Posts on the Topic Steel production

Steelmaking nouns are essential for clear communication and safety in the steel industry, with evolving terminology requiring an up-to-date glossary. This article explains key terms like alloy, arc furnace, austenite, blast furnace, billet, basic oxygen process, carbon content, converter, casting,...

Converters are the core of modern steelmaking, rapidly transforming raw iron into high-quality steel through precise oxygen blowing and advanced process control. Their evolution—from Bessemer’s air-blown vessel to today’s digitally monitored systems—enables flexible, efficient production that meets diverse industrial demands....

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

Steel making induction furnaces revolutionize the industry by providing controlled, energy-efficient methods for melting and refining steel through electromagnetic induction. These furnaces offer key advantages such as precise temperature control, reduced emissions, faster melting times, versatility in metal types, and...

Understanding global steelmaking capacity is essential for industry stakeholders as it influences market dynamics, economic stability, and trade relations. Factors such as technological advancements, economic conditions, government policies, raw material availability, market demand, and global trade dynamics impact this capacity;...

The article explains the differences between steelmaking coal and thermal coal, highlighting their distinct uses in industry—steel production for steelmaking coal and electricity generation for thermal coal. It also discusses the importance of understanding these distinctions for businesses involved in...

The article explains the importance of understanding steelmaking coal prices, influenced by factors like supply and demand, environmental regulations, global trade, technological developments, alternative energy sources, and market speculation. It highlights how these elements impact price fluctuations and provides insights...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

The article discusses the significant environmental challenges of steelmaking, such as high CO2 emissions and energy consumption, and explores innovative solutions like the EPIXC Project's hydrogen-arc plasma technology. It also highlights the importance of recycling in reducing steel production's carbon...

Steel is indispensable in modern society due to its versatility and strength, playing crucial roles in construction, transportation, energy sectors, and everyday life. The steel-making process involves several complex steps from raw material preparation to rolling and finishing, while traditional...

Choosing the right steel making equipment manufacturer is crucial for ensuring efficiency, reliability, and safety in production processes. Key considerations include assessing experience and reputation, evaluating product range and quality, prioritizing technology and innovation, understanding customization capabilities, emphasizing customer support...

Steel making refractory materials are essential for lining furnaces and equipment in steel production, with various types like fireclay, high alumina, silica, magnesite, and chromite refractories tailored to specific conditions. These materials ensure heat containment, protect equipment from damage, maintain...

Steelmaking drawings are essential blueprints that ensure precision, coordination, cost control, time management, and quality assurance in steel production. Advanced tools like CAD and techniques such as FEA and BIM enhance the creation process by improving accuracy, efficiency, and collaboration...

Becoming a steel making operator involves overseeing the production of steel, ensuring quality and safety standards, and requires technical skills, attention to detail, problem-solving abilities, physical stamina, communication skills, and safety awareness. Educational requirements typically include a high school diploma...

Partnering with the largest steelmaking company offers numerous advantages, including a reliable supply chain, quality assurance, cost efficiency, access to innovation and technology, sustainable practices, global reach, and exceptional customer support. These benefits can significantly enhance your business operations by...

Green steelmaking aims to produce steel with minimal environmental impact by using innovative technologies and renewable energy sources, significantly reducing carbon emissions. Traditional methods rely heavily on fossil fuels and generate substantial CO2, whereas green alternatives like hydrogen-based reduction, electric...

Steelmaking refractories are crucial materials that withstand extreme conditions to facilitate steel production, enhancing the efficiency, safety, and cost-effectiveness of processes while ensuring product quality. They face challenges like high temperature fluctuations and corrosive environments but advancements in technology continue...

Graphite electrodes are essential in steel production, particularly for electric arc furnaces (EAF), where they conduct electricity to melt scrap metal at temperatures up to 3,000°C. Their effectiveness depends on properties like electrical conductivity and thermal shock resistance, influencing the...

Hydrogen steelmaking offers a sustainable alternative to traditional methods by using hydrogen as a reducing agent, significantly cutting carbon emissions and enhancing product quality. This method not only reduces the environmental impact but also supports integration with renewable energy sources,...

Steelmaking jobs encompass a wide range of roles beyond traditional production, including advanced areas like quality control and environmental compliance, requiring diverse professionals from metallurgists to engineers. The industry offers various career paths with competitive salaries and benefits, emphasizing innovation...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

The steelmaking industry is evolving with trends like sustainability, digital integration, and market adaptation, driven by cleaner technologies, AI and big data usage, and product diversification. Innovations such as Advanced High-Strength Steels (AHSS), electrolysis-based production processes reducing emissions, and 3D...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

Steelmaking waste, primarily consisting of slag, dust, and sludges from iron and steel production processes, poses significant environmental risks such as groundwater contamination and ecosystem degradation if not managed properly. However, innovative recycling techniques like using slag in concrete or...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

The Quintette Steelmaking Coal Mine in Tumbler Ridge, British Columbia, historically significant for its metallurgical coal crucial to steel production, has experienced fluctuations reflecting global market demands since opening in 1982. Currently mothballed with potential revival initiatives pending, the mine...

Nickel is essential in modern steelmaking, providing superior toughness, corrosion resistance, and non-magnetism that enable advanced applications across industries....

LRF steelmaking relies on precise temperature, chemistry control, and advanced digital technologies to ensure consistently high-quality, pure steel for demanding applications....

Vacuum Arc Remelting (VAR) is a secondary steel refining process using vacuum and controlled solidification to produce ultra-clean, homogeneous, high-performance steels....

In 2023, steelmaking faculty jobs increasingly favored candidates with interdisciplinary skills in advanced manufacturing and sustainability, emphasizing research funding ability....

This PDF guide offers a clear, up-to-date, and practical overview of steel making processes with visual aids, real-world examples, and industry statistics for students and professionals....

Global steelmaking varies by region, with Europe and Asia focusing on blast furnaces and efficiency or scale, while the Americas lead in sustainable electric arc furnace technology....

Steelmaking nouns are essential for clear communication and safety in the steel industry, with evolving terminology requiring an up-to-date glossary. This article explains key terms like alloy, arc furnace, austenite, blast furnace, billet, basic oxygen process, carbon content, converter, casting,...

Steelmaking videos captivate audiences by offering rare, visually stunning insights into complex industrial processes, blending spectacle with clear educational value....

Converters are the core of modern steelmaking, rapidly transforming raw iron into high-quality steel through precise oxygen blowing and advanced process control. Their evolution—from Bessemer’s air-blown vessel to today’s digitally monitored systems—enables flexible, efficient production that meets diverse industrial demands....

Kolkata’s steel industry is rapidly modernizing, offering diverse technical and managerial jobs driven by automation, sustainability, and digital transformation....

Steel manufacturing is vital for modern industry, with blast furnaces and electric arc furnaces as core methods; innovation drives efficiency, sustainability, and tailored properties....

Turkdogan’s Fundamentals of Steelmaking provides a deep, principle-based understanding that connects theory to practice, making it essential for anyone aiming to master or innovate in modern steel production....

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The global steel industry, vital for infrastructure and economic development, is evolving in 2023 through innovation, sustainability efforts, and fierce competition. Dominated by China with six of the top ten producers, the sector highlights strategic growth driven by technological advancements...

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...

Steelmaking is a transformative process involving precise temperature, timing, and techniques to turn iron into adaptable steel through methods like BF-BOF and EAF while addressing environmental challenges with innovations such as carbon capture and hydrogen-based processes....

India's steel industry, the world's second-largest producer, is crucial for economic growth and infrastructure development, driven by key players like Tata Steel and SAIL who enhance production capacity and exports through strategic locations....

The steel-making process transforms iron ore into steel, essential for modern life but environmentally challenging; innovations like electrification and AI aim to reduce emissions and improve sustainability....

The steel making business offers lucrative opportunities driven by rising demand in sectors like construction and automotive, requiring understanding of market dynamics, strategic planning, and significant investments in technology and infrastructure to succeed....

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

RH technology, initially developed for hydrogen removal in steel making, now plays a crucial role in secondary refining and purification to ensure high-quality steel production. Key advancements like oxygen lances, powder injection systems, the RH-TOP system, and modern vacuum pumps...

The article provides a comprehensive guide on steel making ore, detailing its types, extraction methods, and the importance of quality in producing high-grade steel. It emphasizes that understanding these aspects is crucial for improving efficiency and product quality in the...

The Ladle Metallurgy Furnace (LMF) is a crucial advancement in modern steel production, allowing for precise control over the chemical composition and temperature of molten steel to produce high-quality products. This technology involves transferring liquid steel into a specialized furnace...

Steel making induction furnaces revolutionize the industry by providing controlled, energy-efficient methods for melting and refining steel through electromagnetic induction. These furnaces offer key advantages such as precise temperature control, reduced emissions, faster melting times, versatility in metal types, and...

Steelmaking is a complex process that transforms raw materials like iron ore, coal, and limestone into high-quality steel through stages such as blast furnace melting, refining in Basic Oxygen or Electric Arc Furnaces, alloying, casting, forming, and finishing. Quality control...

Understanding global steelmaking capacity is essential for industry stakeholders as it influences market dynamics, economic stability, and trade relations. Factors such as technological advancements, economic conditions, government policies, raw material availability, market demand, and global trade dynamics impact this capacity;...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

The article explains the differences between steelmaking coal and thermal coal, highlighting their distinct uses in industry—steel production for steelmaking coal and electricity generation for thermal coal. It also discusses the importance of understanding these distinctions for businesses involved in...

VAD steelmaking, or Vacuum Arc Degassing, is a process that refines molten steel under vacuum to remove impurities and control chemical composition, essential for producing high-grade steel used in critical industries. The method involves steps like charging the ladle, vacuum...

The article explains the importance of understanding steelmaking coal prices, influenced by factors like supply and demand, environmental regulations, global trade, technological developments, alternative energy sources, and market speculation. It highlights how these elements impact price fluctuations and provides insights...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

The article discusses the significant environmental challenges of steelmaking, such as high CO2 emissions and energy consumption, and explores innovative solutions like the EPIXC Project's hydrogen-arc plasma technology. It also highlights the importance of recycling in reducing steel production's carbon...

The steel making LF process, involving a ladle furnace to refine molten steel, is essential for ensuring high-quality and specialized steel grades by controlling temperature and composition. Introduced in the 1960s, advancements in ladle furnaces have optimized this process, enhancing...

Steelmaking is a complex process involving several critical steps, from extracting iron to refining and shaping it into high-quality steel. Key stages include ironmaking, primary and secondary steelmaking, casting, forming, finishing, selecting appropriate materials like iron ore and coke, and...

The article explores the evolution of steel production in Europe, highlighting key innovations such as the blast furnace and Bessemer process, major production hubs like Germany and Italy, and the role of EUROFER in advocating for industry interests. It provides...

Steel is indispensable in modern society due to its versatility and strength, playing crucial roles in construction, transportation, energy sectors, and everyday life. The steel-making process involves several complex steps from raw material preparation to rolling and finishing, while traditional...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

Choosing the right steel making equipment manufacturer is crucial for ensuring efficiency, reliability, and safety in production processes. Key considerations include assessing experience and reputation, evaluating product range and quality, prioritizing technology and innovation, understanding customization capabilities, emphasizing customer support...

The article "Introduction to Ancient Steel Making" explores the historical context, key techniques, and materials used in ancient steel production across various civilizations. It highlights how early methods influenced modern steel making and underscores the ingenuity of our ancestors in...

Steel making techniques have evolved to become more efficient and environmentally friendly, with traditional methods like the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) being complemented by innovative technologies such as the Hydrogen Reduction Method. These advancements aim...

Steel making refractory materials are essential for lining furnaces and equipment in steel production, with various types like fireclay, high alumina, silica, magnesite, and chromite refractories tailored to specific conditions. These materials ensure heat containment, protect equipment from damage, maintain...

Steelmaking drawings are essential blueprints that ensure precision, coordination, cost control, time management, and quality assurance in steel production. Advanced tools like CAD and techniques such as FEA and BIM enhance the creation process by improving accuracy, efficiency, and collaboration...

Steelmaking generates significant wastewater containing contaminants like oil, metals, and acids. Effective management using various treatment methods is crucial for environmental protection, regulatory compliance, resource conservation, operational efficiency, and health safety....

Becoming a steel making operator involves overseeing the production of steel, ensuring quality and safety standards, and requires technical skills, attention to detail, problem-solving abilities, physical stamina, communication skills, and safety awareness. Educational requirements typically include a high school diploma...

Partnering with the largest steelmaking company offers numerous advantages, including a reliable supply chain, quality assurance, cost efficiency, access to innovation and technology, sustainable practices, global reach, and exceptional customer support. These benefits can significantly enhance your business operations by...

Japanese steelmaking blends ancient traditions with modern innovations, producing some of the world's finest steel. This article explores its rich history from early Tatara furnaces to advanced techniques today, highlighting the craftsmanship and enduring legacy of Japanese steel production....

Green steelmaking aims to produce steel with minimal environmental impact by using innovative technologies and renewable energy sources, significantly reducing carbon emissions. Traditional methods rely heavily on fossil fuels and generate substantial CO2, whereas green alternatives like hydrogen-based reduction, electric...

Steelmaking coal, also known as metallurgical or coking coal, is essential for producing coke used in blast furnaces to convert iron ore into steel. The article explores the types of steelmaking coal, its role in steel production, global demand dynamics,...

Steelmaking byproducts, such as slag, dust, and sludge, are valuable materials generated during steel production that can be repurposed in various industries to reduce waste and save costs. Utilizing these byproducts offers significant environmental benefits like waste reduction and lower...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

Kish, a carbonaceous byproduct primarily consisting of graphite and impurities like iron and slag, forms during the steelmaking process when molten iron cools. Effective removal of kish is crucial for producing high-quality steel with better mechanical properties, surface finish, product...

Steelmaking slag, a by-product of steel production, can be repurposed for various applications such as construction and cement production due to its valuable properties like strength, durability, and chemical stability. This not only reduces industrial waste but also promotes environmental...

Steelmaking and casting are interdependent processes essential for producing high-quality steel products. Steel is made using Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), then shaped through casting, which involves pouring molten steel into molds to create specific forms;...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

The article provides an in-depth look at the steelmaking process, covering its history from ancient methods to modern techniques like the Bessemer and Siemens-Martin processes. It details key stages such as raw material preparation, primary and secondary steelmaking, casting, shaping,...

Steelmaking refractories are crucial materials that withstand extreme conditions to facilitate steel production, enhancing the efficiency, safety, and cost-effectiveness of processes while ensuring product quality. They face challenges like high temperature fluctuations and corrosive environments but advancements in technology continue...

Steelmaking oxidation is a critical process in steel production, involving the intentional addition of oxygen to molten iron to trigger chemical reactions that remove impurities like carbon, silicon, and phosphorus, thereby enhancing the quality and properties of steel. This process...

Graphite electrodes are essential in steel production, particularly for electric arc furnaces (EAF), where they conduct electricity to melt scrap metal at temperatures up to 3,000°C. Their effectiveness depends on properties like electrical conductivity and thermal shock resistance, influencing the...

The article explains the essential materials and processes involved in steel production, highlighting iron ore, carbon (coke), limestone, manganese, aluminum, and zinc as key components. It details how these elements are processed through smelting and alloying to enhance properties like...

The article discusses the importance of understanding and optimizing key metrics in steelmaking yield, such as Gross Yield, Net Yield, and Yield Loss, to improve efficiency and sustainability. It also highlights factors influencing yield like raw material quality and technological...

Hydrogen steelmaking offers a sustainable alternative to traditional methods by using hydrogen as a reducing agent, significantly cutting carbon emissions and enhancing product quality. This method not only reduces the environmental impact but also supports integration with renewable energy sources,...

Vacuum degassing is a critical process in steel production that enhances the quality of steel by removing dissolved gases like hydrogen, oxygen, and nitrogen under vacuum conditions to prevent issues such as porosity and embrittlement. This method not only improves...

Stainless steel making is a complex process that begins with melting iron ore and other elements like chromium and nickel to create a durable, corrosion-resistant material. This involves several stages including refining, casting, and rolling, controlled by precise temperature and...

Steelmaking jobs encompass a wide range of roles beyond traditional production, including advanced areas like quality control and environmental compliance, requiring diverse professionals from metallurgists to engineers. The industry offers various career paths with competitive salaries and benefits, emphasizing innovation...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

The steelmaking tundish is a critical intermediary in the continuous casting process, serving as both a reservoir and buffer for molten steel while facilitating controlled flow and cleanliness to enhance final product quality. Its design has evolved since the 1950s,...

The steelmaking industry is evolving with trends like sustainability, digital integration, and market adaptation, driven by cleaner technologies, AI and big data usage, and product diversification. Innovations such as Advanced High-Strength Steels (AHSS), electrolysis-based production processes reducing emissions, and 3D...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

Steelmaking waste, primarily consisting of slag, dust, and sludges from iron and steel production processes, poses significant environmental risks such as groundwater contamination and ecosystem degradation if not managed properly. However, innovative recycling techniques like using slag in concrete or...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

Steelmaking transforms iron into steel by increasing carbon content and refining the material through methods like blast furnaces and adding additives. Modern techniques include Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), focusing on sustainability, with raw materials such...

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

The article emphasizes the critical importance of maintaining safe working conditions in the steelmaking industry, highlighting how safety measures not only protect workers from various health risks like respiratory issues and hearing loss but also enhance overall productivity and company...

Steel making technology has evolved from primitive forges to modern, efficient mills using methods like the Blast Furnace and Electric Arc Furnace (EAF), which recycles scrap metal. Recent innovations aim at enhancing efficiency and sustainability with developments such as advanced...

The Quintette Steelmaking Coal Mine in Tumbler Ridge, British Columbia, historically significant for its metallurgical coal crucial to steel production, has experienced fluctuations reflecting global market demands since opening in 1982. Currently mothballed with potential revival initiatives pending, the mine...

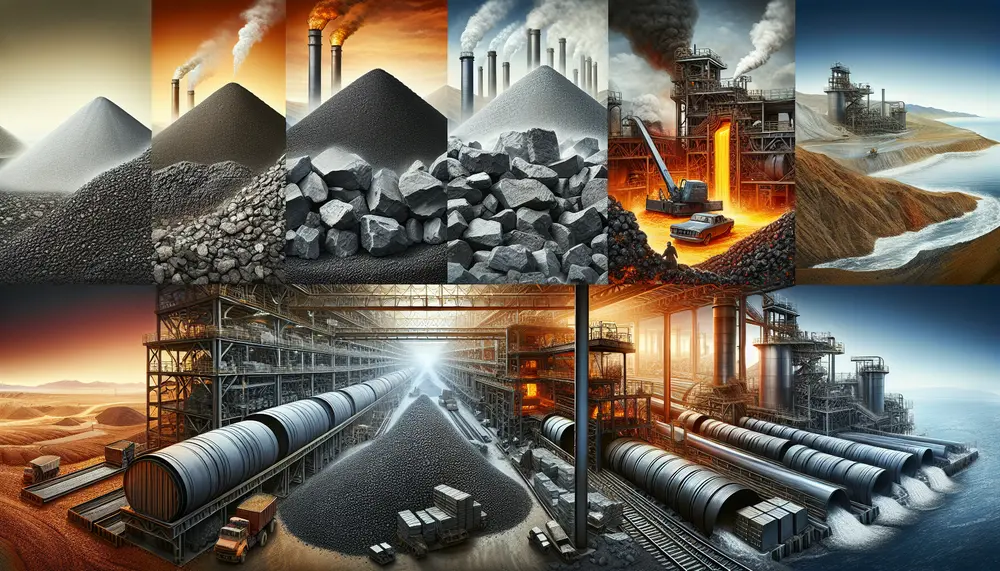

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

Top 10 posts in the category

Unsere Beiträge zum Thema Steel production

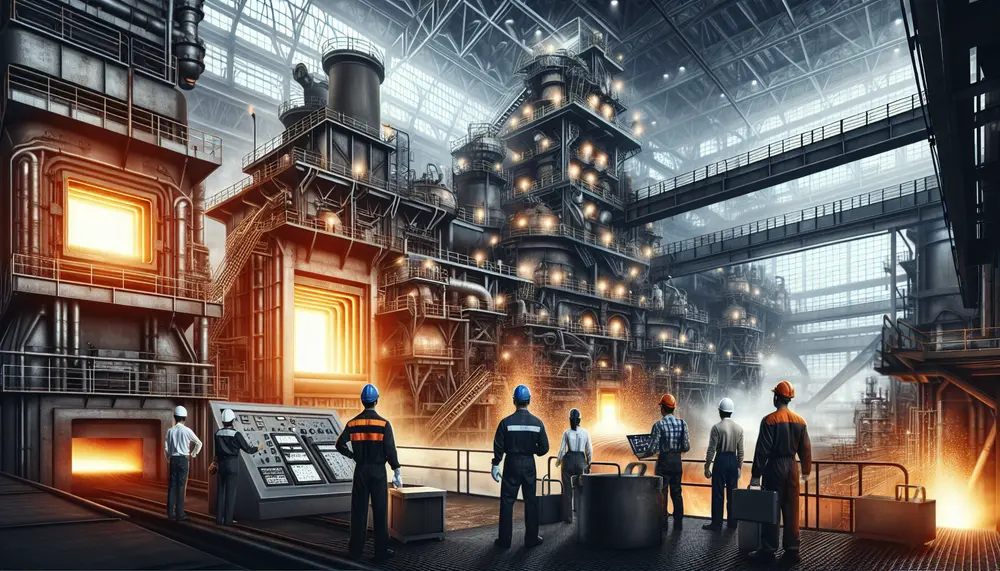

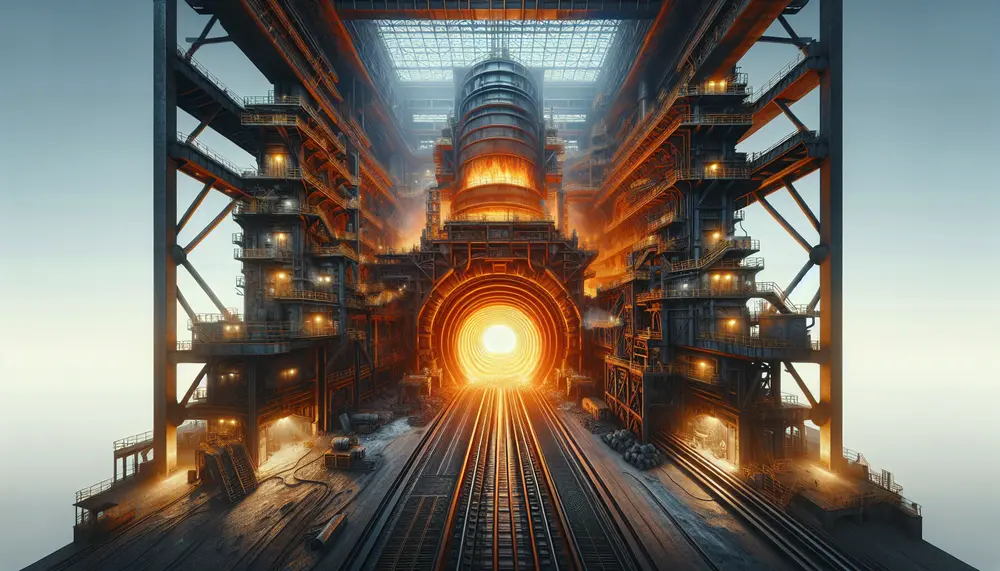

Steel production is the cornerstone of modern industry, a dynamic sector that continuously evolves with technological advancements, regulatory changes, and economic shifts. Understanding the intricacies of steel production is essential for professionals, stakeholders, and enthusiasts eager to stay ahead in this vital industry.

The category dedicated to steel production on our blog delivers in-depth analyses, cutting-edge trends, and comprehensive updates. Each article is crafted to enhance your knowledge base, providing actionable insights and a detailed exploration of the processes that transform raw materials into the steel that shapes our world. Our expertly curated content delves into every facet of the production process, from the extraction of iron ore to the smelting techniques that yield various steel grades.

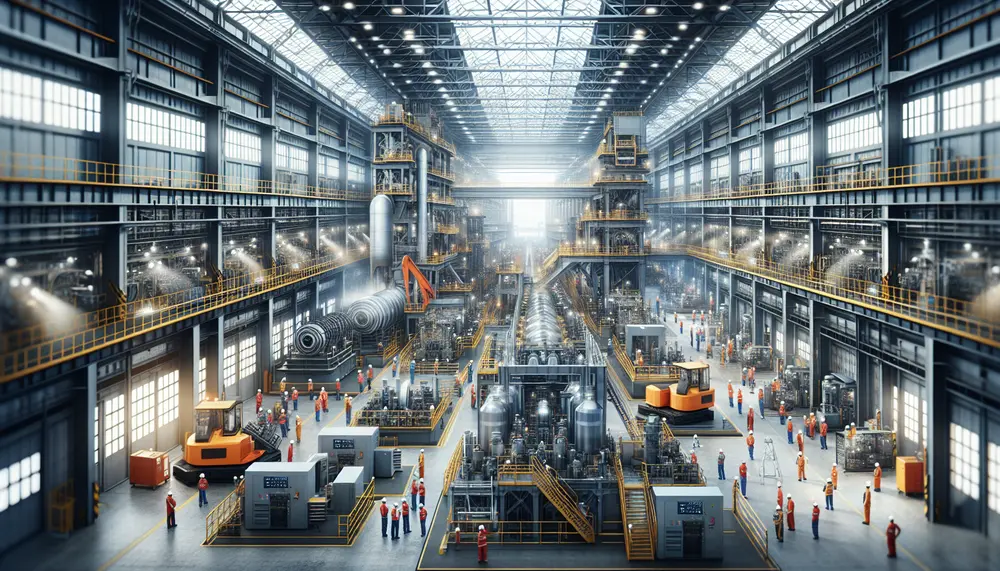

Readers who dive into our steel production category will find a valuable advantage in grasping the complexities of the industry. With our articles, you'll gain a refined understanding of operational efficiencies, explore the sustainability challenges and solutions within steel manufacturing, and learn about the latest innovations that drive the market. Whether you're involved in the steel trade, procurement, or you're simply fascinated by the journey from raw resource to finished product, these articles are tailored to broaden your perspective and enrich your professional acumen.

By reading through our well-researched and eloquently presented pieces, you'll empower yourself with a wide-ranging command of steel production that can influence decision-making, investment strategies, and even day-to-day conversations about this pivotal industry. Join us as we unravel the complexities of steel production, providing you with the knowledge to excel in your field and harness the potential of one of the world's most indispensable materials.