Posts on the Topic Quality

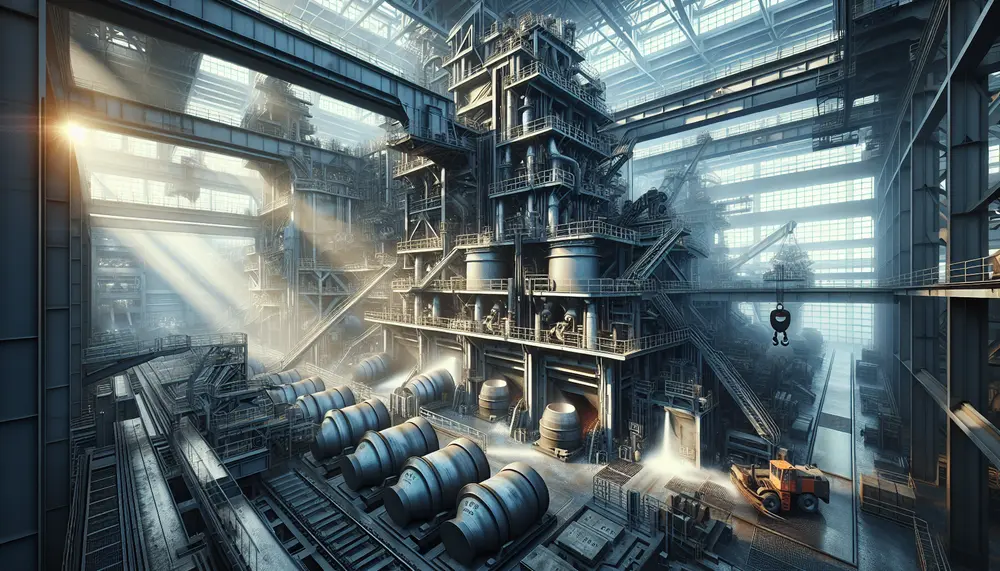

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

The reduction ratio in steel making is crucial for optimizing efficiency, cost-effectiveness, and quality by determining the mechanical properties of steel through factors like temperature and impurities. Modern advancements have shifted from traditional ratios to more efficient ones, reflecting innovation...

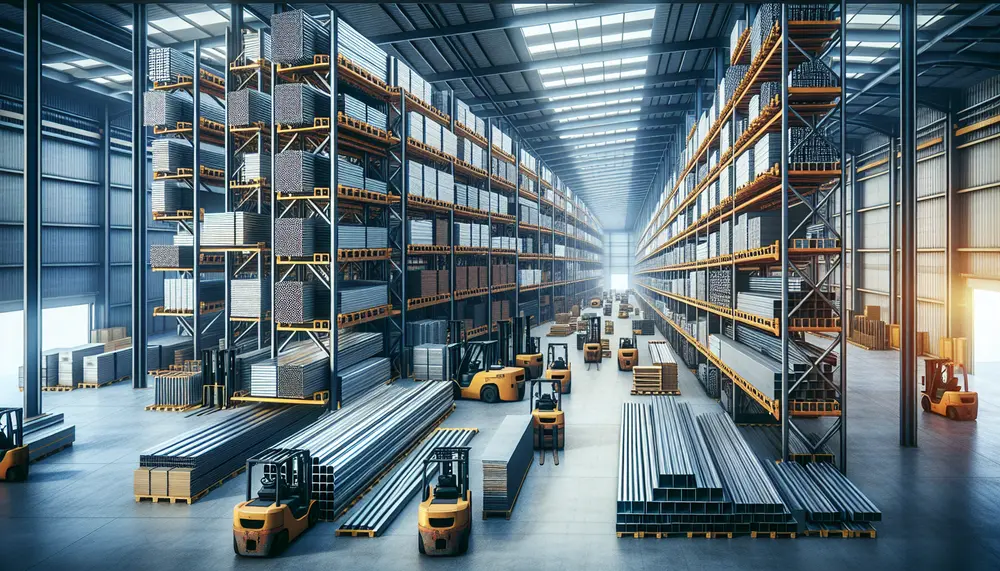

Choosing the right steel making equipment manufacturer is crucial for ensuring efficiency, reliability, and safety in production processes. Key considerations include assessing experience and reputation, evaluating product range and quality, prioritizing technology and innovation, understanding customization capabilities, emphasizing customer support...

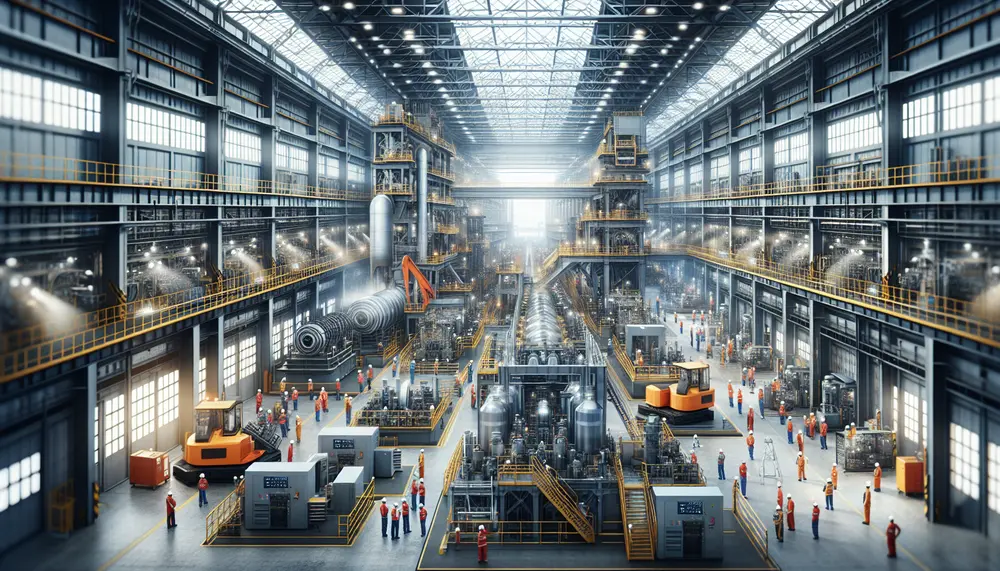

Becoming a steel making operator involves overseeing the production of steel, ensuring quality and safety standards, and requires technical skills, attention to detail, problem-solving abilities, physical stamina, communication skills, and safety awareness. Educational requirements typically include a high school diploma...

Partnering with the largest steelmaking company offers numerous advantages, including a reliable supply chain, quality assurance, cost efficiency, access to innovation and technology, sustainable practices, global reach, and exceptional customer support. These benefits can significantly enhance your business operations by...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

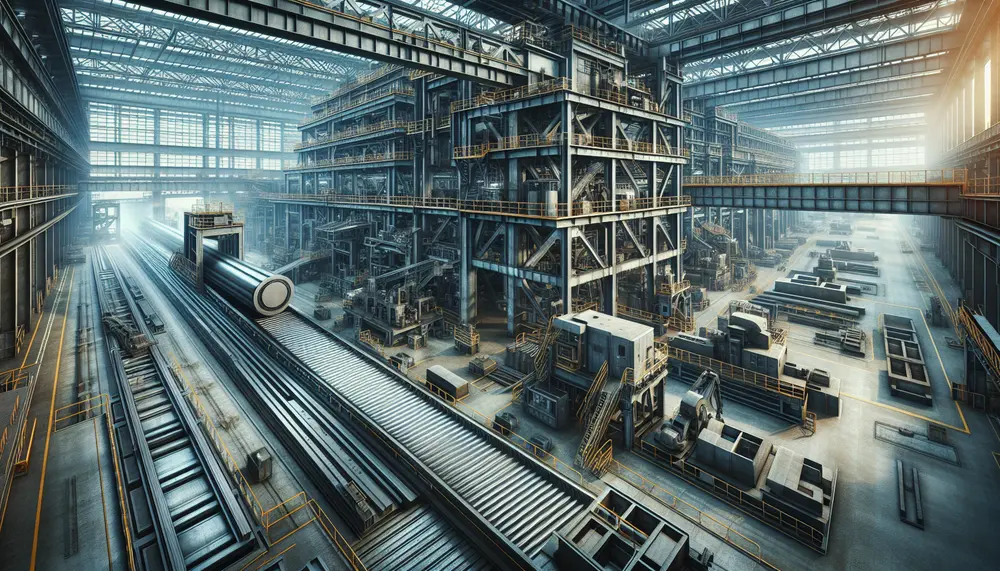

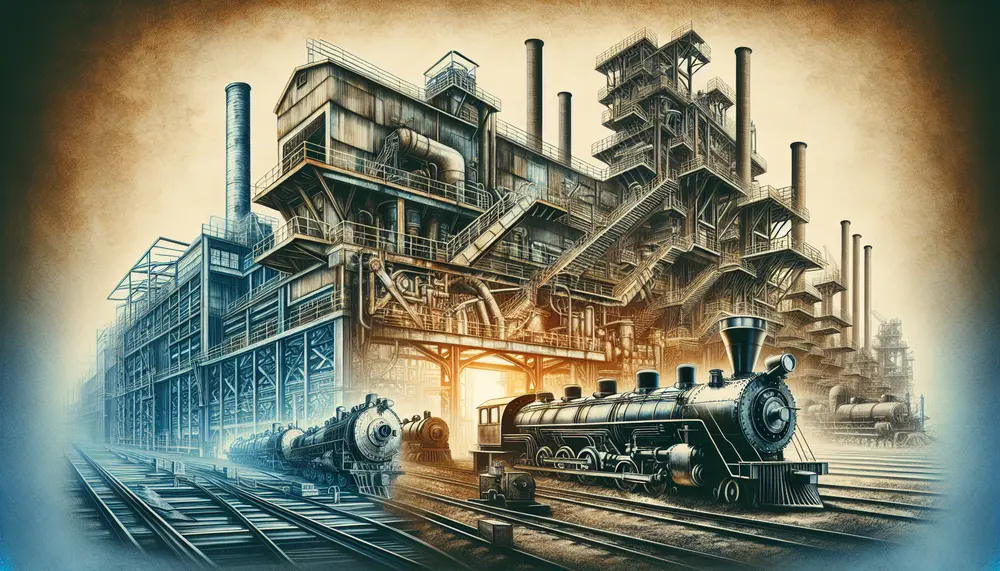

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

The evolution of steelmaking has progressed from labor-intensive early methods to advanced technologies like the Basic Oxygen Steelmaking and Electric Arc Furnaces, enhancing efficiency and sustainability. The once-dominant Bessemer Process was superseded due to its limitations in controlling chemical composition...

ArcelorMittal's steel making process combines traditional methods with advanced technologies, focusing on sustainability and efficiency. The company continuously innovates to improve quality and reduce environmental impact while maintaining a strategic approach to resource management in the global steel industry....