Table of Contents:

Introduction to Oxygen Steelmaking Process

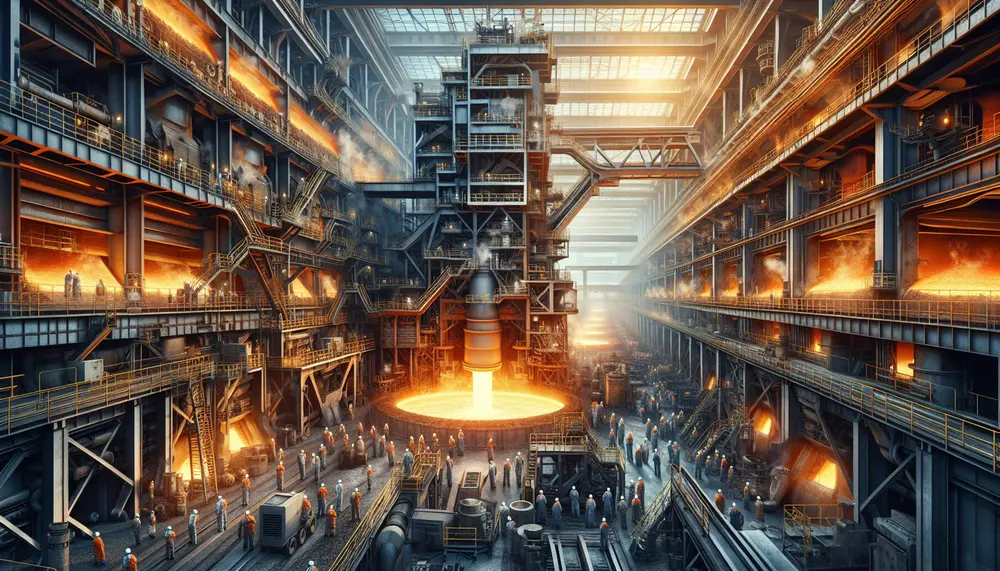

The oxygen steelmaking process is a cornerstone of modern steel production. It revolutionized the industry by introducing a more efficient and cost-effective method for producing high-quality steel. At its core, this process involves blowing pure oxygen into molten iron to reduce its carbon content and remove impurities. This results in a cleaner and more refined steel product.

Historically, steel production relied on methods like the open hearth furnace, which were slower and less efficient. The introduction of the Basic Oxygen Process (BOP) marked a significant shift. It not only accelerated production times but also reduced energy consumption and operational costs. Today, the oxygen steelmaking process accounts for over half of the world's steel production, underscoring its importance in the global steel industry.

Understanding this process is crucial for anyone involved in steel production or trade. It offers insights into how raw materials are transformed into one of the most versatile and widely used materials in the world. As we delve deeper into the specifics of the oxygen steelmaking process, you'll gain a comprehensive understanding of its components, benefits, and applications.

Key Components of the Basic-Oxygen Process

The Basic-Oxygen Process (BOP) relies on several key components that work together to transform molten iron into high-quality steel. Understanding these components is essential for grasping how the process functions efficiently.

Firstly, the converter is the central vessel where the oxygen steelmaking process occurs. It is a large, pear-shaped container made of robust materials to withstand extreme temperatures and chemical reactions. The converter is tilted to receive molten iron and then uprighted for the oxygen blowing phase.

Next, the oxygen lance plays a crucial role. This is a long, hollow tube that injects pure oxygen into the molten iron. The oxygen reacts with carbon and other impurities, facilitating their removal through oxidation.

Another vital component is the refractory lining inside the converter. This lining protects the converter's structure from the intense heat and corrosive nature of the molten materials. It is made from heat-resistant materials like magnesite or dolomite.

Finally, the slag formation is a critical aspect of the process. As impurities are oxidized, they form a layer of slag on top of the molten steel. This slag is periodically removed, ensuring the purity of the final steel product.

These components work in harmony to ensure the efficiency and effectiveness of the Basic-Oxygen Process, making it a preferred method in modern steel production.

Step-by-Step Guide to Oxygen Steelmaking

The oxygen steelmaking process is a precise sequence of steps that transforms raw iron into refined steel. Here’s a step-by-step guide to understanding how this process unfolds:

-

Charging the Converter: The process begins by tilting the converter and charging it with molten iron from a blast furnace. Scrap metal is often added to regulate the temperature and improve efficiency.

-

Blowing Oxygen: The converter is returned to an upright position, and the oxygen lance is lowered into it. Pure oxygen is blown at high pressure onto the molten iron, initiating a series of chemical reactions.

-

Oxidation of Impurities: The oxygen reacts with carbon and other impurities, forming gases like carbon monoxide and carbon dioxide. This oxidation process also generates heat, which helps maintain the molten state of the iron.

-

Formation of Slag: As impurities are oxidized, they combine with lime and other fluxes to form slag. This slag floats on the surface and is periodically removed to ensure the purity of the steel.

-

Sampling and Adjustments: Samples of the molten steel are taken to analyze its composition. Based on the results, adjustments are made by adding alloys or other materials to achieve the desired steel grade.

-

Tapping the Steel: Once the desired composition is achieved, the converter is tilted again to pour, or "tap," the molten steel into a ladle for further processing or casting.

This step-by-step guide highlights the precision and control involved in the oxygen steelmaking process, ensuring the production of high-quality steel.

The Role of Pure Oxygen in Steel Production

Pure oxygen plays a crucial role in the steel production process, particularly in the Basic-Oxygen Process. Its primary function is to facilitate the removal of impurities from molten iron, transforming it into high-quality steel.

Here’s how pure oxygen contributes to the process:

-

Oxidation of Carbon: When pure oxygen is blown into the molten iron, it reacts with carbon to form carbon monoxide (CO) and carbon dioxide (CO2). This reaction reduces the carbon content in the iron, which is essential for producing steel.

-

Heat Generation: The oxidation reactions are exothermic, meaning they release heat. This additional heat helps maintain the high temperatures required to keep the iron in a molten state, ensuring efficient processing.

-

Removal of Other Impurities: Oxygen also reacts with other impurities such as silicon, manganese, and phosphorus. These reactions form oxides that are absorbed by the slag, further purifying the steel.

-

Improved Efficiency: The use of pure oxygen accelerates the steelmaking process compared to older methods. It allows for quicker reactions and reduces the time needed to produce steel, leading to increased productivity.

In summary, pure oxygen is not just a component but a catalyst that drives the entire steelmaking process, ensuring the production of cleaner and more refined steel.

Benefits of the Oxygen Steelmaking Process

The oxygen steelmaking process offers numerous benefits that have made it the preferred method for steel production worldwide. These advantages contribute to its widespread adoption and continued relevance in the industry.

-

Increased Efficiency: The process is significantly faster than traditional methods, allowing for higher production rates. This efficiency translates to lower operational costs and increased output.

-

Improved Steel Quality: By effectively removing impurities, the process produces steel with superior mechanical properties and consistency. This high-quality steel is suitable for a wide range of applications.

-

Cost-Effectiveness: The reduced time and energy required for production lower overall costs. Additionally, the ability to use scrap metal as a raw material further decreases expenses.

-

Environmental Benefits: The process generates fewer emissions compared to older methods. The efficient use of resources and reduction in waste contribute to a smaller environmental footprint.

-

Flexibility: The oxygen steelmaking process can be adjusted to produce various steel grades, meeting diverse industry needs. This adaptability is crucial for catering to specific market demands.

These benefits underscore the importance and versatility of the oxygen steelmaking process, making it a cornerstone of modern steel production.

Common Challenges and Solutions in Steelmaking

While the oxygen steelmaking process is highly efficient, it is not without its challenges. Understanding these common issues and their solutions is key to optimizing production and maintaining high-quality standards.

-

Slag Control: Managing slag formation is crucial for maintaining steel purity. Excessive slag can lead to contamination. The solution involves precise control of the fluxes added and monitoring the slag's composition throughout the process.

-

Temperature Management: Maintaining the correct temperature is vital for efficient reactions. Temperature fluctuations can affect the quality of the steel. Implementing advanced monitoring systems and adjusting the scrap-to-iron ratio can help stabilize temperatures.

-

Oxygen Efficiency: Inefficient oxygen use can lead to incomplete reactions and increased costs. Ensuring the oxygen lance is correctly positioned and using optimal pressure settings can enhance oxygen efficiency.

-

Impurity Removal: Complete removal of impurities is challenging but essential. Regular sampling and analysis allow for timely adjustments in the process, ensuring impurities are effectively oxidized and removed.

-

Equipment Wear: The intense conditions within the converter can lead to wear and tear. Regular maintenance and using high-quality refractory materials can extend equipment life and reduce downtime.

By addressing these challenges with targeted solutions, steel producers can enhance the efficiency and quality of their operations, ensuring a reliable supply of high-grade steel.

Real-World Applications of Oxygen Steelmaking

The oxygen steelmaking process produces steel that is integral to numerous real-world applications. Its versatility and high quality make it suitable for a wide range of industries and uses.

-

Construction: Steel produced through this process is widely used in construction. It forms the backbone of skyscrapers, bridges, and residential buildings due to its strength and durability.

-

Automotive Industry: The automotive sector relies on high-quality steel for manufacturing vehicles. Steel's lightweight and robust properties contribute to fuel efficiency and safety.

-

Infrastructure: Railways, pipelines, and power plants utilize steel for its resilience and ability to withstand harsh conditions. The oxygen steelmaking process ensures the steel's reliability in these critical applications.

-

Appliances and Machinery: Household appliances and industrial machinery benefit from the precision and consistency of steel produced by this method. It ensures longevity and performance in everyday and industrial settings.

-

Energy Sector: Steel is essential in the energy sector, particularly in wind turbines and oil rigs. Its strength and adaptability make it ideal for withstanding environmental challenges.

These applications highlight the importance of the oxygen steelmaking process in producing steel that meets the diverse needs of modern society, supporting infrastructure, innovation, and growth across multiple sectors.

Conclusion and Future of Oxygen Steelmaking

In conclusion, the oxygen steelmaking process has established itself as a cornerstone of modern steel production. Its ability to efficiently produce high-quality steel has made it indispensable across various industries. The process's advantages, such as increased efficiency, cost-effectiveness, and environmental benefits, have cemented its role in the global steel industry.

Looking to the future, the oxygen steelmaking process is poised to evolve further. Innovations in technology and a growing emphasis on sustainability are driving the development of even more efficient and environmentally friendly methods. Potential advancements include:

-

Enhanced Automation: The integration of advanced automation and AI technologies could optimize the process, reducing human error and increasing precision.

-

Improved Energy Efficiency: Research into alternative energy sources and more efficient oxygen delivery systems could further reduce the process's carbon footprint.

-

Recycling and Waste Reduction: Developing methods to better incorporate recycled materials and minimize waste will be crucial for sustainable steel production.

As the steel industry continues to adapt to changing demands and environmental considerations, the oxygen steelmaking process will remain a vital component. Its ongoing evolution will ensure that it meets the challenges of the future, supporting infrastructure and innovation worldwide.

FAQ on Understanding the Oxygen Steelmaking Process

What is the Basic-Oxygen Process (BOP) and why is it important?

The Basic-Oxygen Process (BOP) is a method for steel production where pure oxygen is blown into molten iron to reduce carbon content and remove impurities. It is important because it produces high-quality steel efficiently and cost-effectively, making it crucial to global steel production.

How does pure oxygen contribute to steelmaking?

Pure oxygen reacts with carbon and other impurities in molten iron to form oxides. This reaction reduces the carbon content while generating heat to maintain high temperatures, aiding the production of cleaner, more refined steel.

What are the key components involved in the Basic-Oxygen Process?

Key components include the converter, oxygen lance, and refractory lining. The converter is where the process occurs, the oxygen lance injects oxygen, and the refractory lining protects the structure from intense heat and reactions.

What benefits does the oxygen steelmaking process offer?

This process is efficient, cost-effective, and produces high-quality steel with fewer impurities. It generates fewer emissions, can incorporate scrap metal, and is adaptable for producing various steel grades.

What challenges are faced in the oxygen steelmaking process and how are they resolved?

Challenges include managing slag formation, temperature control, and ensuring efficient oxygen use. Solutions involve precise control of fluxes, advanced monitoring systems, and maintaining equipment.