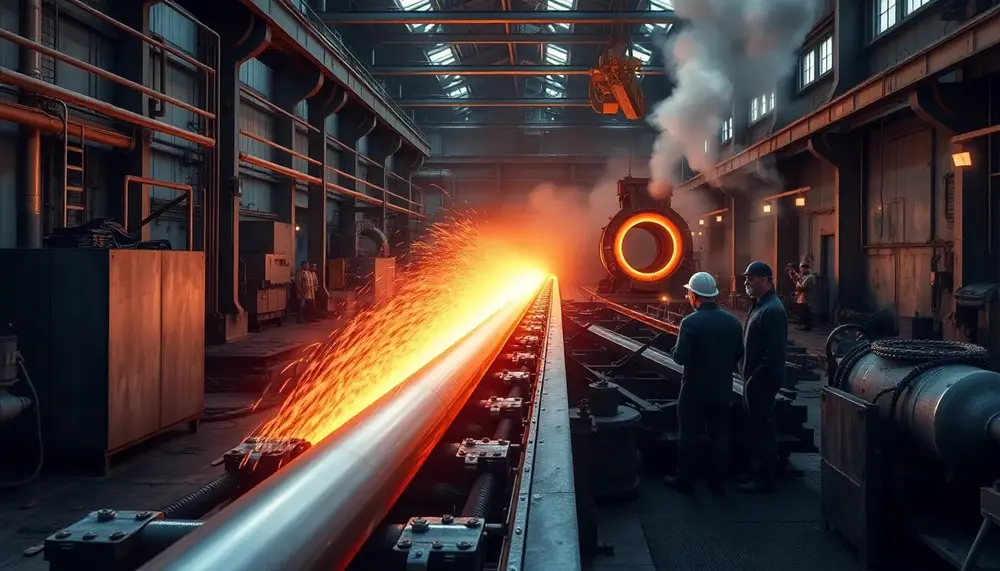

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

Hydrogen is revolutionizing steel production by serving as a cleaner reducing agent, enabling the industry to reduce carbon emissions and align with sustainability goals. However, integrating hydrogen technology faces challenges such as infrastructure overhaul, storage and transportation logistics, economic factors,...