Table of Contents:

Understanding Steel Production Technology: A Primer

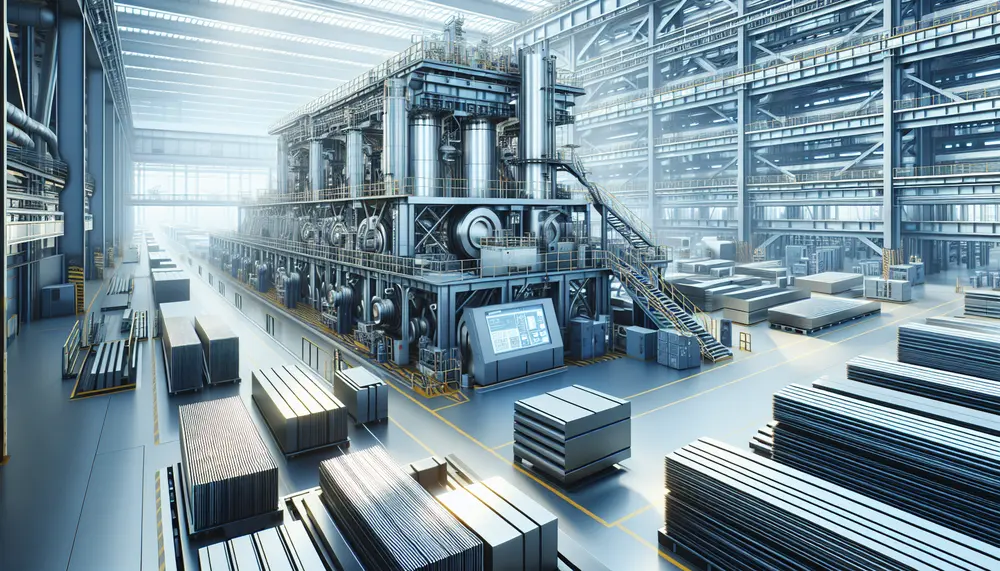

Steel production is a cornerstone of modern industry, and it has come a long way from its early days. From towering blast furnaces to the advanced electric arc furnaces, the journey of steel making is rich with technology and innovation. To fully grasp the current landscape and what the future holds for steel production technology, it's vital to have a foundational understanding of the processes involved.

At its core, steel production involves the transformation of raw materials, like iron ore, into high-strength, durable steel. This is accomplished through a series of steps, each leveraging cutting-edge technology to optimize the process. But what exactly goes on inside these large industrial complexes? How has technology elevated traditional methods to meet the needs of an evolving global market?

Two main processes dominate the industry: the traditional blast furnace method, which relies on coke to extract iron from ore, and the more modern electric arc furnace technique, which recycles scrap steel using high-power electric arcs. Both methods employ a myriad of technologies to refine raw inputs into the steel that meets the stringent demands of today’s users.

Technological advancements have not only improved the quality and precision of steel products but have also prioritized environmental sustainability. For instance, natural gas is increasingly being used as a cleaner alternative to coke in blast furnaces, helping to reduce the industry's carbon footprint. Additionally, the industry now employs advanced sensors and control systems that allow for real-time adjustments and greater efficiency during production.

Steel is more than just an industrial product; it's the backbone of infrastructure, the framework of skyscrapers, and an essential component in automobiles. With the future pointing towards even more sustainable, efficient, and smarter steel production new technology, understanding the basics is the first step in appreciating the full scope of this crucial field.

The Evolution of Steel Making Technology

Steel making technology has undergone significant transformation over centuries, with each advancement bringing in a wave of efficiency and quality improvement. From manual forges to automated, high-tech operations, the evolution is a testament to human ingenuity and the relentless pursuit of progress.

In the early days, steel was produced in small quantities using primitive techniques. The introduction of the Bessemer process in the mid-19th century was a turning point, allowing for the mass production of steel for the first time. This method involved blowing air through molten iron to reduce the carbon content, a crucial step in producing strong, workable steel.

The next leap forward came with the basic oxygen steelmaking process in the 20th century. This innovation drastically reduced the time needed to convert iron into steel, using oxygen to purify the metal rapidly. It remains one of the most common methods of steel production today, reflecting enduring benefits despite its age.

Modern steel making has embraced high-tech solutions, such as computer control systems and process automation. These technologies enhance precision and consistency, allowing the steel industry to meet highly specific demands of different sectors. Sophisticated quality control mechanisms ensure that each batch of steel adheres to the exact specifications required by clients.

As we look to the future, steel production technology continues to evolve. Innovations such as electric arc furnace optimization and alternative iron-making technologies promise to reduce the industry’s environmental impact and enhance material properties. The industry's commitment to innovation ensures that steel making technology will continue to evolve, meeting the challenges of the 21st century and beyond.

Pros and Cons of Modern Steel Industry Technologies

| Advantages | Disadvantages |

|---|---|

| Reduction in Greenhouse Gas Emissions | High Initial Investment Costs |

| Improved Energy Efficiency | Technological Complexity |

| Enhanced Production Quality and Consistency | Need for Skilled Workforce |

| Minimization of Waste and Resource Usage | Possible Job Displacement due to Automation |

| Opportunities for New Markets and Products | Dependency on Technological Upgrades |

Key Innovations in Modern Steel Production

The modern era of steel production is characterized by remarkable technological breakthroughs that have reshaped the industry. Innovations in materials, processes, and equipment have paved the way for unprecedented levels of efficiency and environmental responsibility.

One of the significant breakthroughs in recent times is the development of ultra-high-strength steels. These materials have opened new frontiers in engineering and construction, allowing for lighter and more durable solutions without compromising safety or performance.

Advances in process technology, such as near-net-shape casting, mean that steel can now be cast with incredible precision, reducing the need for finishing work and saving on material waste. This precision casting technique has become crucial for industries where material specifications are measured down to a fraction of an inch.

On the environmental front, CO2 capture and storage technologies are being integrated into the steel making process. These systems aim to mitigate the environmental impact of steel production by trapping the carbon dioxide produced during the process and preventing it from entering the atmosphere.

Finally, the digital transformation of the steel industry cannot be overlooked. The integration of IoT (Internet of Things) devices and smart analytics has led to smarter steel mills that can predict maintenance needs, optimize energy consumption, and enhance the overall production process. These digital tools not only improve operational efficiency but also contribute to the production of higher-quality steel.

Each innovation builds upon the last, ensuring the continued relevance and vitality of the steel production industry in an increasingly competitive and sustainable economy.

Steel Production New Technology: Shaping the Future

The future of steel production is poised to be radically different from today, primarily through the adoption of new technology designed to address the chalIenges of modern demand and environmental constraints. A shift in focus towards more sustainable and efficient processes is leading to disruptive innovations in the steel industry.

One emerging technology that holds great promise is the use of hydrogen as a reduction agent in steel making. This shift away from traditional carbon-based materials for reduction has the potential to revolutionize the industry by virtually eliminating CO2 emissions from the steel making process.

Electromagnetic casting is another advancement making waves in the sector. By utilizing powerful magnets, this process allows for the continuous casting of steel with increased control over solidification, resulting in improved material properties and surface quality.

A significant focus on energy recovery systems is also central to new steel production technology. These innovative systems capture and reuse the vast amounts of heat generated during steel making, leading to substantial energy savings and a smaller carbon footprint.

Digitalization continues to play a critical role, with technologies such as machine learning and big data analytics providing insights that drive optimizations across the entire production chain. These digital tools help in not just monitoring but also predicting the steel making processes, allowing for proactive adjustments and continuous improvement.

In concIusion, the infusion of new technology into steel production is not just enhancing the capabilities of current methodologies but is laying a foundation for a cleaner, more sustainable industry well equipped to meet the future's challenges head-on.

The Role of Automation and AI in Steel Manufacturing

The integration of automation and Artificial Intelligence (AI) is transforming steel manufacturing into a realm of precision and efficiency previously unattainable. These technologies are fundamental in redefining the capabilities of the steel industry, allowing for higher production rates with reduced costs and improved safety.

Automation in steel plants has taken over repetitive and hazardous tasks, leading to fewer workplace accidents and consistent product quality. Automated machinery, equipped with sensors and actuators, performs tasks such as material handling, temperature control, and finishing processes with minimal human intervention.

AI takes automation a step further by introducing elements of human-like reasoning. Machine learning algorithms analyze vast amounts of data to optimize various production parameters, such as energy consumption, raw material usage, and process durations. These systems are becoming increasingly adept at predicting equipment failures, allowing for timely maintenance and avoiding costly downtimes.

In quality control, AI-powered visual inspection systems provide real-time monitoring of steel surfaces, identifying imperfections that are imperceptible to the human eye. This technology ensures that the steel not only meets established standards but also exceeds customer expectations in terms of quality and reliability.

As steel manufacturers continue to move towards Industry 4.0, the role of automation and AI will become more pronounced, providing a competitive edge through smart factories capable of making informed, data-driven decisions. The future of steel manufacturing is one where the fusion of advanced technologies delivers outcomes that benefit producers, consumers, and the environment alike.

Sustainable Practices in Steel Production

Sustainability in steel production is no longer optional but a critical factor that shapes the industry's future. It encompasses the necessity to reduce environmental impact while fulfilling the material needs of modern society. The steel industry is actively adopting sustainable practices that minimize its carbon footprint and improve resource efficiency.

One of the methods gaining traction is the recycling of steel. Recognized as the world's most recycled material, steel's durability and recyclability make it an environmentally friendly choice. Steel plants are increasingly utilizing scrap steel, which requires significantly less energy to process compared to raw materials and cuts down on waste.

Alongside recycling, the push for resource conservation is evident in initiatives aimed at lowering water usage and optimizing raw material consumption. Innovative water treatment plants allow for the reusing of water within steel manufacturing facilities, thus conserving this vital resource.

The adoption of alternative energy sources is another sustainable practice revolutionizing steel production. The industry is gradually shifting from non-renewable resources to options like solar, wind, and bioenergy to power operations, thereby reducing dependence on fossil fuels.

In line with the circular economy model, steel production is exploring the use of by-products. Slag, a by-product of the steel making process, is being repurposed for road construction and as a substitute for natural aggregates in cement production, contributing to an overall reduction in the industry's ecological footprint.

Through these sustainable practices, the steel industry is not only becoming more environmentally responsible but is also fostering innovation that ensures long-term viability. These strides are pivotal in maintaining the delicate balance between industrial advancement and environmental stewardship.

Challenges and Opportunities in Advanced Steel Making

As the steel industry ventures into an era of advanced steel making, it faces a unique set of challenges and opportunities that will define its pathway to progress. These factors are crucial in shaping the strategies that steel producers will employ to remain competitive and sustainable in a rapidly evolving market.

One of the foremost challenges is the escalating costs of raw materials and energy. Fluctuations in the global market can have a profound impact on steel production costs, compelling manufacturers to seek more stable and cost-effective solutions. In addition, stringent environmental regulations are also forcing the industry to rethink and innovate to stay compliant.

However, with challenges come opportunities, and one of these is the advancement in material science. Breakthroughs in developing new alloys and steel grades present a significant opportunity for the industry to cater to specialized and high-performance applications, such as in the aerospace and automotive sectors.

Additionally, there's an opportunity in forging stronger partnerships with the tech industry to integrate emerging technologies into steel making. This collaboration could lead to game-changing innovations that enhance the industry's efficiency and product offerings.

The global push towards infrastructure development presents another avenue for the steel industry to capitalize on. As nations invest in building and upgrading their infrastructure, the demand for steel could see an uptick, thus opening new markets and expanding the industry's reach.

In meeting these challenges and seizing upon the opportunities, the steel industry must be nimble, innovative, and forward-thinking, ensuring that advanced steel making not only thrives in the present but is also well-prepared for the future.

The Impact of Technology on Steel Quality and Efficiency

The relentless advance of technology has had a profound impact on both the quality of steel and the efficiency of its production. These technological strides have addressed age-old industry challenges while setting new standards in steel manufacturing.

Technological improvements in the refining and alloying processes have enabled producers to engineer steel with exceptional properties, such as increased strength-to-weight ratios, corrosion resistance, and durability. These advancements ensure that steel remains the material of choice for critical applications across various sectors.

In the realm of production efficiency, technologies like continuous casting have reduced turnaround times from ore to finished product. More sophisticated manufacturing processes have also led to considerable reductions in energy consumption, a key factor in the cost-intensive steel industry.

Emerging technologies such as predictive maintenance driven by AI algorithms have minimized unplanned downtime by anticipating equipment failures before they occur. This not only ensures continuous production flows but also extends the lifespan of critical machinery.

The culmination of these technological influences is a steel industry that produces higher quality materials more reliably and sustainably than ever before. As technology continues to evolve, it will inevitably continue to push the boundaries of what can be achieved in steel quality and manufacturing efficiency.

Case Studies: Success Stories in Steel Production Advancements

The steel industry has several illustrative examples of how technological advancements have driven success and innovation. Here we explore a few case studies that highlight the transformative impact of new technologies in steel production.

Case Study 1: The Integration of Electric Arc Furnace (EAF) Technology

A leading steel manufacturer revolutionized their production process by adopting EAF technology. This transition not only lowered their carbon emissions but also increased their scrap metal recycling rate significantly. The result was a double win for sustainability and cost-efficiency, positioning the company as a pioneer in environmentally conscious steel production.

Case Study 2: Application of AI in Quality Control

Another success story comes from a steel plant that implemented an AI-powered quality control system. By using machine learning to analyze images of steel surfaces during production, they were able to detect and address defects that previously went unnoticed. This technology substantially elevated the overall quality of their products and reduced waste, leading to an improved market reputation and customer satisfaction.

Case Study 3: Implementation of Continuous Casting Techniques

Continuous casting has been another ground-breaking technology embraced by the steel industry. A facility that switched to this method from traditional ingot casting significantly reduced their material waste and energy consumption. They were able to speed up the production process, enhance the structural integrity of their steel, and reduce costs, all while maintaining high-quality standards.

These case studies demonstrate the tangible benefits of investing in new steel production technologies. When companies are willing to innovate and embrace change, they often find that the risks pay off in the form of increased competitiveness, streamlined operations, and a stronger commitment to sustainability.

Looking Ahead: What's Next for Steel Production Technology?

Peering into the future of steel production, it's evident that technology will continue to be a driving force in shaping industry practices and products. Exciting developments are on the horizon, signaling a new era of innovation and refined manufacturing processes.

One eagerly anticipated trend is the rise of smart manufacturing ecosystems. These will feature interconnected machines and equipment that communicate in real-time to optimize the entire production line. This level of inter-connectivity and data analysis could lead to unprecedented optimization of steel production.

Advancements in 3D printing technology for steel are set to open new possibilities in manufacturing complex and customized steel products. This could revolutionize the way we think about design and construction, allowing for flexibility and innovation in structures and components.

Moreover, the industry is looking toward revolutionary smelting reduction techniques, which might eliminate the need for traditional blast furnaces entirely. These methods are expected to be more energy-efficient and environmentally friendly, drastically reducing the steel sector's carbon emissions.

Research into new forms of additive manufacturing and metallurgical processes is also ongoing, with the potential to create stronger and more lightweight steel at lower costs. The quest for material properties that can withstand extreme conditions is pushing steel production technology into new territories.

As we look to the future, it is clear that the steel industry will continue to evolve and adopt new technologies that not only enhance production capabilities but also address global environmental concerns. The path ahead is one of continual improvement, with technology leading the way to a brighter, more sustainable future for steel production.

Conclusion: Embracing Change in the Steel Industry

The journey through the advancements and innovations within the steel industry highlights an essential narrative of perpetual evolution. Embracing change is not simply an option but a strategic imperative for those within the steel sector. Technology has been the catalyst for transformative shifts in quality, efficiency, and sustainability.

As we reflect on the progression of steel production technology, it is evident that adaptation and continuous improvement have been paramount. The industry's willingness to invest in new technologies and rethink traditional methods has been crucial in its ability to address the challenges of a dynamic market and a planet with finite resources.

The intrinsic value of steel as a material remains undisputed, and its future production is set to be smarter, cleaner, and more integrated into the fabric of our technological society. In embracing these changes, the steel industry does not merely survive; it thrives and leads by innovative example, setting a standard for manufacturing sectors worldwide.

As stakeholders look to the horizon, they can do so with the confidence that the steel industry will continue to innovate and adapt, securing its place as a vital contributor to both the global economy and the advancement of human civilization.

The Cutting-Edge of Steel: Innovations Shaping Modern Production

What are the latest innovations in steel making technology?

The latest innovations in steel making technology include the use of Electric Arc Furnaces (EAFs) with Ultra High Power (UHP) technology, computer control systems for precise process adjustments, and the introduction of hydrogen as a reduction agent to reduce CO2 emissions. Continuous casting techniques and advanced quality control using AI for defect detection are also at the forefront of modernizing the steel production process.

How is automation impacting steel production efficiency?

Automation greatly enhances steel production efficiency by taking over repetitive, precise, and hazardous tasks. It introduces consistent quality and increased production rates, while reducing the likelihood of human error. Advanced sensors, robotic arms, and control systems streamline operations and minimize downtimes through predictive maintenance, further optimizing production efficiency.

What role does Artificial Intelligence play in steel manufacturing?

Artificial Intelligence (AI) plays a key role in steel manufacturing by analyzing data to optimize production processes, reducing waste, and conserving energy. AI enables predictive maintenance, anticipating machinery failures before they occur. It also improves quality control by utilizing machine learning algorithms for real-time defect detection, helping to ensure steel products meet rigorous standards.

How is the steel production industry addressing environmental sustainability?

The steel production industry is addressing environmental sustainability by adopting practices such as increased use of scrap metal recycling, integration of renewable energy sources, CO2 capture and storage technologies, and improvements in process efficiency to reduce energy consumption. These efforts aim to reduce the carbon footprint and overall environmental impact of steel production.

What future technologies are predicted to further transform steel production?

Predicted future technologies that could transform steel production include the use of hydrogen-based direct reduction methods to eliminate CO2 emissions and electromagnetic casting for improved steel properties. Additionally, energy recovery systems designed to capture and reuse heat from the production process, and further advancements in 3D printing may significantly influence the steel industry in the coming years.