Table of Contents:

Understanding the Roots of Steelmaking: A Historical Overview

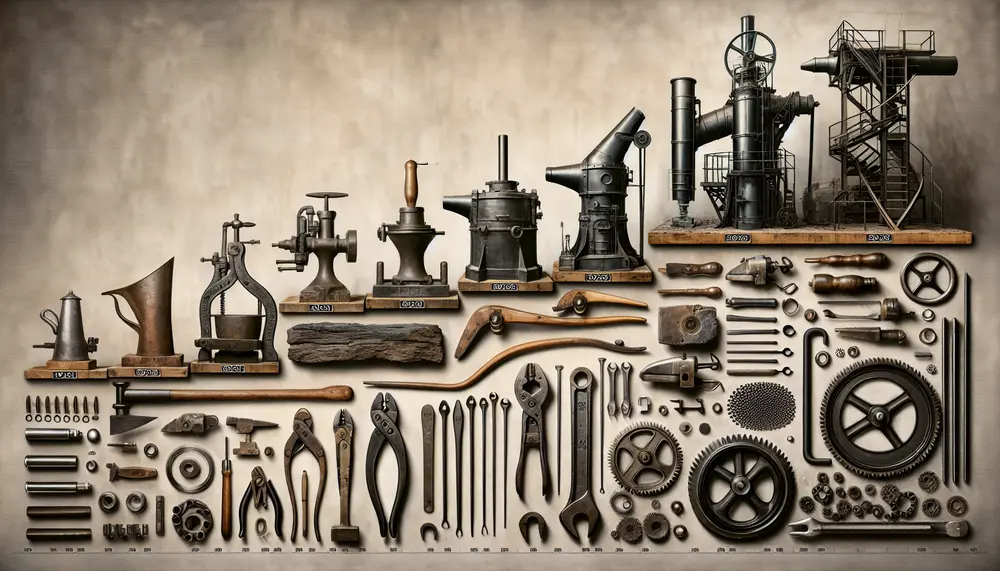

The journey of steelmaking has been a transformative saga, punctuated by numerous innovations and milestones that reshaped civilization. To comprehend the roots of steelmaking, one must delve into the distant past, where the manipulation of iron laid the foundation for the steel industry. Initially, iron was valued for its relative rarity and malleability, which allowed early smiths to forge tools and weapons superior to those made from bronze.

However, iron had limitations, which propelled the quest for a stronger and more versatile material. This quest intensified during the 17th century, with the proliferation of ironwork and the need for more resilient materials. The pivotal historical period that gave rise to steelmaking saw metallurgists and innovators relentlessly pursuing methods to improve iron's properties, eventually culminating in the breakthrough of the steelmaking process.

As we look back on the steelmaking historical period, it becomes clear that the evolution of steel was not merely about the material itself but also about the progress it signified for industry and society at large. The transition from iron to steel marked a new epoch, underscoring the material's significance in the march of human progress.

The Birth of Modern Steelmaking: The Bessemer Process

The industrial revolution paved the way for a myriad of innovations, none more transformative than the creation of the Bessemer process. This groundbreaking technique, introduced by Henry Bessemer in 1856, revolutionized how raw iron was converted into steel. Bessemer's pioneering method involved blowing air through molten pig iron to oxidize excess carbon and other impurities, producing a stronger and more workable metal.

"I had an object in view, moreover, than mere reduction in cost. My highest ambition was to find out some process or mechanical operation which should be capable of reducing iron in great masses from the ore..." - Henry Bessemer, "Sir Henry Bessemer, F.R.S.: An Autobiography"

This innovation in steelmaking marked a significant leap forward, effectively setting in motion the era of mass production of steel. The surge in steel availability had widespread impacts, most notably in the construction of railways, bridges, and skyscrapers, thus catalyzing the expansion of modern infrastructure.

The Bessemer process' contribution to the steelmaking historical period cannot be overstated. It not only enhanced the quality and durability of steel but also democratized its use, transitioning steel from a luxury to a cornerstone of industrialization.

Key Technological Advances in Steel Production

The timeline of steel production is rich with technological ingenuity that has dramatically enhanced the efficiency and quality of steel. Following the Bessemer process, the industry witnessed the advent of the open hearth furnace, which introduced a method where steel was produced from a combination of raw materials, including pig iron, iron ore, and scrap metal, in a regulated manner. This technology excelled at controlling the chemical composition of steel, thereby refining its characteristics for different applications.

Another substantial advancement was the development of the electric arc furnace (EAF). This innovation enabled the melting of large quantities of scrap steel using high-power electric arcs, a process that augmented the recycling aspect of steel production and lent itself to the crafting of specialized high-grade steels.

| Technological Advance | Impact on Steel Production |

|---|---|

| Open Hearth Furnace | Enhanced control over steel's chemical composition and properties. |

| Electric Arc Furnace (EAF) | Facilitated the recycling of scrap and production of high-grade steels. |

The continuous casting process, a stark departure from the classic batch casting methods, also revolutionized steelmaking. By streamlining the transfer of molten steel directly into molds, this method virtually eliminated the need for laborious and costly intermediate steps, thus improving yield and energy efficiency. These advancements not only refined the properties of steel but also brought about significant economic and environmental benefits to the steelmaking industry.

The Rise and Fall of British Dominance in Steelmaking

Britain's supremacy in the steelmaking industry during the 19th century was a testament to its industrial prowess. Innovations like the Bessemer process were largely driven by British ingenuity, cementing the nation's position as a leader in a booming industry. However, this dominance was not to persist indefinitely.

As other nations embraced and refined new methods of steel production, Britain's share of the global market began to dwindle. Competitors, notably Germany and the United States, invested heavily in the open hearth process and electric arc furnace technology, surpassing the production capacity and efficiency of British mills.

- Britain's early lead due to pioneering methods.

- Global competition rises with advanced processes.

- Decline in British market share and industry influence.

Late in adapting to newer technologies, such as the basic oxygen process, which further streamlined steel production, British companies struggled to keep up. Economic pressures, outdated facilities, and foreign competition led to a significant contraction of the British steel industry, necessitating government intervention and nationalization in an attempt to salvage it.

This nationalization, however, proved to be a complex and contentious solution, subject to the political climate and philosophies of succeeding governments. By the late 20th century, the industry had transitioned through phases of privatization and re-privatization, struggling to regain its former stature in a vastly changed global landscape.

The Impact of World Wars on Steel Industry Dynamics

The World Wars represented periods of extraordinary demand and progression for the steel industry. These global conflicts necessitated vast quantities of steel for military hardware, vehicles, and infrastructure, leading to a surge in production and innovation to meet the urgent needs.

During World War I, the steel industry's capacity was pushed to new limits as governments prioritized war material over commercial production. Steel mills across the world expanded rapidly, with governments facilitating the increase in output through financial and policy support.

World War II further accelerated the industry's growth and technological development. Steel was the backbone of the war effort, with countries on all sides of the conflict racing to optimize their production processes to out-manufacture their adversaries. This period saw the implementation of strategic resource management and the widespread use of more efficient steelmaking technologies, including advanced rolling techniques and quality control measures.

- Steel demand skyrocketed due to military needs.

- Rapid expansion and state intervention bolstered industry capability.

- Technological advancements driven by wartime exigencies.

The post-war period brought about significant shifts as the industry transitioned from a wartime economy to a peacetime one. The accumulated advances and expanded capacities led to a more competitive global steel market, with new challenges arising in terms of overproduction, international trade, and the need for modernization to address changing demands.

Nationalization and Privatization: Shaping the British Steel Sector

The fluctuating fortunes of the British steel sector were heavily influenced by governmental policy decisions regarding nationalization and privatization. The post-World War II landscape saw nationalized industries as a means to rebuild a ravaged nation's economy, leading to the Iron and Steel Act of 1949, which took effect with the nationalization of British steel in 1951.

The state's control over this critical industry aimed to streamline production, allocate resources efficiently, and stabilize employment. However, nationalization was a contentious issue, subject to the swings of political sentiment and economic philosophy that changed with successive administrations.

In the 1980s, the landscape shifted once more under the Thatcher government, which embarked on a widespread privatization campaign. The British steel industry, along with other major state-owned enterprises, was returned to private hands. This was viewed as a means to foster competition, drive innovation, and ultimately, improve the industry's global competitiveness. The privatization of the steel sector was also meant to reduce the financial burden on taxpayers and allow market forces to dictate the industry's direction.

- 1949 Iron and Steel Act and subsequent nationalization.

- State control's goals of efficiency and employment stability.

- Privatization as a strategy for competitive improvement.

The impact of these policies is still a matter of debate among economists and historians. Nonetheless, the long-term effect on the British steel sector has been profound, shaping not only the industry's structure but also its role within the broader economy and the international steel market.

The Australian Steel Industry: A Brief Historical Perspective

Although less well-known than its British counterpart, the Australian steel industry also has a rich history that reflects its own unique challenges and achievements. During the 19th century, while several enterprises explored iron production, steel remained a novel commodity, produced on a much smaller scale than in industrial powerhouses like Britain and the USA.

It was not until the early 20th century that the country began to develop a more robust steel industry. This growth was largely fueled by the discovery of extensive iron ore reserves, coupled with the nation’s increasing demand for steel to facilitate its own burgeoning infrastructure projects and economic expansion.

- 19th-century iron production ventures.

- 20th-century expansion due to resource discovery.

- Development driven by domestic demand for steel.

As the Australian steel industry evolved, it faced significant geographic and logistical obstacles, including the vast distances between mines, production facilities, and markets. Nevertheless, Australia established itself as a significant player in the steel market, leveraging its abundant natural resources and adapting to the international steel trade's changing dynamics.

Today, the Australian steel industry is a testament to the country’s ability to overcome its geographic isolation and contribute meaningfully to the global steel supply chain.

The Role of Iron in Paving the Way for Steel

Iron has been a cornerstone in human development, its utility stretching back millennia. This fundamental metal set the stage for the advent of steel, an alloy that has come to define modern construction and engineering. Understanding the transition from iron to steel is crucial in grasping steel's historical importance.

Iron's dominance began during the Iron Age, when it replaced bronze as the material of choice for tools and weapons. Despite this, it was not perfect. Wrought iron, while malleable and tough, lacked the hardness and tensile strength desired for certain applications. Cast iron, on the other hand, was brittle despite its hardness. The limitations of these forms of iron catalyzed the search for a material with the best attributes of both.

- Iron Age: Wrought and cast iron's prevalence and limitations.

- Steel's emergence as an ideal medium, melding strength and ductility.

- Influence on societal progress and industrial innovation.

Steel, with its enhanced characteristics of strength and flexibility, heralded a new era. The transition marked by the invention of steelmaking processes like those created by Bessemer, was significant. It enabled the precise adjustment of iron's carbon content · represented in the formula FexCy, which denotes the varying composition of carbon within iron to create steel · reshaping industries and civilization as a whole.

Thus, while iron gave rise to the development of civilizations, it was the refinement of steel that paved the way for the world as we know it, from towering skyscrapers to vast networks of transportation.

Innovations Post-Bessemer: Open Hearth and Electric Arc Furnace Methods

Following the development of the Bessemer process, the steel industry continued its relentless pursuit of innovation. Two significant advancements were the open hearth furnace and the electric arc furnace methods, each establishing new benchmarks for quality and production efficiency.

The open hearth furnace approach refined the process of fashioning steel from a diverse array of raw materials. By facilitating longer heat durations and allowing for thorough mixing, metallurgists were able to better control the final product's composition. The quality of steel improved, meeting the varying demands of an industrializing world.

On the other hand, the electric arc furnace (EAF) became an essential tool, particularly in utilizing recycled materials. The extreme temperatures generated by electric arcs melted scrap metal efficiently, contributing to sustainable industry practices. This method also provided the versatility needed to create specialized high-grade steels.

"The great advantage of the electric furnace is that heat · a critical agent in metallurgy · can be introduced into the melting chamber without any intermediary..." - Elektrometallurgie by Dr. Richard Taussig

- Open hearth process: Mastery over steel chemistry.

- Electric arc furnace: Sustainability through recycling.

- Both methods' role in meeting specific industry demands.

These innovations symbolized the industry's ability to not just create steel, but to master its properties to the extent required for specific applications, pushing the boundaries of manufacturing and engineering.

The American Steel Giants: Carnegie and the Formation of US Steel

The landscape of the American steel industry was irrevocably changed by the ambitions and entrepreneurship of Andrew Carnegie. At the helm of Carnegie Steel Company, he played a pivotal role in propelling the United States to the forefront of global steel production.

Carnegie's focus on innovation, cost efficiency, and a vertically integrated business model allowed his company to produce large quantities of steel at competitive prices. His success led to significant wealth and established Carnegie as a titan of the industry.

"The way to become rich is to put all your eggs in one basket and then watch that basket." - Andrew Carnegie

Carnegie's eventual sale of his steel company to J.P. Morgan in 1901 resulted in the creation of U.S. Steel, the largest steel producer and the first corporation in the world to have a market cap over one billion dollars. This conglomerate symbolized the might of American industry and served as a blueprint for future corporate growth and consolidation.

- Carnegie's strategic business innovations and efficiencies.

- Vertical integration: Control from raw material to finished product.

- Formation of U.S. Steel and its impact on industry standards.

The formation of U.S. Steel marked a turning point that encapsulated the ambition and industrial capacity of the United States. It was a testament not only to the potential of steelmaking but also to the American Dream, demonstrating the profound economic transformation possible within a rapidly industrializing nation.

The Shift to Oxygen Steelmaking and Its Global Influence

The latter half of the twentieth century saw another pivotal shift in the steelmaking industry with the advent of oxygen steelmaking. This method involved the injection of pure oxygen into molten iron, markedly accelerating the refinement process and reducing impurities more efficiently than previous methods.

Oxygen steelmaking achieved prominence due to its significant advantages in terms of production time and energy consumption. The process was capable of producing high-quality steel in less than an hour, compared to the several hours required by open hearth furnaces. This change significantly reduced the industry's carbon footprint by slashing energy requirements.

The global influence of this shift was profound, as it allowed for rapid expansion in steel production capacity, and became a key driver of economic development in post-war societies. Oxygen steelmaking technology rapidly spread across the world, becoming the standard for steel production in many countries due to its efficiency and cost-effectiveness.

- Introduction of pure oxygen refinement in steel production.

- Reduction in production time and energy consumption.

- Global adoption and economic impact of the technology.

The commitment to oxygen steelmaking proved critical for meeting the growing post-industrial demand for steel, with its impacts still felt in today's steel production landscape.

Steel's Sustainability: Recycling and Modern Developments

Sustainability has become a cornerstone of modern steelmaking practices, with the industry making considerable strides in recycling and environmental responsibility. Steel's inherent durability and recyclability make it a key player in sustainable development. In fact, steel recycling saves enough energy annually to power 18 million households, making a substantial impact on energy conservation.

Modern developments in steel production have increasingly focused on minimizing waste and reducing the industry's environmental footprint. This commitment is reflected in the widespread use of electric arc furnaces (EAF), which predominantly employ scrap steel as a raw material, consuming significantly less energy than traditional blast furnaces.

New steelmaking methods complement these efforts by targeting not just efficiency and cost-effectiveness, but also ecological aspects. Technologies such as advanced high-strength steels (AHSS) help to reduce vehicle weights, thereby contributing to lower greenhouse gas emissions during a vehicle's life cycle.

"Steel is the material of choice for environmental sustainability, in construction, transport, and renewable energy infrastructure." - World Steel Association

- Recycling steel: A testament to the industry's adaptability and sustainability.

- Electric arc furnaces: A beacon of energy efficiency.

- Advancements in steel alloys like AHSS for greener applications.

With its ongoing commitment to innovation, the steel industry continues to forge paths toward a more sustainable and responsible manufacturing era, recognizing its role in building a greener future.

The Current State of Steelmaking and Future Outlook

Today's steelmaking landscape is characterized by a blend of tradition and innovation, with industry leaders pushing the frontiers of technology, efficiency, and environmental stewardship. The global demand for steel continues unabated, propelling further advancements in production methods that prioritize speed, quality, and ecological impact.

The latest practices in the industry reflect a shift towards more sustainable and smart manufacturing processes. Companies are utilizing techniques such as machine learning and AI to optimize production and reduce waste, as well as investing in research to lower carbon emissions associated with steelmaking.

Looking to the future, the industry is poised to embrace breakthroughs such as hydrogen-based steelmaking, which offers the potential of near-zero carbon emissions. Coupled with the ongoing enhancements in electrical steel used in energy generation and transmission, these developments signify a promising horizon for the industry.

"In the journey to carbon-neutral steelmaking, it's not just about the steel itself but the entire value chain." · Industry Expert

- Adoption of cutting-edge technologies for efficiency and sustainability.

- Investments in carbon-reducing and energy-saving innovations.

- Prospects of hydrogen and electric advancements in steel production.

The steel industry's trajectory indicates a continued commitment to innovation and sustainability, ensuring its pivotal role in modern society while actively working towards a greener future.

Frequently Asked Questions About the History of Steelmaking

What was the Bessemer Process and why was it important?

The Bessemer Process was a steel production method invented by Henry Bessemer in 1856, which involved blowing air through molten pig iron to oxidize excess carbon and other impurities. It was a crucial development because it allowed mass production of steel, which was stronger and more affordable than iron, leading to widespread industrial applications.

How did open hearth and electric arc furnace methods contribute to steelmaking?

Open hearth furnaces, developed in the 1860s, allowed for better control over the chemical composition of steel, which improved its quality. Electric arc furnaces (EAF), introduced later, facilitated the melting of scrap steel using electric arcs, making it possible to recycle materials and produce high-grade steels, contributing to the industry's sustainability.

Why did British dominance in steelmaking decline?

British dominance in steelmaking declined due to competition from countries like Germany and the USA that invested in more efficient technologies. Britain was slow to adapt to new methods, like the open hearth process and basic oxygen steelmaking. Outdated facilities and economic pressures also contributed to the decrease in market share and industry influence.

What impact did the World Wars have on the steel industry?

The World Wars caused a surge in steel production due to the high demand for military hardware, vehicles, and infrastructure. This led to rapid industry expansion, technological advancements, and increased government support. Post-war, these advancements contributed to a more competitive global steel market with new challenges, such as overproduction and the need for modernization.

How is modern steelmaking addressing sustainability?

Modern steelmaking focuses on sustainability by improving recycling practices and eco-friendly production methods. Innovations like electric arc furnaces, which mainly use scrap steel, and the development of advanced high-strength steels (AHSS) aim to reduce environmental footprints. Continued investments in green technologies reflect the industry's commitment to ecological responsibility.