Table of Contents:

Understanding Steel Production in Europe

Steel production is a vital industry that lies at the heart of modern civilization. Europe, in particular, has a rich history and a robust framework when it comes to producing steel. This industry not only supports numerous sectors, including construction, automotive, and infrastructure but also plays a critical role in the economic frameworks of individual countries. To truly understand steel production in Europe, we must delve into the complex processes, the raw materials required, and the economic relevance of this metal to the European market.

The production of steel in Europe is characterized by a diverse range of techniques, from traditional blast furnaces to electric arc furnaces, which recycle scrap metal into new steel. These methods reflect the continent’s commitment to innovation and sustainability, balancing efficiency with environmental responsibility. Moreover, the strategic use of resources such as iron ore and coal, or alternative inputs like recycled steel, underscores the adaptive nature of the European steel industry.

Europe's approach to steel production is also shaped by stringent quality controls and adherence to international standards, ensuring that the steel produced is not only strong and durable but also meets global safety and environmental benchmarks. This focus on quality has solidified Europe's position as a key player in the global steel market, capable of competing with giants such as China and the United States.

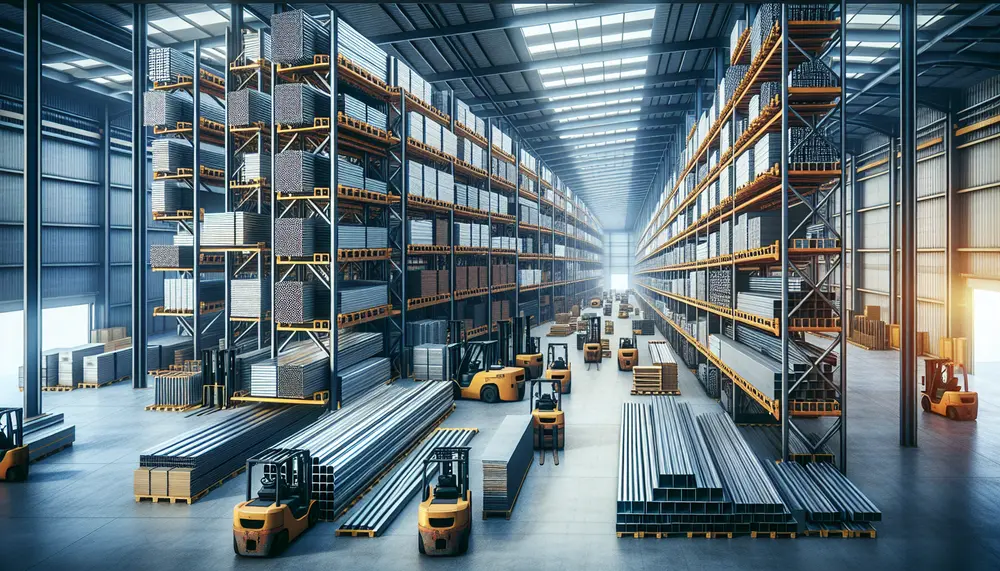

It is essential to recognize the infrastructure that supports European steel production. A network of suppliers, manufacturers, and transport systems work seamlessly to ensure that steel is produced efficiently and reaches its intended markets. Europe's logistical prowess, coupled with its geographic advantage, allows for the swift movement of goods, contributing to the dynamic nature of its steel industry.

In conclusion, the intricacies of steel production in Europe are manifold. With a fine blend of tradition and technology, Europe has carved out a formidable niche in the global steel production landscape. As environmental considerations continue to grow, Europe's steel industry is set to evolve further, ensuring sustainable growth and innovation for years to come.

The Backbone of European Economy: Steel Industry Overview

The steel industry stands as a pillar of economic stability and growth in Europe, interlinking various industrial sectors. Its influence stretches from providing job opportunities to bolstering exports, which vividly highlights the interdependence between the steel sector and the overall economic health of the continent.

Employment within the steel industry is a significant economic driver, directly providing work for hundreds of thousands of individuals across Europe and many more in related sectors. The ripple effects of steel production employment are felt widely, with each job in the sector supporting an estimated seven additional positions in the supply chain and the broader economy.

Europe's steel industry is also a major contributor to the continent's trade balance. With a significant portion of its production meeting the demand of internal markets, the surplus is exported globally, evidencing the international competitiveness of European steel. The export-driven aspect of the industry not only solidifies economic ties with trading partners but also attests to the quality and innovation inherent in European steelwork.

The steel sector's commitment to progressive environmental policies positions it as a leader in the drive towards a greener economy. European steel manufacturers are at the forefront of reducing carbon emissions, improving energy efficiency, and advancing recycling, all of which contribute positively to the environmental footprint of the industry and resonate with the European Union’s climate objectives.

A robust regulatory framework supports the industry, with policies designed to foster competition, ensure fair trade, and encourage investment in new technologies. This framework ensures that the steel sector remains resilient against external pressures and market fluctuations, ready to adapt and thrive in an ever-changing global landscape.

In sum, the steel industry constitutes the backbone of the European economy through its intrinsic role in job creation, trade, environmental stewardship, and regulatory advancement. This symbiotic relationship between steel production and economic vigor underscores the critical nature of the industry's sustained health and prosperity.

Key Players: Leading Countries in European Steel Production

Within the European steel sector, certain nations stand out for their substantial contributions to the continent's overall production capacity. These key players are not only central to Europe's steel output but also influence the global steel landscape with their industrial prowess.

| Country | Annual Steel Production (Million Tonnes) |

|---|---|

| Germany | XX.X |

| Italy | XX.X |

| France | XX.X |

| Spain | XX.X |

| Poland | XX.X |

Note: The exact figures are subject to change and should be updated according to the latest data available.

Germany stands at the forefront, not only as Europe's largest economy but also as its leading steel producer, setting benchmarks in quality and efficiency. Following Germany, countries like Italy and France offer significant contributions, benefiting from their rich industrial histories and modernized production methods.

Spain and Poland also play important roles, with their steel production facilities continuously improving through technological advancement and strategic investments. The combined efforts of these nations contribute a significant part of Europe's steel, underpinning the region's industrial strength and its capacity to meet both domestic and international demand.

While these countries are the front runners, several other European nations also contribute to the diversity and strength of the overall steel industry, each with unique attributes and specialized production capabilities. The collective ensemble of these nations fortifies Europe's standing in the world's steel production arena.

"The European steel industry is the sum of its parts, with each member country providing a unique contribution to a collective strength that extends far beyond borders."

Innovation and Technology: Advancements in European Steel Manufacturing

European steel manufacturing stands at the cutting edge of technological innovation and development. As the industry advances, embracing new technologies has become a hallmark of European manufacturers, positioning them as leaders in efficient and sustainable steel production.

Digitalization and automation have revolutionized the steel production process, with smart factories utilizing artificial intelligence (AI) and machine learning to optimize operations. These advancements contribute immensely to precision, waste reduction, and energy efficiency, further enhancing the competitive edge of European steel manufacturers.

Advancements in material science have led to the development of new steel alloys with superior properties, catering to the specific needs of industries such as aerospace, automotive, and renewable energy. Moreover, the integration of 3D printing into the fabrication process has opened up innovative pathways for designing and manufacturing custom steel components with intricate geometries and tailored characteristics.

Europe's commitment to sustainability has spurred the expansion of green steel production methods, which aim to significantly reduce carbon dioxide emissions. This includes the use of electric arc furnaces powered by renewable energy sources and the exploration of hydrogen as an alternative to fossil fuels in the iron reduction process. These forward-looking initiatives demonstrate Europe's dedication to a sustainable industrial future.

The synergy between academia and industry has been pivotal in fostering an environment conducive to research and development within the steel sector. Collaborations between universities, research institutions, and steel companies have resulted in numerous breakthroughs, ensuring a continuous pipeline of innovative solutions to both current and future manufacturing challenges.

"Through relentless pursuit of innovation and technology, European steel manufacturing is not just reinventing its processes, but also redefining the very boundaries of what is possible with this quintessential material."

Environmental Impact and Sustainability in Steel Production

As the world increasingly focuses on environmental sustainability, the steel industry faces immense pressure to minimize its ecological footprint. Europe has been at the forefront of this movement, with steel producers actively pursuing methods to lessen the environmental impact of their operations.

One significant stride has been the implementation of energy-efficient technologies, which aim to curtail greenhouse gas emissions inherent in steel production. Initiatives include the recovery of waste heat for power generation and the adoption of ultra-low emission technology in steel mills, contributing to a marked reduction in the industry's carbon output.

Resource management is another key aspect, with many European steel producers adopting material recycling practices. Steel is one of the most recyclable materials on the planet, and effective recycling significantly diminishes the demand for raw materials, thus conserving natural resources and energy.

In light of carbon reduction goals, investment in the research of alternative methods of production has soared. Innovations such as the use of hydrogen in direct reduction plants are being explored, with the potential to revolutionize the industry by eliminating the need for carbon-based reduction agents entirely.

Moreover, certification systems and eco-labeling have become more prevalent, allowing consumers to identify products made with environmentally friendly steel. This transparency not only educates consumers but also drives the industry towards more sustainable practices to meet customer expectations.

Ultimately, the transition to sustainable steel production is multifaceted, requiring collaboration across governments, industry players, and consumers. These eco-conscious initiatives reflect not only regulatory compliance but also a broader commitment to protecting our planet for future generations.

"Investing in the planet: European steel producers are forging a path to a greener future, balancing economic growth with environmental stewardship."

Challenges and Opportunities for Steel Producers in Europe

The European steel industry, while robust, is not without its challenges. Producers face various obstacles that require strategic navigation to ensure long-term viability and success. However, where there are challenges, there also lie opportunities for growth and innovation.

Market volatility presents a significant challenge as fluctuations in global demand, and prices can impact profitability. European steel producers must remain agile, adapting to market changes swiftly to maintain their competitive edge. Opportunities arise in developing flexible business models and investing in market analysis to predict and respond to these fluctuations promptly.

Competition from international producers, particularly those from regions with lower production costs, can undercut European markets. Producers must emphasize the high quality, sustainability, and technological superiority of European steel to compete effectively. Additionally, there is an opportunity to explore niche markets and specialized products where European producers can lead.

Regulatory pressure also poses a challenge, with stringent environmental policies requiring producers to invest in cleaner technologies. These regulations spur innovation, as they push companies to explore new methods of production that are both efficient and environmentally friendly, thereby unlocking new markets and consumer segments focused on sustainability.

The supply of raw materials is a constant concern, with geopolitical factors affecting accessibility and cost. European steel producers have the opportunity to invest in recycling initiatives and local sourcing to mitigate these risks and improve supply chain resilience.

Lastly, staying at the forefront of technological advancements is a continual challenge that demands considerable investment in research and development. This challenge is also an opportunity to lead in the development of next-generation steel products and production processes, which can provide a substantial competitive advantage in the global market.

"While challenges indeed shape the landscape of Europe's steel industry, they also serve as catalysts for progress, pushing producers towards innovation and excellence that can redefine the industry's future."

The Future of Steel: Trends and Predictions for European Production

The horizon for European steel production is both exciting and challenging, with emerging trends shaping the trajectory of the industry. Predicting these trends is key for steel producers to prepare and adapt for the future, ensuring continued relevance and success.

Digital transformation is expected to continue at an accelerated pace. Smart manufacturing and Industry 4.0 are set to deepen their impact on production processes, with data analytics and cyber-physical systems becoming standard in optimizing operational efficiency and product quality.

The shift towards low-carbon steelmaking processes is projected to gain considerable momentum. As the global community intensifies its focus on climate change, European producers are likely to ramp up their efforts in deploying green technologies and minimizing carbon footprints.

Another growing trend is the demand for high-strength and lightweight steel, particularly by the automotive and construction industries. This demand drives innovation in material science, leading to the development of advanced steel grades that can meet these specific industry needs while maintaining sustainability benchmarks.

Circular economy principles are set to play a larger role, with an increasing emphasis on recycling and material efficiency. The full life-cycle assessment of steel products will likely become more prevalent, from production to end-of-life recycling, creating a closed-loop system that reduces waste and conserves resources.

Geopolitical and economic factors will continue to influence the industry, with trade policies and international relations affecting access to markets. Producers may seek to build more resilient supply chains and consider strategic alliances to navigate these complex landscapes.

"The steel industry of tomorrow calls for a blend of tradition and innovation — embracing upcoming trends while remaining grounded in the fundamental strengths that define European steel production."

How Europe Compares: Global Steel Production Insights

In the global arena of steel production, Europe maintains a significant presence, marked by its long industrial heritage and capacity for innovation. A comparative analysis with other leading regions presents a broader view of Europe's role in the worldwide steel industry.

Asia, with countries like China and India, leads in sheer volume of steel production, driven by rapid industrialization and expansive construction projects. China, in particular, is the world's largest steel producer, accounting for a sizeable percentage of global output. This highlights a contrast with Europe's focus on quality, sustainability, and advanced manufacturing techniques.

- Production Capacity: While European steel production does not match Asia's volume, it compensates with high standards and innovation.

- Technology and Innovation: European producers are at the vanguard of incorporating new technologies and sustainable practices, often setting global benchmarks.

- Quality of Steel: Europe is renowned for producing steel of exceptional quality, with rigorous adherence to safety regulations and environmental standards.

- Sustainability Efforts: The European commitment to sustainability is strong, with ambitious goals to reduce carbon emissions and incorporate renewable energy sources.

- Regulatory Environment: Europe has a strict regulatory framework, focused on fair competition and environmental protection, offering a balance between economic development and ecological preservation.

North America and other advanced economies share several similarities with Europe in terms of quality and regulatory standards. However, Europe often leads in regulatory frameworks and pushes the envelope in greener production initiatives.

The South American and African regions are emerging players in the steel industry, with potential for significant growth. Europe can leverage its experience and technology to forge collaborative efforts and investment opportunities in these markets.

"Positioned within a complex global tapestry, European steel production stands out for its commitment to quality, sustainability, and innovation, influencing industry standards and practices worldwide."

Steel Production Europe: A Statistical Analysis

The landscape of European steel production can be quantified through a statistical analysis, reflecting its scale, growth, and contribution to the global industry. By examining these numbers, we gain a clearer understanding of Europe's steel production capabilities and position in the world.

Data sourced from renowned industry bodies such as the World Steel Association provides an authoritative perspective on production volume over the years. For instance:

| Year | Steel Production in Europe (Million Tonnes) |

|---|---|

| 2009 | XX.X |

| 2010 | XX.X |

| 2011 | XX.X |

| 2012 | XX.X |

Note: The figures are demonstrative and should be updated with the latest available data.

This historical data illustrates trends in output that could be influenced by various factors, including economic cycles, market demand, and technological advancements. Analyzing these trends can provide valuable insights into the forces that shape the European steel industry.

Furthermore, country-specific analysis within Europe reveals disparities in production capabilities and specializations, offering a granular look at how different nations contribute to the continent's steel output. Such data can help identify leaders in production and innovation, as well as emerging markets within the European Union and neighboring regions.

Comparisons of productivity per capita, energy consumption, and yield rates offer additional dimensions to the statistical landscape, pinpointing areas of efficiency and opportunity for improvement.

"Statistics serve as the foundation for strategic decisions in the European steel industry, providing a factual base from which to chart future initiatives and respond to the ever-changing economic environment."

The Role of Policy and Regulation in Shaping European Steel Industry

The foundation and progression of the European steel industry are heavily influenced by the intricate web of policies and regulations that govern it. These frameworks are crucial for maintaining a level playing field, fostering innovation, and ensuring sustainable development within the sector.

Policies emanating from the European Union play a pivotal role in steering the industry. Trade policies, for example, help protect against unfair imports that could potentially harm domestic production. Tariffs and anti-dumping measures are tools frequently employed to safeguard the European steel industry's integrity and competitiveness.

Environmental regulations, particularly those associated with carbon emissions and energy usage, are becoming increasingly stringent. The European Union's Emissions Trading System (ETS) is an example of a regulatory mechanism that holds producers accountable for their carbon output, promoting greener production methods and energy efficiency.

Investment in research and development is encouraged through various incentives and programs. These government-led initiatives facilitate the adoption of cutting-edge technologies and the exploration of new market opportunities, ensuring the industry's evolution in line with modern advancements.

Labor and safety regulations are other areas where policy significantly impacts the industry. Standards for worker safety and health ensure that the steel production environment remains secure and compliant with the best practices, benefiting employees and companies alike.

Consumer protection laws, ensuring product quality and reliability, foster trust in European steel, both domestically and internationally. This regulatory framework contributes to the high-standing reputation of European steel products on the global stage.

"Policy and regulation serve as the guiding lights for the European steel industry, providing the strategic direction needed to navigate through the challenges of modern industry while upholding the highest standards of quality, safety, and environmental responsibility."

Building a Stronger Europe: The Importance of Steel Trade and Export

The steel industry is a key contributor to the economic fortitude of Europe, with trade and export activities being pivotal elements. The exchange of steel commodities not only bolsters Europe's trade balances but also reinforces its strategic position in global markets.

European steel is valued globally for its premium quality and adherence to stringent environmental and safety standards. The export of steel to countries outside the European Union promotes the continent's technological and sustainable manufacturing practices, and in turn, serves as a soft power tool, solidifying Europe's reputation as a leader in industrial innovation.

Diversifying export destinations stands as a strategic priority for European steel producers. By expanding into emerging and established markets, producers can mitigate the risks associated with reliance on any single region and take advantage of growth opportunities worldwide.

Free trade agreements, when structured fairly, can be instrumental for the steel industry, reducing barriers to entry and fostering mutually beneficial relationships. These agreements must be crafted to prevent the infringement of European market space by lower-priced imports that can compromise domestic production.

Consistent with the spirit of solidarity that the European Union promotes, the success of the steel industry in trade and export not only benefits individual companies but also the wider European economy. It supports associated industries, enhances job creation, and contributes to overall economic growth.

"Exporting not just goods but also values, Europe's steel trade is a testament to the continent's commitment to quality, innovation, and collaborative economic progress."

Case Studies: Success Stories in European Steel Production

The narrative of European steel production is rich with success stories that exemplify the industry's adaptability, resilience, and innovation. Case studies of these achievements provide valuable insights and inspiration for the sector.

- Innovative Steel Alloys: A renowned European steel company introduced a new, high-strength alloy that revolutionized the automotive industry, allowing for lighter, more fuel-efficient vehicles without compromising on safety or performance.

- Green Production Initiatives: Another success story involves a mill that became the pioneer in utilizing renewable energy sources, significantly reducing its carbon footprint while maintaining a high output of quality steel.

- Technological Advancements in Manufacturing: Demonstrating the potential of smart manufacturing, one European plant achieved notable increases in efficiency and reduction of waste by integrating IoT devices and real-time data analytics into their process flows.

- Strategic Trade Partnerships: The strategic establishment of robust trade partnerships allowed a medium-sized steel producer to expand its market reach, allowing it to thrive even during periods of domestic economic downturn.

- Adaptive Business Models: A European steel producer remained agile in the face of rapidly changing global markets by adopting a flexible business model, diversifying its product line to tap into emerging market demands successfully.

These case studies underscore the creativity and business acumen that exists within Europe's steel industry. They reflect how innovative thinking, combined with a commitment to sustainability and cutting-edge technology, leads not only to survival but to success in a competitive global landscape.

"Inspired by the past, informed by the present, European steel producers continue to forge success stories that resonate across the globe and define the future of the industry."

Steel Production Europe: Ensuring Quality and Standards

The European steel industry is synonymous with quality and adherence to the highest standards. Through rigorous processes and meticulous oversight, European steel producers ensure their products meet and often exceed the required specifications for various applications.

Certification bodies play a crucial role in this regard. Organizations such as Eurofer and the European Committee for Standardization (CEN) provide certifications and standards that European steel producers strive to meet. These standards cover a wide range of criteria, including material properties, production processes, and environmental impact, ensuring that European steel stands out in the global marketplace.

Continuous monitoring and testing of steel properties, such as tensile strength, ductility, and corrosion resistance, are integral to the quality assurance process. This attention to detail not only satisfies regulatory requirements but also instills confidence in consumers and end-users of European steel products.

Investment in state-of-the-art laboratories and research institutions allows for ongoing improvement and innovation in steel quality. European steel producers leverage these resources to push the boundaries of what is achievable with steel, exploring new compositions and treatment processes that advance the material's performance.

In addition, comprehensive training programs ensure that the workforce within the European steel industry is highly skilled. Knowledgeable employees are key to maintaining the quality and standards that the world has come to expect from European steel.

"Dedication to excellence is at the core of the European steel industry's ethos, with quality and standards serving as the unwavering pillars that uphold its global reputation."

The Economic Significance of Steel Production in Europe

The steel industry is a cornerstone of the European economy, providing a fundamental material that drives growth and development across a myriad of sectors.

The economic contribution of steel production extends far and wide, influencing employment, gross domestic product (GDP), and trade. The industry directly and indirectly supports numerous jobs across the continent, from those in the manufacturing plants themselves to roles in related fields such as transportation, construction, and engineering. These employment opportunities are critical for local economies and contribute to the economic health of nations.

Steel production is integral to the infrastructure development that underpins economic activity. It provides the materials necessary for building everything from transportation networks to high-rise buildings, all of which facilitate economic expansion and urban development. The strength and versatility of steel make it indispensable in modern construction, energy production, and manufacturing.

In terms of trade, steel production is a heavyweight contributor to Europe's balance of trade. European steel is exported across the globe, bringing in revenue and showcasing European industrial prowess on the world stage. Moreover, the export of steel often has a multiplier effect, boosting related industries and services.

Furthermore, the steel industry supports innovation and technological advancement. Investments in research and development lead to new applications for steel, expanding its uses and creating new markets for European producers to explore.

"Steel is not just a material but a vital component of Europe's economic engine, its production fueling progress, prosperity, and possibility across the continent."

Conclusion: The Steel Thread in Europe's Growth and Development

As we have explored the multifaceted aspects of steel production in Europe, it is clear that steel forms a continuous thread running through the fabric of Europe's growth and development. The industry's impact on the economy, innovation, employment, and trade underscores its vital role in shaping the future of the continent.

European steel production, with its emphasis on quality, innovation, and sustainability, is poised to tackle the challenges of the modern era while seizing the opportunities of a rapidly evolving global landscape. Producers remain committed to advancing manufacturing technologies, adopting sustainable practices, and driving economic growth, all of which contribute to the continent's competitiveness on the world stage.

As policies and regulations evolve to further support these endeavors, and as trade and export continue to forge economic ties, the European steel industry is set to remain a dynamic, integral force in the global marketplace. With each stride in technology and sustainability, Europe strengthens its legacy as a leader in steel production, ready to meet the demands of the future with resilience and vigor.

"Steel production is more than just an industry in Europe—it is a testament to the continent's ingenuity, strength, and unwavering resolve to build a robust and prosperous future."

FAQ: Insights into Steel Production in Europe

What are the primary methods of steel production used in Europe?

Europe employs both traditional blast furnaces and electric arc furnaces for steel production. Blast furnaces are used for large-scale steel production using iron ore and coke, while electric arc furnaces recycle scrap steel into new steel, emphasizing sustainability and efficiency.

Which countries are the leading producers of steel in Europe?

Germany, Italy, and France are among the top producers of steel in Europe. These countries have significant industrial infrastructures and contribute vastly to Europe's steel output, leveraging their rich histories and modern technologies in steel manufacturing.

How does Europe's steel production compare with global trends?

Europe's steel production is known for its high quality and sustainability standards, distinguishing it from other regions. While Europe may not lead in volume compared to Asia, its focus on innovation and environmental responsibility sets a benchmark for the global steel industry.

What role does technology play in the advancement of steel production in Europe?

Europe is at the forefront of technological advancement in steel production, with a strong emphasis on digitalization, automation, and the development of sustainable production methods. European manufacturers are invested in continuous innovation, including the use of AI, to improve efficiency and reduce environmental impact.

What steps are European steel producers taking to ensure sustainability?

European steel producers are actively pursuing energy-efficient technologies, emission reduction initiatives, and recycling programs. Investments in renewable energy sources, the exploration of hydrogen in steel production, and adherence to strict environmental regulations are key measures to achieve sustainability goals.