Table of Contents:

The Versatility of Steel in Modern Industry

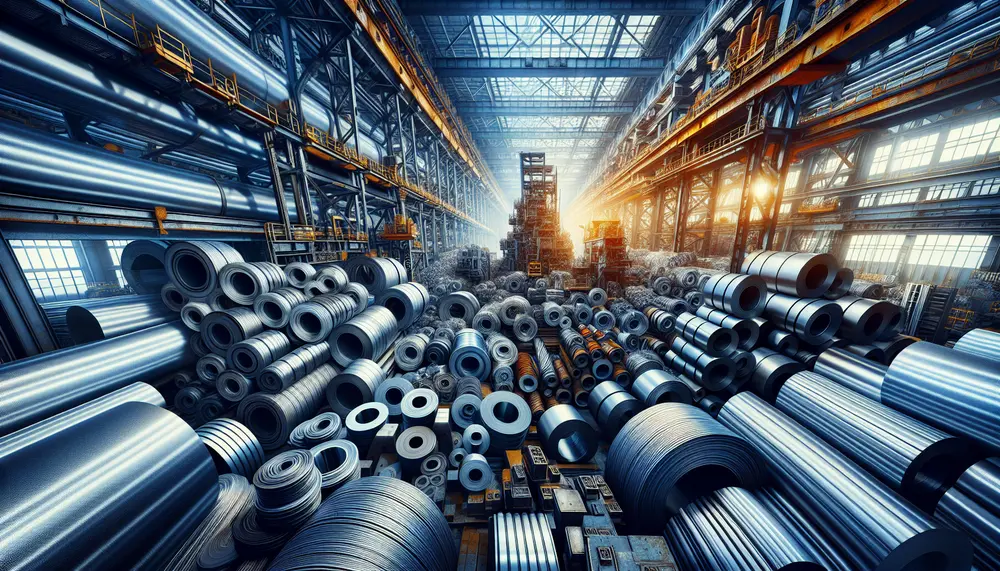

When we speak of industrial innovation and efficiency, products made out of steel often lie at the heart of such conversations. The reason for this is clear – steel possesses a quality of versatility that few other materials can match. Its impressive strength-to-weight ratio makes it an indispensable resource for various sectors that form the backbone of modern industry.

This incredible material can be tailored to meet specific needs, with hundreds of steel grades available, each designed for a particular use. From the high-tensile varieties used in skyscrapers to the stainless grades essential in food processing and medical equipment, steel's adaptability is second to none.

Apart from its well-known applications in major structures and vehicles, steel's use branches out into many other industrial products. For example, specialized steel alloys are critical components in the manufacturing of tools, machinery, and even the smallest of hardware, ensuring durability and precision.

Moreover, products made out of steel lead the way in technological advancement, forming the framework for electrical and digital systems that keep us connected. The conductivity and protective qualities of certain steel products facilitate the production of secure, efficient electronic devices, power infrastructures, and innovative computing technologies.

| Industry Sector | Steel Product Example |

|---|---|

| Construction | Reinforcement bars |

| Automotive | Vehicle frames |

| Technology | Computer casings |

| Energy | Wind turbine towers |

| Consumer Goods | Household appliances |

The vast range of products made out of steel tells a story of a material deeply integrated into every facet of industrial progress. It's a narrative of continued growth, resilience, and innovation – a testament to steel's irreplaceable role in paving the way for a future that's stronger, safer, and more sustainable.

Key Advantages of Steel Products

Steel offers a unique portfolio of benefits making it a superior choice for a multitude of applications. The key advantages of steel products stem from their intrinsic properties such as unmatched durability and resistance to wear and tear. This longevity means that steel structures and products rarely need replacement, providing long-term value and reducing the need for frequent refurbishment.

Another critical advantage is steel's remarkable ability to withstand extreme conditions. It can endure high temperatures, pressure, and corrosive environments, which makes it perfect for use in harsh industrial settings. This reliability extends to its performance in natural disasters, like earthquakes and hurricanes, where steel's strength can mean the difference between life and death.

- Corrosion Resistance: Certain grades of steel are designed to resist rust and chemical breakdown, ensuring lifespan and aesthetics are maintained.

- Flexibility and Adaptability: The ductility of steel allows it to be molded into almost any shape without compromising its integrity, paving the way for innovative design and architecture.

- Magnetic Properties: Being naturally magnetic, steel is essential in the manufacture of electronics and electrical systems.

From a practical standpoint, steel is also favored for its maintenance ease. Its surfaces can be easily cleaned to meet the strict hygiene standards required in food production, medical facilities, and other sterile environments. Additionally, steel's capacity for recycling not only adds to its economical value but also exemplifies its role in building a sustainable future.

“Steel’s resilience and efficiency underpin its reputation as the cornerstone of modern industry – it is not just a material, but a modern marvel that continues to push the boundaries of innovation.”

Finally, the safety aspect of products made out of steel cannot be overstated. Its fire-resistant qualities and the predictability of its behavior under load make it a safe choice for both manufacturing processes and end-use products. With steel, industries can meet rigorous safety standards and protect human lives.

Innovative Uses for Steel in Everyday Life

Steel's remarkable attributes have not just revolutionized industrial sectors but have also enhanced our everyday life in surprising ways. The material's versatility opens up a world of innovative uses, making our day-to-day experiences more convenient, efficient, and safe.

Consider the realm of modern home appliances, for instance. Steel is at the core of high-performance cookware, offering excellent heat conduction and resistance to deformation under high temperatures. Imagine the sleekness of stainless steel fridges and ovens that not only perform reliably but also contribute to the contemporary aesthetic of our kitchens.

- Smartphone Frames: Providing durability and elegance, steel is frequently employed in the frames and cases of smartphones.

- Watches and Wearables: The precise engineering of wristwatches and the growing market of smart wearables often rely on steel's luxury feel and robustness.

- Exercise Equipment: From weights to machines, steel empowers our fitness routines, combining safety with longevity.

In the sphere of entertainment and leisure, the acoustic properties of steel find a place in musical instruments such as guitars and pianos, where strings and structural components made from steel contribute to crystal-clear tones. Even in art installations and sculptures, artists often opt for steel to express their creative visions, knowing it will withstand the test of time.

Heading outdoors, steel becomes the invisible hero in gardening tools, outdoor furniture, and even in the durable construction of bicycles. As a boon for eco-conscious consumers, many of these items can be made from recycled steel, closing the loop and minimizing environmental impact.

“Steel slips into our lives, often unnoticed, quietly but assuredly advancing our pursuit of functionality and form.”

One cannot overlook the myriad of gadgets and devices that incorporate products made out of steel for their seamless operation. Whether part of the intricate machinery inside a camera lens or forming the sleek exterior of a USB flash drive, steel continues to support and propel our highly connected, technology-driven lifestyles.

Steel in Construction: Building a Stronger Future

The foundation of modern architecture and construction is inextricably linked with the use of steel. Its application in the construction sector has reshaped city skylines and infrastructure, thereby sculpting the world we live in today. Steel in construction offers a blend of resilience and flexibility, allowing architects and engineers to push the boundaries of innovation and design.

One of the most significant contributions of steel to the construction industry is the steel-framed building. These structures capitalize on the material's strength and ductility, enabling the construction of taller, more expansive buildings that can withstand the pressures of natural forces. Moreover, steel's prefabrication advantages facilitate faster construction times, reducing labor costs and allowing for more precise assembly.

- Modular Construction: Steel’s modularity streamlines the building process, enabling pre-assembled components to be quickly installed on-site.

- Infrastructure Development: Bridges, tunnels, and railroads benefit from steel's tenacity, enduring the rigors of daily use and natural elements.

- Eco-friendly Buildings: With the growing emphasis on green construction, steel's recyclability makes it a staple in eco-conscious building projects.

Furthermore, the adaptability of steel is highlighted in its use in retrofitting older buildings. Strengthening and expanding existing structures is often more sustainable and cost-effective than new construction, and steel products play a pivotal role in such modernization efforts.

As we envision a dynamic future, the integration of products made out of steel in smart building technologies is on the rise. These state-of-the-art systems utilize steel's conductive properties to enhance building management, energy efficiency, and sustainability efforts. It is clear that steel is not only building our present but is also a key ingredient in constructing a stronger, more innovative future.

“Steel's contribution to the construction industry is monumental, building frameworks that are not only physically imposing but also symbolize progress and human achievement.”

Transportation and Automotive: The Role of Steel

The transportation and automotive industries have long relied on steel to provide the safety, durability, and strength needed for vehicles of all types. The role of steel in these industries is crucial, enhancing not only the performance and longevity of vehicles but also their economic and ecological efficiency.

Advanced high-strength steels (AHSS) are at the forefront of automotive innovation, allowing for lighter yet stronger vehicles that offer improved fuel efficiency and reduced emissions. This aligns with the global push towards more sustainable modes of transport and the automotive industry's focus on reducing its carbon footprint.

- Vehicle Safety: Steel's robustness is integral in the design of crumple zones and safety cages, absorbing impact and protecting passengers during collisions.

- Mass Transportation: Trains, buses, and ships utilize steel to create frameworks that can carry heavy loads over long distances reliably and safely.

- Aerospace Industry: The aerospace sector benefits from specialty steel alloys that can endure the extreme conditions of flight and space exploration.

In addition to its structural applications, steel plays a vital role in the precision-crafted components found in the engines and transmissions of vehicles. These components must withstand high stress and temperatures, making the thermal resistance and resilience of steel invaluable.

Moving beyond traditional applications, steel is also a key player in the emergence of electric vehicles (EVs). As the automotive industry shifts toward electric power, steel is helping to pave the way, with specially designed steel grades that optimize the performance of EV batteries and motors.

"Steel's legacy in the transportation sector is marked not just by its historical use, but by its adaptability and ongoing evolution to meet the needs of a fast-moving world."

Whether it's in the cars we drive, the trains we ride, or the planes we fly, products made out of steel are intrinsic to the way we move and connect. As the transportation and automotive industries continue to innovate, steel will undoubtedly remain a key material, driving us forward into a future with ever-increasing demands for efficiency and sustainability.

Medical Applications: The Steel Difference

The medical field is an arena where precision, hygiene, and reliability are non-negotiable. Steel, known for its immaculate composition, lends itself to a range of applications that meet the stringent standards of healthcare environments. The steel difference is evident in its widespread use in medical applications, where it contributes to life-saving innovations and everyday healthcare practices.

Stainless steel, in particular, is prized for its corrosion resistance and ease of sterilization, making it ideal for surgical instruments, implants, and hospital equipment. The antibacterial properties of stainless steel also inhibit the growth of harmful pathogens, ensuring patient and practitioner safety.

- Surgical Tools: Scalpels, scissors, and forceps made from stainless steel are valued for their precision and durability.

- Orthopedic Implants: Steel is used to manufacture pins, plates, and rods that facilitate bone repair and are biocompatible.

- Medical Devices: From MRI machines to heart monitors, steel enclosures protect sensitive medical technology from interference and damage.

Advancements in steel technology have resulted in development in the area of custom medical prosthetics. Utilizing robust yet flexible steel alloys, these prosthetics offer amputees the strength and versatility needed for an active lifestyle. Beyond prosthetics, dental braces and various orthodontic devices demonstrate another facet of steel's impact on personal health.

"In the precision-demanding realm of medicine, the choice of material is critical, and steel stands out as a trusted ally in the relentless pursuit of human well-being."

In diagnostic applications, steel's radiopacity is a significant advantage allowing for clear imaging results. Additionally, the fact that steel can be crafted into ultra-thin wires and tubes facilitates the production of catheters and other minimally invasive tools that are transforming modern surgery.

With its unparalleled combination of strength, sterility, compatibility, and minimal maintenance requirements, products made out of steel are integral to the medical industry. It's clear that as medical science advances, steel will continue to be a cornerstone in the creation of devices and tools that not only save lives but also improve the quality of life.

Sustainability and Recycling: Steel's Environmental Edge

In today's eco-conscious world, the sustainability and recyclability of materials are of paramount importance. Steel boasts an exceptional environmental edge due to its unique ability to be recycled indefinitely without loss of quality. The magnetism of steel also aids in its efficient recovery from waste streams, further enhancing its recycling efficiency.

Recycled steel reduces the industry's carbon footprint and conserves natural resources by minimizing the need for new raw material extraction. This conservation is crucial in mitigating the environmental impact of construction and manufacturing processes.

- Energy Conservation: The energy saved by recycling steel is substantial, contributing to a reduction in overall industrial energy consumption.

- Emission Reduction: Through recycling and the use of electric arc furnaces, modern steel production has significantly lowered greenhouse gas emissions.

- Resource Preservation: Reusing steel preserves iron ore, coal, and limestone, reducing the environmental strain from mining and quarrying activities.

The industry’s commitment to circular economy principles exemplifies the proactive steps being taken to ensure steel remains a foundational yet sustainable material. New technologies and processes are continually being developed to make the production and recycling of steel even more energy-efficient and environmentally friendly.

"Steel's capacity to be recycled perpetually underscores its vital role in building a more sustainable future, aligning longevity with environmental stewardship."

Moreover, the robustness and longevity of products made out of steel mean that they often outlast their counterparts made from other materials, leading to less waste and a lower demand for replacement products. This contributes further to the reduction of environmental impacts throughout the product life cycle.

As we look to a future where sustainable practices are no longer optional but imperative, steel stands as a shining example of an industry that is not only adapting but leading the way in environmental responsibility. The next time we encounter products made out of steel, we can appreciate not just their functionality or aesthetic appeal, but also their part in a larger, greener narrative.

Steel in Art and Design: A Creative Medium

Steel is not only a foundational building block for industrial applications; it is also a medium that captivates artists and designers around the world. Steel in art and design transcends traditional boundaries, offering a blend of durability and malleability that ignites creative expression.

Designers prize steel for its sleek and modern aesthetic, its ability to be crafted into both sturdy and delicate forms, and its compatibility with other materials. In architecture, steel enables the creation of structures with expansive open spaces, thanks to its tensile strength, while in interior design, it provides a contemporary edge in furniture and decor.

- Cultural Monuments: Iconic landmarks and sculptures that withstand the test of time owe their resilience to steel's robust nature.

- Functional Art: Everyday objects, from lighting fixtures to jewelry, are elevated to art pieces through the innovative use of steel.

- Public Installations: Steel’s capacity for large-scale works makes it a common choice for public art that engages communities in shared spaces.

In the hands of sculptors, steel becomes a transformative substance that can be shaped, welded, and even colored, achieving textures and forms limited only by imagination. Steel's ability to withstand outdoor elements also makes it a favored choice for public art and garden sculptures.

"The elegance and versatility of steel continue to inspire artists and designers, proving that this industrial material can also master the art of beauty and impact."

Further illustrating steel's creative usage, fashion designers integrate steel mesh and plating into avant-garde clothing and accessories, fearlessly experimenting with its industrial charm to make bold statements.

Steel's role in art and design reflects its multifaceted character. As much as it is the backbone of functional construction, it is also the canvas for innovation, allowing creators to challenge the norms and bring a new perspective to the synthesis of form and function. Ultimately, products made out of steel in the artistic realm enrich our culture, demonstrating that this material's applications are as boundless as our creativity.

The Future of Steel: Trends and Innovations

The burgeoning advancements in the steel industry forecast an intriguing future, laden with trends and innovations that will further reframe its significance across all sectors. The future of steel is tightly interwoven with technological progress, addressing both the demand for novel applications and the ever-growing need for sustainability.

One of the central trends in the industry is the development of smarter steel-making technologies. These are set to reduce environmental impact through energy reduction and process optimization, signifying a move toward greener and more efficient production methods.

- Lightweight Steel Alloys: Ongoing research into material science is producing lighter, stronger steel grades that maintain performance while enhancing energy efficiency.

- 3D Printing with Steel: Additive manufacturing, or 3D printing, is opening up new possibilities for steel in complex, customized shapes and structures.

- Coated Steels: New coatings are being developed that imbue steel with additional properties, such as self-healing or self-cleaning surfaces, expanding its practical applications.

As we step into a world where adaptability is key, steel is expected to play a pivotal role in the infrastructure needed for renewable energy systems. Wind turbines, solar panel frames, and hydrogen cells rely on the fortitude of steel products to ensure persistent energy delivery.

Alongside its role in energy, steel’s contribution to the digital landscape is evolving. With burgeoning fields such as robotics and artificial intelligence, steel will continue to be an integral material for constructing the hardware that will drive further automation and connectivity.

"Revolutionary in its essence, steel's journey weaves through past industrial feats and heralds a continued legacy of ingenuity and invention."

The trajectory steel is on emphasizes not just its current value, but how it will shape, support, and propel future trends and innovations. Steel's inherent adaptability means it will continue to contribute to cutting-edge developments, echoing its timeless relevance in a rapidly changing world. Beyond any doubt, products made out of steel will remain central to our progress, embodying the fusion of strength, innovation, and sustainability.

Understanding Steel Grades and Their Impact on Products

Every steel product begins its life with a specific recipe – a combination of elements and processing that gives it unique properties. Understanding steel grades is critical for selecting the right material for a given application, as each grade impacts the performance, durability, and sustainability of the products made from it.

Steel grades are classified based on their chemical composition and the processes through which they are manufactured. These classifications determine the mechanical properties of the steel, such as its strength, ductility, and malleability, which in turn dictate its suitability for various applications.

- Carbon Steel: The carbon content in these steels influences hardness and strength, suitable for construction and machinery.

- Alloy Steel: Alloying elements like chromium, nickel, and molybdenum enhance specific properties, including corrosion resistance and toughness.

- Stainless Steel: Known for its corrosion resistance, this steel is ideal for medical tools, kitchenware, and architecture.

- Tool Steel: High carbon and alloy content make this steel perfect for cutting and drilling equipment.

The impact of steel grades on products is profound. For example, high-strength, low-alloy steels are often used in automotive applications to reduce weight without sacrificing safety. On the other hand, the surgical instruments' industry relies on particular stainless steel grades that can be easily sterilized and offer exceptional durability.

"Choosing a steel grade is not merely a technical decision but a choice that shapes a product's lifecycle, environmental impact, and role in a sustainable economy."

In essence, the grade of steel chosen for any product is a foundational decision, one that determines not just how that product will be used, but also how long it will last and how it can be recycled at the end of its life. As consumers and industries alike become more aware of and responsible for their ecological footprint, the importance of selecting the appropriate steel grade cannot be overstated.

How to Choose the Right Steel Products for Your Project

Selecting the optimal steel products for a particular project is a nuanced process that requires careful consideration. To ensure the success of a project, one must understand the specific needs and challenges that the project presents. The right steel products can significantly influence the efficiency, cost, and overall outcome of a project.

Begin by examining the environmental conditions to which the steel will be exposed. Will it face extreme temperatures, corrosive substances, or heavy wear and tear? The answers to these questions will guide you towards a steel grade with the appropriate resistance and durability.

- Determine the Project Requirements: Evaluate the mechanical and chemical stresses that the steel will need to withstand.

- Consider the Required Strength and Weight: Projects like high-rise buildings or bridges demand steel with high tensile strength, while others may prioritize lightweight steel for ease of transportation and assembly.

- Assess the Budget: Balance cost with performance, opting for steel grades that meet project specifications without unnecessary expenditures.

- Review Regulatory Standards: Ensure that the steel products comply with local and international building codes and safety regulations.

Consultation with a steel specialist can also provide insights into the availability of materials and potential alternatives that may offer additional benefits or cost savings. Suppliers with comprehensive inventories and knowledgeable staff can help identify the most suitable products quickly and accurately.

"The harmony between a project's vision and the steel products used is a symphony of careful planning, material expertise, and strategic selection."

In conclusion, choosing the right steel products involves a deep understanding of project objectives, an evaluation of environmental and structural demands, a balancing of cost and functionality, and adhering to regulations. With these considerations in place, you can select steel products that will not only meet but exceed expectations, securing both the project's integrity and its future performance.

Maintaining and Caring for Steel Products

The longevity and performance of steel products are not only determined by their initial quality but also by how well they are maintained. Proper care and maintenance can significantly extend the useful life of steel structures and items, ensuring they continue to function effectively and look aesthetically pleasing.

Regular cleaning is essential, particularly for stainless steel products that are used in environments susceptible to contamination, like kitchens or hospitals. Simple washing with soap and water, followed by a thorough rinse and dry, usually suffices to maintain the material's luster and prevent the buildup of harmful residues.

- Inspect Regularly: Systematic checks can help identify issues such as corrosion or wear early, enabling timely intervention.

- Protective Coatings: Applying or reapplying protective paints or coatings can shield steel from environmental factors that may cause deterioration.

- Proper Storage: Ensure steel products are stored in a dry place and are adequately covered to protect them from moisture and dust.

- Avoid Harsh Chemicals: Use suitable cleaning agents designed for steel, and avoid chlorine-based or abrasive cleaners that can damage the surface.

In outdoor settings or industrial environments, preventative measures might include the application of corrosion inhibitors or regular oiling, depending on the nature of the steel product and its exposure to the elements.

"Taking the time to maintain steel products is a testament to their importance in our daily lives, representing an investment in both the present and the future."

It is also imperative that any repairs to steel structures or products are carried out with the appropriate techniques and materials, ensuring compatibility and preserving the integrity of the original design. This includes matching steel grades for welded repairs or using the correct fasteners for mechanical joints.

In summary, caring for steel products is an ongoing commitment that rewards with durability and sustained performance. By adhering to a routine of cleaning, protection, and careful use, you ensure that steel continues to play its vital role across various applications undiminished by the passage of time.

Steel Production: A Glimpse Behind the Scenes

The production of steel is a complex and fascinating process, blending both ancient methods and innovative technology. A glimpse behind the scenes of steel production reveals the intricate steps and meticulous care taken to transform raw materials into the versatile steel products that are fundamental to our world.

The journey begins with the extraction of iron ore, the primary raw material used to make steel. After mining, the ore is crushed and then purified through the smelting process, where high temperatures are used to separate the iron from other minerals. The resultant molten iron, also known as hot metal, is the primary substance used to produce steel.

- Blast Furnace: A traditional yet powerful method where iron ore is reduced to iron using coke and limestone under high heat.

- Basic Oxygen Furnace (BOF): Here, molten iron from the blast furnace is transformed into steel by blowing oxygen to reduce carbon content and adjust the composition.

- Electric Arc Furnace (EAF): Predominantly used for recycling scrap steel, this method utilizes electric arcs to melt the materials, making it a more energy-efficient option.

Following the initial melting and refining processes, steel is cast into various shapes – billets, blooms, or slabs. This semi-finished steel is then subject to further processing like hot rolling, which shapes it into usable forms such as rods, beams, or sheets.

"The alchemy of steel production is a mix of raw elemental power and precise scientific control, a testament to human ingenuity and its enduring quest to master materials."

Quality control is a crucial stage in steel manufacturing, with each batch rigorously tested for strength, flexibility, and chemical composition to ensure it meets the required standards. Once certified, the steel is ready for distribution and use in countless applications, from infrastructure to delicate instruments.

In essence, steel production is about transformation – the turning of the earth's resources into a material that defines modern civilization. The seamless melding of high-heat furnaces, powerful machinery, and precise chemical engineering marks steel production as one of humanity’s most impressive manufacturing feats.

The Economic Impact of the Steel Industry

The steel industry is a powerhouse of economic activity, fueling growth and development on a global scale. Its impact stretches far beyond the mills and foundries where steel is produced, influencing entire sectors and contributing significantly to national economies.

As a key material in construction, transportation, and manufacturing, steel's demand is often seen as an indicator of economic health. The industry's reach is vast, with countless jobs directly linked to steel production, distribution, and processing.

- Job Creation: From miners to metallurgists, the steel industry employs millions worldwide, driving employment and economic stability.

- Infrastructure Development: Investments in large-scale projects like bridges, railways, and stadiums depend on steel, stimulating further economic activity.

- International Trade: Steel is one of the most traded commodities globally, with a complex supply chain that spans continents and borders.

Moreover, the industry's push towards sustainability is fostering innovation and prompting investment in new technologies. This progress has the potential to create new markets and opportunities, driving economic diversification and resilience.

"The steel industry’s ripple effect on the economy is profound, creating pathways for trade and innovation that fuel the fires of progress."

As a foundation for emerging industries such as renewable energy, the steel industry's role in the economy is both foundational and forward-looking. By enabling the construction of wind turbines, solar farms, and electric vehicle infrastructure, steel is at the forefront of the green economy, marrying economic growth with ecological consciousness.

In conclusion, the economic impact of the steel industry is multi-dimensional, reaching far into the societal fabric. By providing employment, enabling infrastructure, and facilitating trade, steel remains an invaluable contributor to our livelihoods and an agent of economic vitality.

Steel Safety Standards and Certifications Explained

Steel safety standards and certifications are pivotal in ensuring that products made out of steel meet the rigors of their intended use, especially when it comes to public and occupational safety. These benchmarks are set by recognized bodies to govern the quality, performance, and safety characteristics of steel products.

Safety standards often prescribe the physical and chemical properties that steel must possess for specific applications. This includes detailing the minimum requirements for tensile strength, yield strength, impact resistance, and elongation, amongst other parameters.

- ASTM International: Provides a wide range of voluntary consensus standards for steel products and services used globally.

- ISO (International Organization for Standardization): Offers international standards that ensure the quality, efficiency, and safety of products and services, including those related to steel.

- EN (European Norm): Consolidates various regional standards within Europe into a unified system, applying to steel production and usage within the EU.

Certifications are granted when steel products have been independently verified to adhere to the relevant safety standards. These certificates are a guarantee that the steel has undergone stringent testing and quality control measures. They reassure consumers and industry professionals that the steel they are using is up to code and can perform safely under the expected service conditions.

"Navigating the landscape of steel safety standards and certifications is essential, as these guidelines are the backbone of industrial integrity and public safety."

Manufacturers and fabricators often undergo regular audits to maintain their certification status, ensuring continuous compliance and quality. By doing so, they not only fulfill legal requirements but also contribute to building trust with clients and end-users who rely on the safety of their steel products.

Ultimately, these safety standards and certifications form a crucial part of the steel industry's commitment to upholding the highest levels of quality and reliability, safeguarding both lives and property in countless applications.

Frequently Asked Questions: The Dynamic World of Steel Products

What makes steel a critical component in modern industries?

Steel's versatility, high strength-to-weight ratio, and adaptability make it indispensable across various industries. It's ideal for construction, automotive, technology, and many other applications due to its durability and flexibility.

How are steel products beneficial for sustainable development?

Steel is highly recyclable, which conserves resources and energy. It can be recycled indefinitely without losing quality, thereby reducing its environmental footprint and playing a significant role in sustainable development initiatives.

What are some innovative uses for steel in everyday life?

Beyond industrial uses, steel is found in smartphones, wearables, home appliances, exercise equipment, musical instruments, and even in art and design, offering a combination of durability and aesthetics.

Why is steel considered a safe material in construction and manufacturing?

Steel's fire resistance, predictability under load, and robustness make it a safe material. It's widely used in construction for its ability to endure natural disasters and enable strong safety cages in vehicles.

Can steel adapt to the evolving demands of technology?

Yes, steel continues to adapt to technological progress with developments in material science and innovative applications. It's essential in the manufacturing of electronics and is pivotal in the infrastructure of renewable energy systems.