Posts on the Topic Blast-furnace

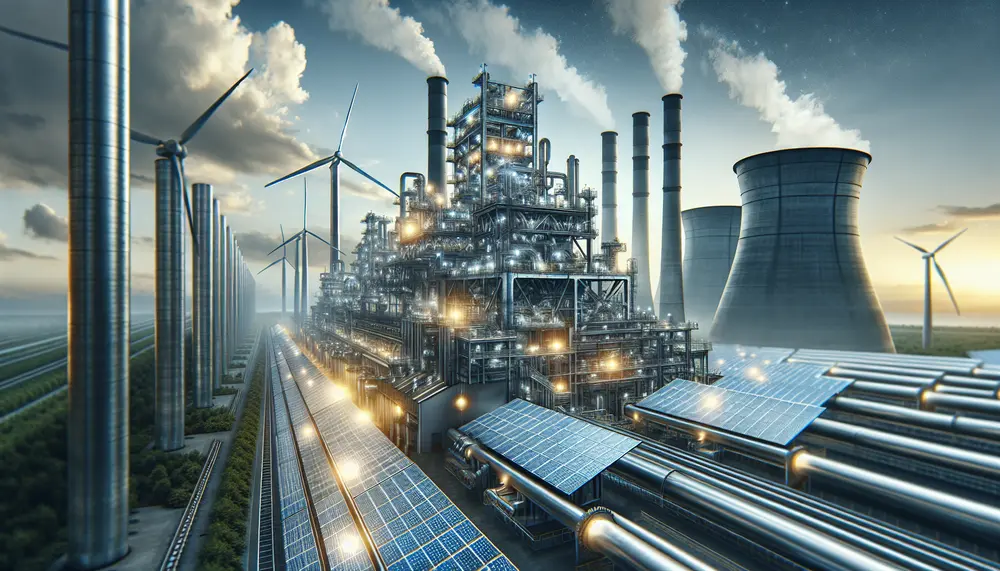

Steel manufacturing transforms raw materials like iron ore into robust steel products through a complex process involving chemistry, physics, and engineering. This journey from ancient methods to modern techniques includes steps such as blast furnace operations and refining processes, highlighting...

The article discusses the importance of visual imagery in understanding and appreciating the steel making process, highlighting how photography can capture each stage—from raw material handling to finishing—and transform industrial scenes into compelling art. It emphasizes that high-quality images not...