Posts on the Topic Steelmaking

Vacuum Tank Degassing (VTD) revolutionizes steelmaking by delivering ultra-pure, high-performance steels with superior mechanical properties and process flexibility. Its adoption drives innovation across industries like automotive, energy, and medical devices while digital monitoring boosts efficiency and traceability....

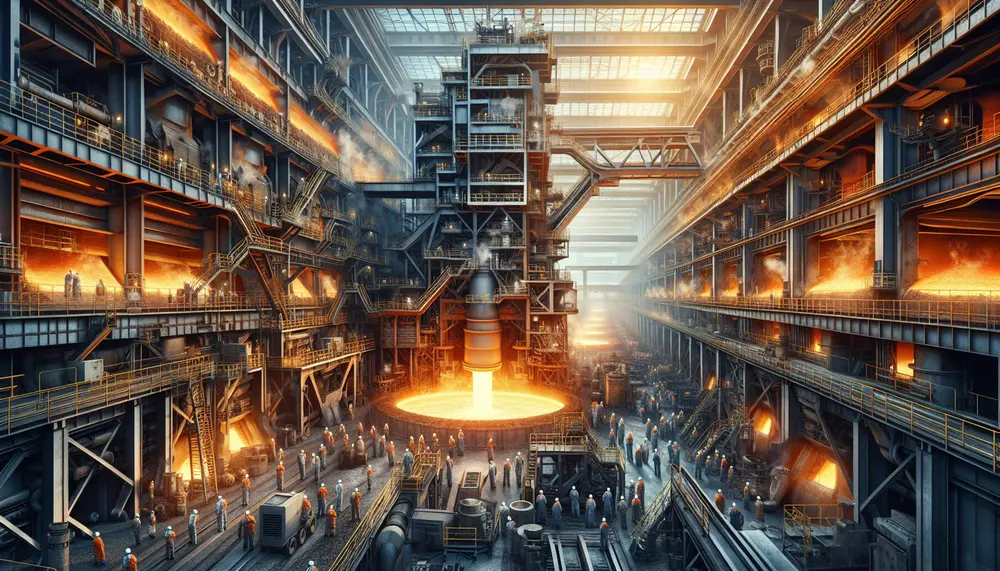

Steelmaking is vital to modern civilization, driving economies, infrastructure development, and sustainability efforts. The industry relies on two main methods—Blast Furnace (BF) for large-scale production with higher emissions and Electric Arc Furnace (EAF) for flexibility and lower environmental impact—shaping a...

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The article provides a detailed overview of the steelmaking process, highlighting key components like raw materials, energy sources, and advanced technologies. It explains primary methods (BOF and EAF), step-by-step production stages, and emphasizes sustainability and innovation in modern steel manufacturing....

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Steelmaking combines science and engineering to transform raw materials into tailored steel products through precise control of temperature, composition, and reactions. Its evolution reflects human innovation, from ancient smelting techniques to modern sustainable methods driven by advanced theoretical principles like...

Nucor revolutionizes steelmaking with its Electric Arc Furnace (EAF) process, transforming recycled scrap into high-quality steel while prioritizing sustainability and efficiency. This innovative approach reduces carbon emissions, enhances energy efficiency, and offers tailored solutions for industries like automotive and construction....

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

CFD steelmaking jobs are on the rise, offering a blend of technology and metallurgy to optimize processes in the steel industry through simulations that enhance efficiency and sustainability. Professionals in this field require technical proficiency, software expertise, analytical skills, problem-solving...

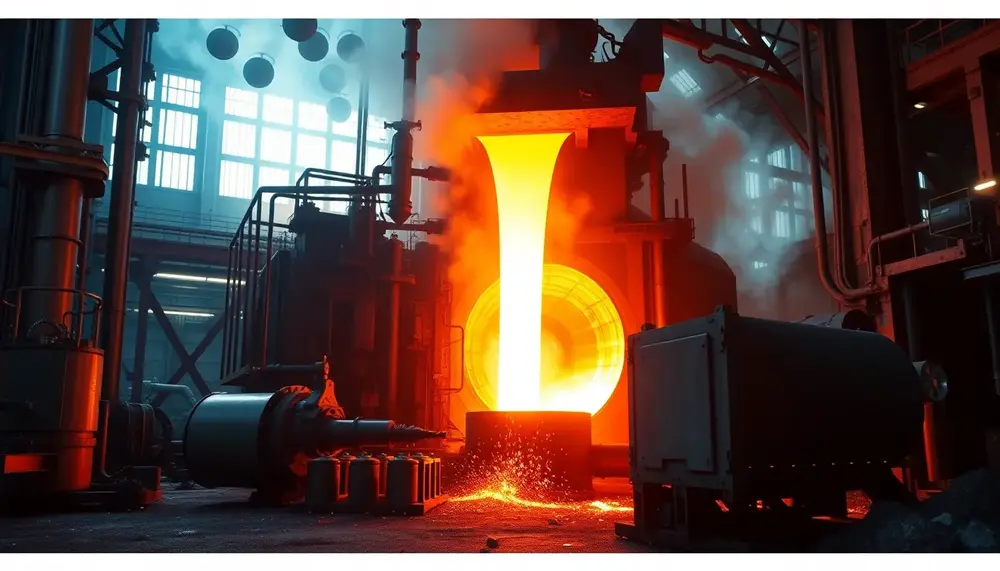

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....