Posts on the Topic Industry

The transformation of steel production, marked by innovations like the Bessemer Process and later advancements, revolutionized industries by enabling faster, cheaper, and higher-quality steel manufacturing. These breakthroughs fueled industrial growth, urbanization, modern infrastructure development, and laid the foundation for a...

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

The US steel industry has evolved from traditional methods to sustainable practices, focusing on recycling and technological innovation, with key players like Cleveland-Cliffs and Nucor leading advancements. Despite challenges such as international competition and environmental regulations, the industry remains a...

The green steelmaking process aims to reduce the significant CO₂ emissions from traditional steel production by utilizing cleaner technologies and renewable energy sources, including hydrogen. This transition involves optimizing existing processes, adopting new sustainable methods, and fully integrating green hydrogen...

Trading and logistics are essential in the steel industry, involving buying/selling products and managing their transportation/storage to ensure efficient movement from producers to consumers. Efficient trade logistics reduce costs, improve delivery times, enhance customer satisfaction, and help companies comply with...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

Becoming a steel making operator involves overseeing the production of steel, ensuring quality and safety standards, and requires technical skills, attention to detail, problem-solving abilities, physical stamina, communication skills, and safety awareness. Educational requirements typically include a high school diploma...

Green steelmaking aims to produce steel with minimal environmental impact by using innovative technologies and renewable energy sources, significantly reducing carbon emissions. Traditional methods rely heavily on fossil fuels and generate substantial CO2, whereas green alternatives like hydrogen-based reduction, electric...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

Steelmaking without coal, utilizing electricity and hydrogen from renewable sources, offers a sustainable alternative to traditional methods by reducing carbon emissions. The shift towards green steel production is driven by innovations like electric arc furnaces and low-carbon materials, with industry...

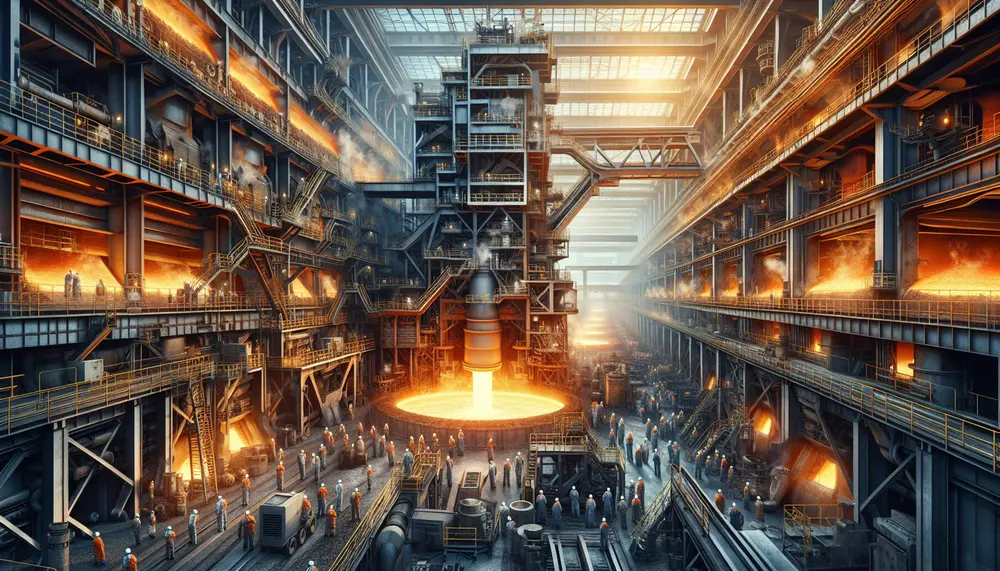

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

Steelmaking, particularly through traditional blast furnace methods, significantly contributes to environmental degradation by emitting greenhouse gases like CO2 and other pollutants. Transitioning to greener technologies such as Electric Arc Furnaces (EAF) could reduce these emissions but requires substantial investment and...

Sustainable steel production aims to minimize environmental impact through energy conservation, increased recycling, and innovative technologies like electric arc furnaces and hydrogen use. The industry faces challenges such as high energy consumption and carbon emissions but is exploring eco-friendly innovations...

Steel production in France has grown due to technological advancements, increased demand, and strategic investments despite challenges like environmental regulations and market volatility. The industry's history shows a pattern of expansion post-WWII, peak production in the 1970s, followed by decline...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...